Plant Replaces Aging DAFs with Sludge Thickening Centrifuges

Location: Kenosha Water Utility Wastewater Treatment Plant | Kenosha, Wisconsin

Plant Size: 28 MGD

Installation: 2011 (1) THK200 Sludge Thickener for WAS and 2015 (1) THK200 Sludge Thickener for Primary

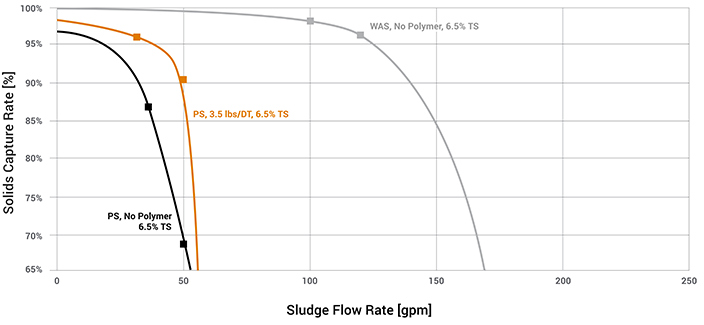

- Feed @ 0.9-1.1% TS

- WAS: 90-120 gpm

- Primary: 35-50 gpm

- 98% capture

- WAS: 0-1lb/DT polymer, seasonal use

- Primary: 0-4lbs/DT polymer, active

- 0.07 kW/gpm

- 5.5-6.5% TS TWAS

PROBLEM

Four aging DAFs occupied a substantial footprint and needed expensive rehabilitation. The DAF tanks released hazardous hydrogen sulfide (H2S) gas and the plant needed to increase digester capacity because of the low solids concentration. KWU WWTP is in the middle of a residential neighborhood. Only no-to-very low odor thickening technologies were considered for the plant upgrade.

RESULTS

- Installed two THK200s, one for WAS and one for primary sludge

- WAS THK required a 120 sq/ft footprint, reduced from the previous DAFs 5,000 sq/ft footprint

- Primary THK thickening for digester optimization

- WAS and primary both thicken sludge to 6-7%

- DAF/primary settling tanks previously thickened to 2-4%

- Reduced the digester volume from six to three digesters

- Eliminated the need to rehabilitate all six digesters

- Consistent thickened solids output enhances the PONDUS operation

- Typically no polymer used for WAS, up to 0-1lb/DT for seasonal use