Maintenance Log

Decanter Centrifuges

You've invested in the best of the best - a decanter centrifuge with top-of-the-line performance with the driest cake, highest G-volume and torque capacity. To make the most of your investment, it's critical to give your centrifuge the care and attention it deserves. Regular inspections and maintenance are just as important as a flawless installation when it comes to keeping your centrifuge running like new.

NOTE: Use this checklist as a reference only is the guidelines are for a Centrisys municipal wastewater centrifuge. Industrial applications may vary. Your centrifuge may vary. Consult your Operations & Maintenance manual or contact Centrisys/CNP for assistance.

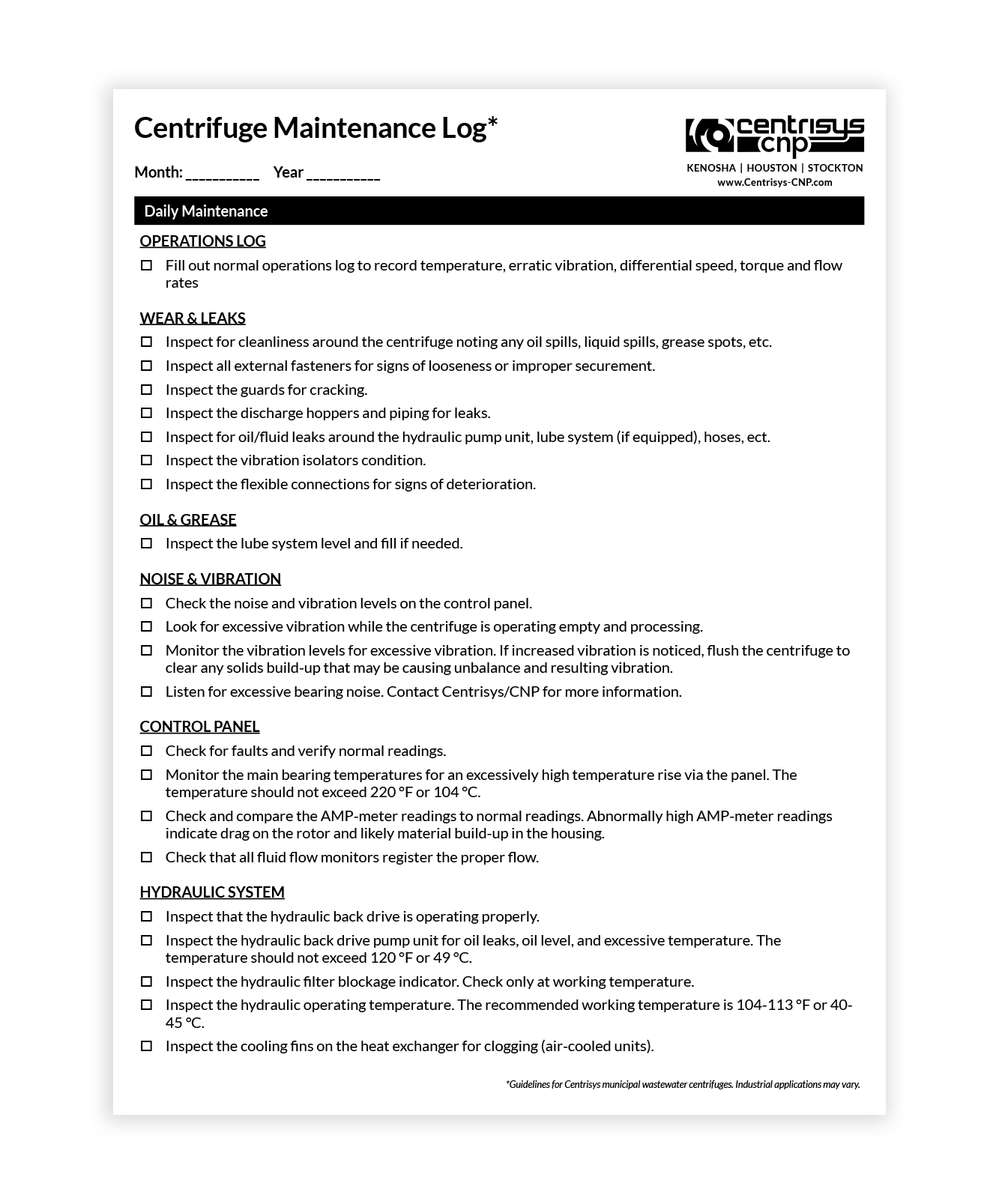

Download a Printable Centrifuge Inspection and Maintenance Log

This easy to use inspection and maintenance log will help your operators keep your centrifuge operating efficiently.

Daily Maintenance

| Operations Log |

| Fill out normal operations log to record temperature, erratic vibration, differential speed, torque and flow rates. |

| Wear & Leaks |

| Inspect for cleanliness around the centrifuge noting any oil spills, liquid spills, grease spots, etc. |

| Inspect all external fasteners for looseness or improper securement. |

| Inspect the guards for cracking. |

| Inspect the discharge hoppers and piping for leaks. |

| Inspect for oil/fluid leaks around the hydraulic pump unit, lube system (if equipped), hoses, etc. |

| Inspect the vibration isolators condition. |

| Inspect the flexible connections for signs of deterioration. |

| Oil & Grease |

| Inspect the lube system level and fill if needed. |

| Noise & Vibration |

| Check the noise and vibration levels on the control panel. |

| Look for excessive vibration while the centrifuge is operating empty and processing. |

| Monitor the vibration levels for excessive vibration. If increased vibration is noticed, flush the centrifuge to clear any solids build-up that may be causing unbalance and resulting vibration. HOW TO: Use the Centrifuge Cleaning Modes |

| Listen for excessive bearing noise. Contact Centrisys/CNP for more information. |

| Control Panel |

| Check for faults and verify normal readings. |

| Monitor the main bearing temperatures for an excessively high temperature rise via the panel. The temperature should not exceed 220 °F or 104 °C. |

| Check and compare the AMP-meter readings to normal readings. Abnormally high AMP-meter readings indicate drag on the rotor and likely material build-up in the housing. |

| Check that all fluid flow monitors register the proper flow. |

| Hydraulic System |

| Inspect that the hydraulic back drive is operating properly. |

| Inspect the hydraulic back drive pump unit for oil leaks, oil level, and excessive temperature. The temperature should not exceed 120 °F or 49 °C. HOW TO: Maintain Your Hydraulic Pump |

| Inspect the hydraulic filter blockage indicator. Check only at working temperature. |

| Inspect the hydraulic operating temperature. The recommended working temperature is 104-113 °F or 40-45 °C. |

| Inspect the cooling fins on the heat exchanger for clogging (air-cooled units). |

Daily Maintenance

| Operations Log |

| Fill out normal operations log to record temperature, erratic vibration, differential speed, torque and flow rates. |

| Wear & Leaks |

| Inspect for cleanliness around the centrifuge noting any oil spills, liquid spills, grease spots, etc. |

| Inspect all external fasteners for looseness or improper securement. |

| Inspect the guards for cracking. |

| Inspect the discharge hoppers and piping for leaks. |

| Inspect for oil/fluid leaks around the hydraulic pump unit, lube system (if equipped), hoses, etc. |

| Inspect the vibration isolators condition. |

| Inspect the flexible connections for signs of deterioration. |

| Oil & Grease |

| Inspect the lube system level and fill if needed. |

| Noise & Vibration |

| Check the noise and vibration levels on the control panel. |

| Look for excessive vibration while the centrifuge is operating empty and processing. |

| Monitor the vibration levels for excessive vibration. If increased vibration is noticed, flush the centrifuge to clear any solids build-up that may be causing unbalance and resulting vibration. HOW TO: Use the Centrifuge Cleaning Modes |

| Listen for excessive bearing noise. Contact Centrisys/CNP for more information. |

| Control Panel |

| Check for faults and verify normal readings. |

| Monitor the main bearing temperatures for an excessively high temperature rise via the panel. The temperature should not exceed 220 °F or 104 °C. |

| Check and compare the AMP-meter readings to normal readings. Abnormally high AMP-meter readings indicate drag on the rotor and likely material build-up in the housing. |

| Check that all fluid flow monitors register the proper flow. |

| Hydraulic System |

| Inspect that the hydraulic back drive is operating properly. |

| Inspect the hydraulic back drive pump unit for oil leaks, oil level, and excessive temperature. The temperature should not exceed 120 °F or 49 °C. HOW TO: Maintain Your Hydraulic Pump |

| Inspect the hydraulic filter blockage indicator. Check only at working temperature. |

| Inspect the hydraulic operating temperature. The recommended working temperature is 104-113 °F or 40-45 °C. |

| Inspect the cooling fins on the heat exchanger for clogging (air-cooled units). |

Weekly Maintenance

| Wear & Leaks |

| Operate the centrifuge once a week, even to simply start the centrifuge up and then shut the centrifuge back down. HOW TO: Prevent Condensation in Your Decanter Centrifuge |

| Inspect the drive belt tension for stretch or excessive deflection. Re-tighten or replace as necessary. See your Operations & Maintenance manual. |

| Inspect for abrasions on the hydraulic hoses. Protect the hoses from chafing. HOW TO: Maintain Your Hydraulic Pump |

| Remove the feed tube and check for wear and build-up inside the centrifuge opening. |

| .Oil & Grease |

| Grease the internal bearings. See your Operations & Maintenance manual. HOW TO: Grease the Internal Bearings |

| Purge the internal bearings. Refer to section 8 of your Centrisys Operations & Maintenance manual. |

Monthly Maintenance

| Wear & Leaks |

| Open the centrifuge top cover, remove the safety covers, and inspect the rotor and housing for wear. HOW TO: Know if Your Centrifuge has Struvite Formation |

| Inspect the solids and liquids discharge areas. Remove any accumulated solids. HOW TO: Flush Your Centrifuge |

| Inspect the wiring, electrical cords, etc. for wear or damage. Replace if necessary. |

| Inspect all areas where water can collect on the centrifuge. HOW TO: Prevent Condensation in Your Decanter Centrifuge |

| Inspect solids discharge ports on the conical and scroll conveyor flights for excessive wear on the front of the flight. This may be checked throughout the solids discharge ports by removing the solids upper housing. Worn discharge ports may indicate a worn scroll as well, causing an unbalanced centrifuge and centrifuge damage. HOW TO: Visually Inspect Solids Discharge Nozzles |

| Noise & Vibration |

| Verify the vibration levels are at or below normal operating levels on the panel display. |

| Control Panel |

| Check the filter system. Replace the filter if necessary. |

| Lube System & Hydraulic Pump Unit |

| Take a small sample from the drain to visually check the oil for color and contamination. HOW TO: Maintain Your Centrifuge Hydraulic Pump HOW TO: Check for Water in the Oil |

Every 4,000 Operating Hours or 6 Months of Operation Maintenance

| Wear & Leaks |

| Inspect the hydraulic drive for external leaks. |

| Perform an efficiency check on the hydraulic pump unit and Rotodiff. With an empty centrifuge, verify that the actual differential speed follows the commanded differential speed. HOW TO: Verify Your Differential Speed |

| Control Panel |

| Check the filter system and replace the filter if necessary. |

| Hydraulic System |

| Change the hydraulic pump unit’s oil and oil filter. Use only recommended hydraulic oils. See your Operations & Maintenance manual. HOW TO: Maintain Your Centrifuge Hydraulic Pump |

| Change or clean the hydraulic drive suction strainer, only on hydraulic pump units with gear pumps. HOW TO: Maintain Your Centrifuge Hydraulic Pump |

| Clean the hydraulic drive oil tank. |

Every 15,000 Operating Hours or Every 5 Years of Operation Maintenance

| Wear & Leaks |

| Replace the main bearings and seals. HOW TO: Check the Main Bearings HOW TO: Diagnose Bearing Damage |

| Remove and inspect the scroll for wear and damaged components. HOW TO: Understand the Different Types of Spare Rotating Assemblies |

| Inspect and change the bearings and seals on the Rotodiff hydraulic motor or gearbox. |

| Balance the bowl to specification. HOW TO: Change Your Bowl Direction |

| Balance the scroll to specification. HOW TO: Choose the Correct Balancer |

| Inspect the feed nozzles for wear. Replace if necessary. |

| Inspect the discharge nozzles for wear. Replace if necessary. HOW TO: Visually Inspect Discharge Nozzles |

| Inspect the scroll tiles for wear. Replace if necessary. |

| Inspect the feed chamber area for wear. Replace worn components if necessary. |

| Control Panel |

| Inspect the breakers, relays, PLCs, I/O cards, transformers, HMIs, and VFDs. It may be time to upgrade your electrical components to increase efficiency. |

| Inspect all electrical components, wires, and terminals for identifier labels. Replace missing labels if necessary. |

| Inspect that all electrical components are clear and separated from each other. Fix any components if necessary. |

| Inspect the enclosure and back panels for dust. Remove any built-up dust. |

| Inspect the control panel for rust or pest presence. Perform the necessary measures to prevent rust and pest presence. |

Contact Us to Learn More About Dewatering Decanter Centrifuge

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren.