About Us

What Makes Centrisys/CNP Different From Other Wastewater Treatment Providers?

Centrisys/CNP offers innovative solutions to address current and future environmental challenges. Their USA headquarters in Kenosha, Wisconsin, provides advanced decanter centrifuge manufacturing, service and cutting-edge biosolids processes that are internationally recognized.

The many differences in wastewater processing make optimization and customization a key differentiator for Centrisys/CNP. Our process starts with the following:

- Listening to customers and consulting engineers to understand the plant goals and challenges

- Lab analysis for the abrasiveness, corrosiveness, and nature of the solids

- Evaluating the plant and sludge conditions of each operation

- Pilot testing at municipal or industrial plants

- Adapting the centrifuge design or treatment process based on the lab, pilot test and site conditions

- Prototyping and testing design concepts in SOLIDWORKS

Centrisys/CNP brings decades of expertise and innovation in centrifuge technology and resource recovery systems to every partnership. Our high-performance solutions are built on real-world experience, ensuring reliability, efficiency, and a tailored approach to meet your specific needs.

We pride ourselves on reducing operational costs, improving performance, and offering dedicated customer support throughout the lifecycle of our products. With a focus on continuous improvement and customized solutions, Centrisys/CNP is a trusted partner for optimal results in the wastewater and sludge treatment industry.

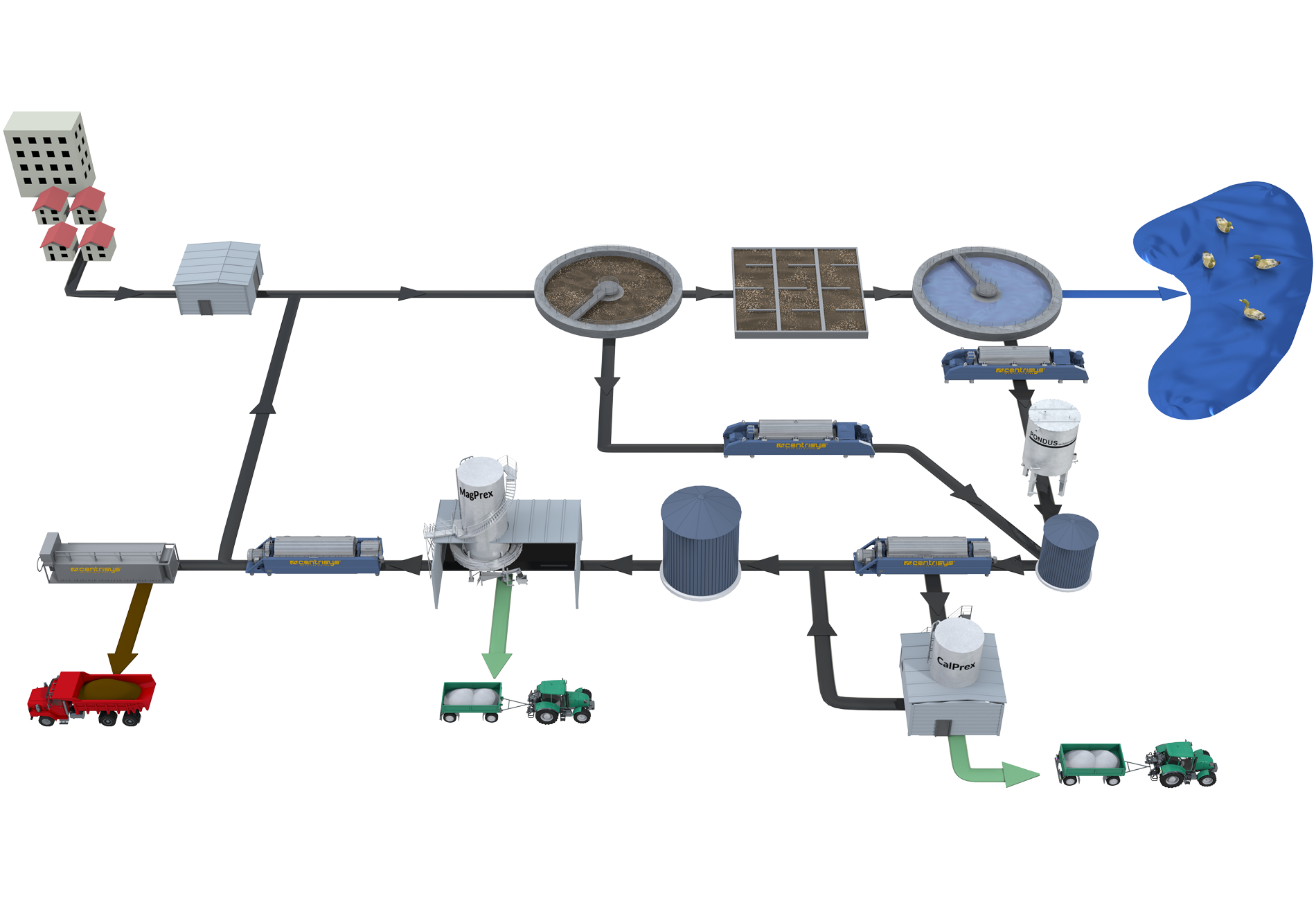

A vital part of Centrisys’ story is the formation of CNP - developed in 2014 with the goal of supplying phosphorous recovery, struvite removal, and a thermal hydrolysis process for enhanced sludge treatment to municipal and industrial plants.

Our approach to treating wastewater, municipal sludges, and industrial slurries is effective because it combines our equipment-manufacturing and centrifuge-service expertise with our knowledge of biosolids processes. It's the combination of equipment optimization and process expertise that provides the biggest advantages to municipal and industrial plants.

The Centrisys/CNP portfolio combines environmental processes and equipment for sludge and biosolids handling. The biggest advantage for municipal and industrial plants is our fusion of equipment knowledge and expertise with treatment processes.

Significant benefits are unlocked by understanding how these technologies interact and aligning them towards a plant's goals.

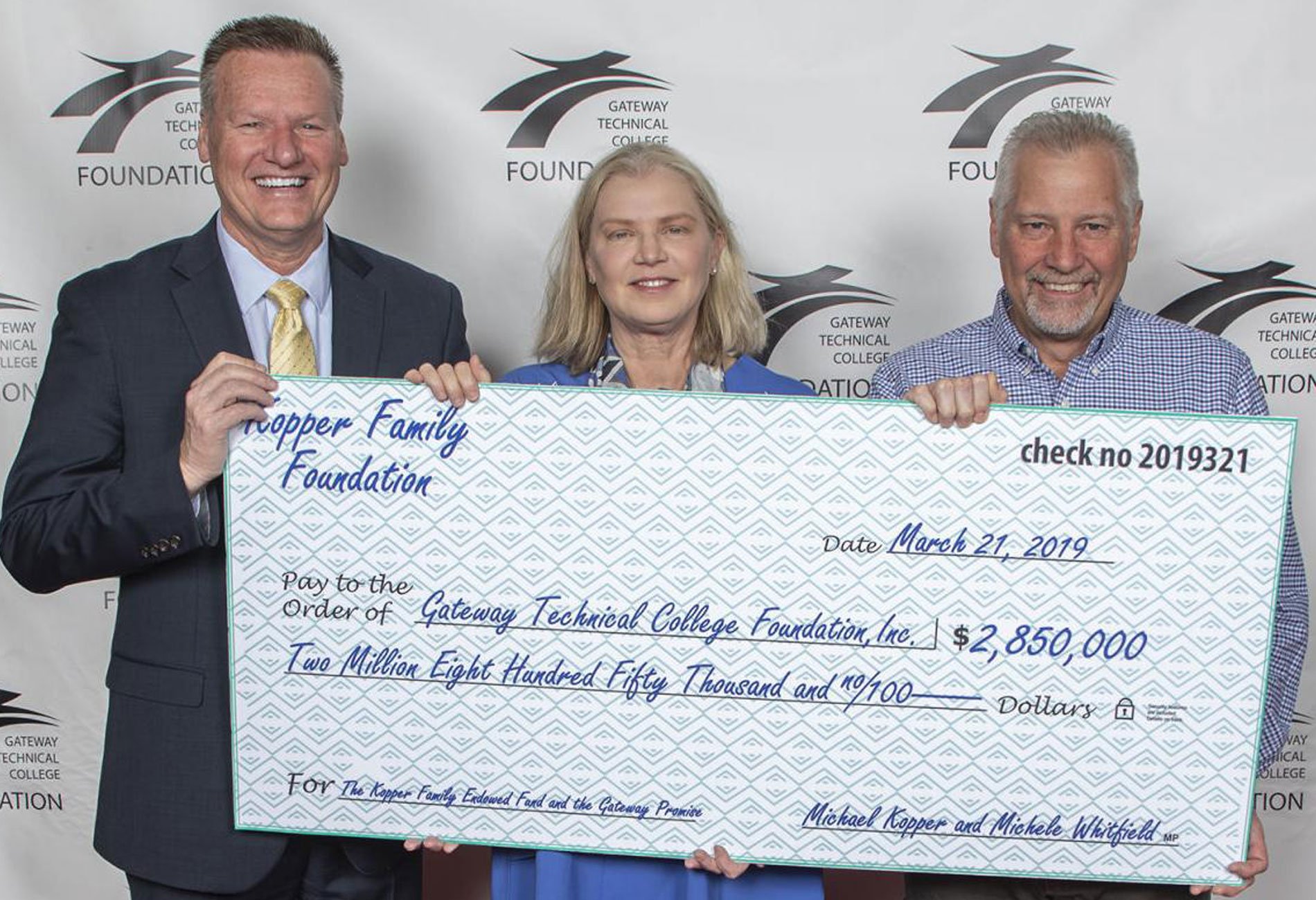

Centrisys/CNP is committed to empowering those within our community and beyond, with a focus on supporting environmental leaders of tomorrow and contributing to meaningful causes. Our dedication to giving back is reflected in various initiatives, from sponsoring educational programs and contests to providing scholarships and supporting charitable organizations. Through these efforts, we aim to foster innovation, education, and positive change in the water and wastewater industry while also making a difference in the lives of underprivileged children and local communities.

At Centrisys/CNP, our success is driven by a team of industry experts who are passionate about delivering innovative solutions in wastewater and biosolids treatment. From engineering to customer support, every team member is committed to advancing technology that makes a positive impact on the environment and industries we serve. Meet the talented professionals and discover how their expertise and passion sets us apart.

40+ Years of Biosolids and Wastewater Innovation

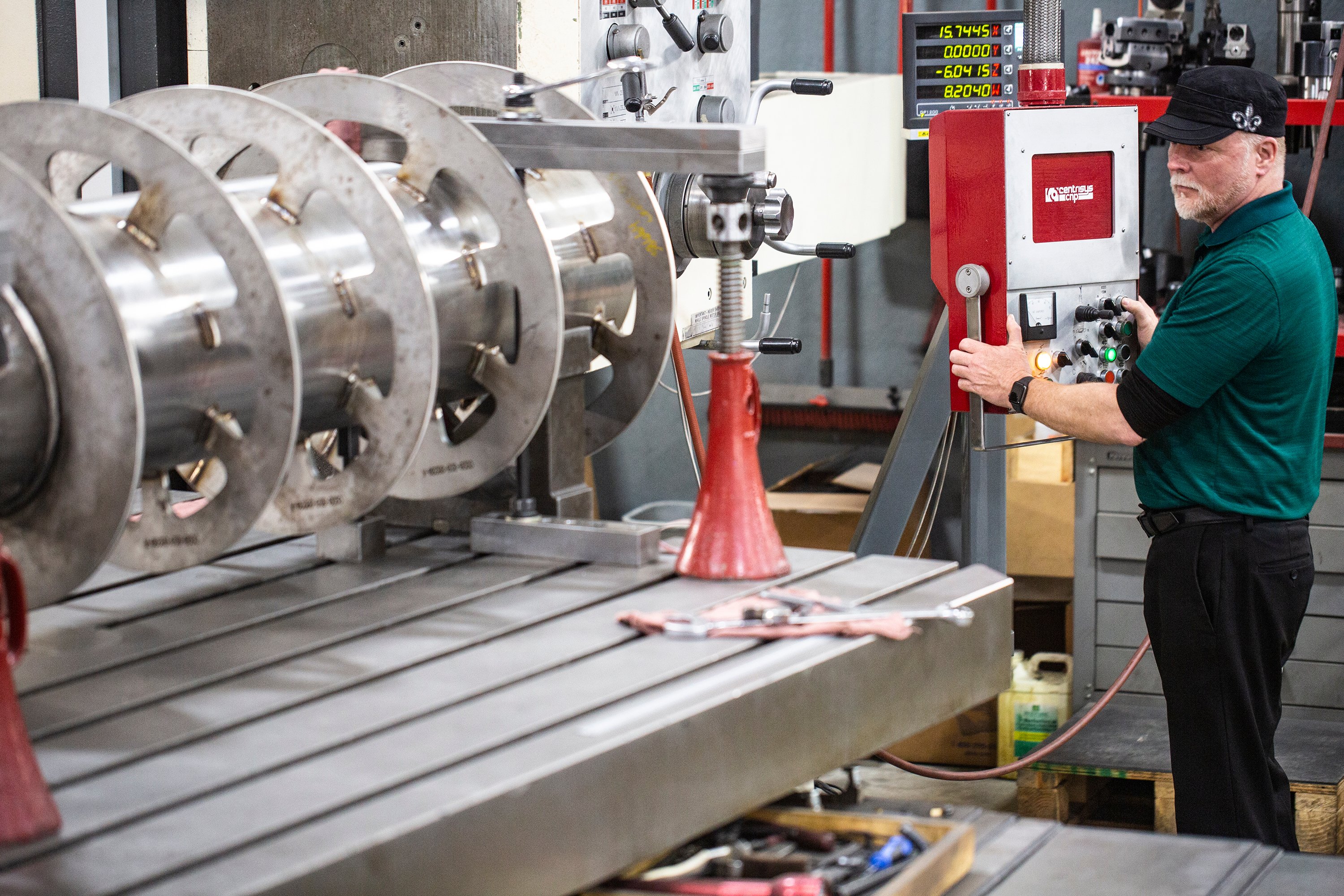

Established in 1987, Centrisys began by servicing and repairing decanter centrifuges manufactured by our competitors.

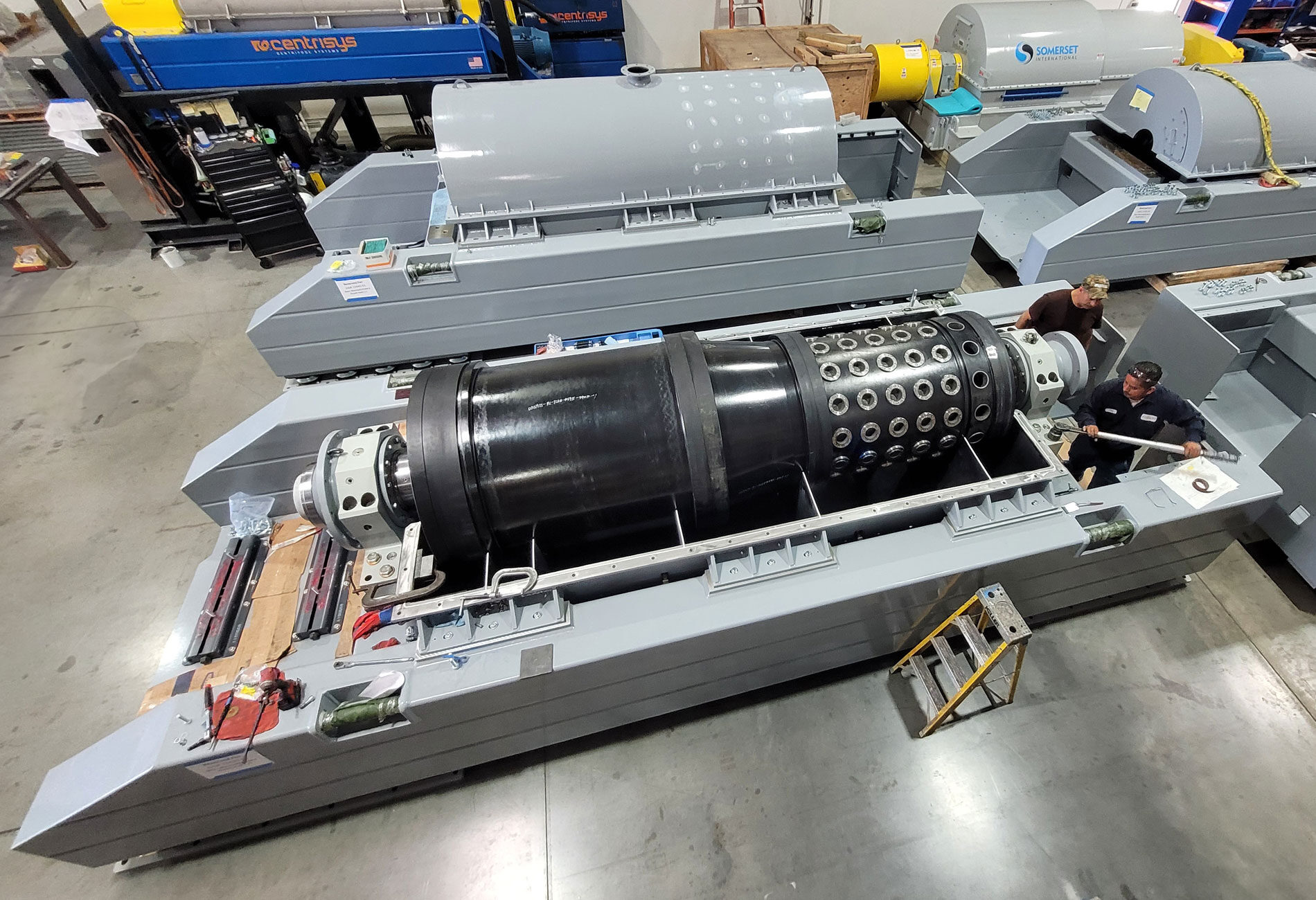

Due to customer demand, Centrisys began manufacturing centrifuges soon after and quickly became an expert in centrifuge technology. Centrisys/CNP offers standard, adaptable, and custom decanter centrifuge designs. The introduction of the DLT Dryer to the equipment portfolio is an innovative development that addresses industry-specific sludge challenges.

Centrisys/CNP's Wisconsin facility features a 20,000-square-foot centrifuge parts warehouse and distribution center with over $9M of spare parts in stock. Two additional U.S. service facilities are located in Stockton, California and Houston, Texas with six service and repair locations worldwide.

- Michael Kopper founded Centrisys Corporation in Libertyville, Illinois, focusing on decanter centrifuge service and repair for all brands.

- Began the Viscotherm partnership and installed the first Rotodiff® hydraulic backdrive retrofit.

- Designed and built the first CS Series decanter centrifuge for Honolulu, Hawaii.

- Developed a 3-phase dewatering centrifuge for crude oil recovery and tank bottom applications.

- Relocated the company headquarters to Kenosha, Wisconsin, with a 21,000 sq. ft. building.

- Opened a centrifuge service and repair center in Benicia, California.

- Doubled the Kenosha, Wisconsin headquarters building to 45,000 sq. ft.

- Purchased Team Metal Fabricating to increase Kenosha, Wisconsin machining capacity.

- Went global with the first dewatering centrifuge installations in Germany, China, and South America.

- Named Wisconsin Manufacturer of the Year for Operational Excellence.

- Opened a centrifuge service and repair center in Oftersheim, Germany.

- Opened a 20,000 sq. ft. West Coast centrifuge service and repair center in Stockton, California.

- Formed a partnership with Chengdu Tianbao Heavy Co. Ltd. and established a joint venture facility for production, sales, repair, and service in Chengdu, China.

- Opened a centrifuge service and repair center in Singapore.

- Expanded the Kenosha, Wisconsin headquarters to 66,000 sq. ft.

- Received the Economic Impact Award for business growth in Kenosha.

- Launched the THK Series sludge thickener for waste activated sludge (WAS), providing an innovative technology specifically designed for sludge thickening

- Expanded corporate headquarters to 95,000 sq. ft. with a third warehouse and distribution facility for centrifuge spare parts.

- Michael Kopper was named Milwaukee BizTimes Bravo! Entrepreneur Award winner.

- Installed the 2,000th Rotodiff hydraulic backdrive.

- Received the WEF Innovative Technology Award for the THK Series sludge thickener.

- Launched CNP – Technology Water and Biosolids Corporation for nutrient recovery and removal.

- Secured exclusive North American distribution for PONDUS™ and AirPrex® (now MagPrex™) phosphorus recovery technologies.

- Expanded into the Asian market through a strategic partnership with Chengdu Techcent Environment Co. Ltd.

- Completed the first North American waste-to-energy project at Kenosha Water Utility, featuring PONDUS, CS Series, THK Series, and a low-temperature belt dryer.

- Received the U.S. Environmental Protection Agency (EPA) Nutrient Recycling Challenge Award for AirPrex in the manure industry.

- Acquired exclusive worldwide licensing for CalPrex® pre-digestion phosphorus recovery process.

- Won the American Council of Engineering Companies (ACEC) Grand Award for the Kenosha Water Utility Optimization Project.

- Introduced the CS6-4 (smallest) and CS44-4 (largest) centrifuges.

- Expanded machining and fabrication capacity at the Kenosha headquarters.

- Was named Utility of the Future Today Recognition Program for the Kenosha Water Utility Optimization Project.

- Installed the first-of-its-kind centrifuge balancing bunker.

- Completed a 35,000 sq. ft. expansion to the second building in Kenosha, increasing headquarters to 130,000 sq. ft. and employing 150+ people worldwide.

- Installed 16 CS26-4 dewatering centrifuges at Hunts Point Installation, reducing electricity consumption by 60% and lowering operating costs by $1.7 million.

- Completed the MagPrex installation and eight CS26-4 dewatering centrifuges at Metro Water Recovery in Denver.

- Introduced the DLT Series, a dual belt, low-temperature belt dryer to further advance advanced dewatering efficiency.

- Received the Water Environment Federation (WEF) Operational and Design Excellence Award for the Denver Metro Water Recovery Nuisance Struvite and Dewaterability Improvement project.

- Michael Kopper and his leadership team reacquired full ownership of Centrisys, retaining every employee.

- Was named Wisconsin Manufacturer of the Year — Grand Award Winner

- Opened a 35,750 sq. ft. centrifuge service and repair center in Houston, Texas, expanding service capabilities.

- Received the Wisconsin Manufacturers & Commerce (WMC) Business Friend of the Environment Award for Sustainability.

- Centrisys/CNP opens new Engineering Innovation Lab in Kenosha, WI. An investment in sustainable growth, optimized collaboration, and advanced engineering practices.

- Engineered & Manufactured a brand new CS 44 Ft Screen Bowl.

Be Part of the Future

Our portfolio is an innovative approach to sludge and biosolids handling, which helps reduce the environmental footprint for generations to come. The Centrisys/CNP team of experts design, build, sell and service our equipment and processes. Want to join our team to be part of the future?