Fines | Tailings | Slurry Separation

Mining & Minerals:

Efficient Tailings Management Solutions

Effective Revenue Recovery

Success in the mining industry is a combination of using the best equipment and working with a partner who goes above and beyond to help you address your toughest challenges and take advantage of your biggest opportunities. That partner is Centrisys.

Each project begins with a consultation, samples analysis and an assessment of the site conditions. Based on this information, our engineers use state-of-the-art 3D CAD software SOLIDSWORKS to design a centrifuge or complete system to meet the needs of each mining project. Whether it's coal plant fines dewatering, aggregate and mineral tailings dewatering or sludge and residuals slurry separation, we never lose site of our customers goals for the final product or what the environmental solution needs to be.

Sharing a Vision Leads to Success

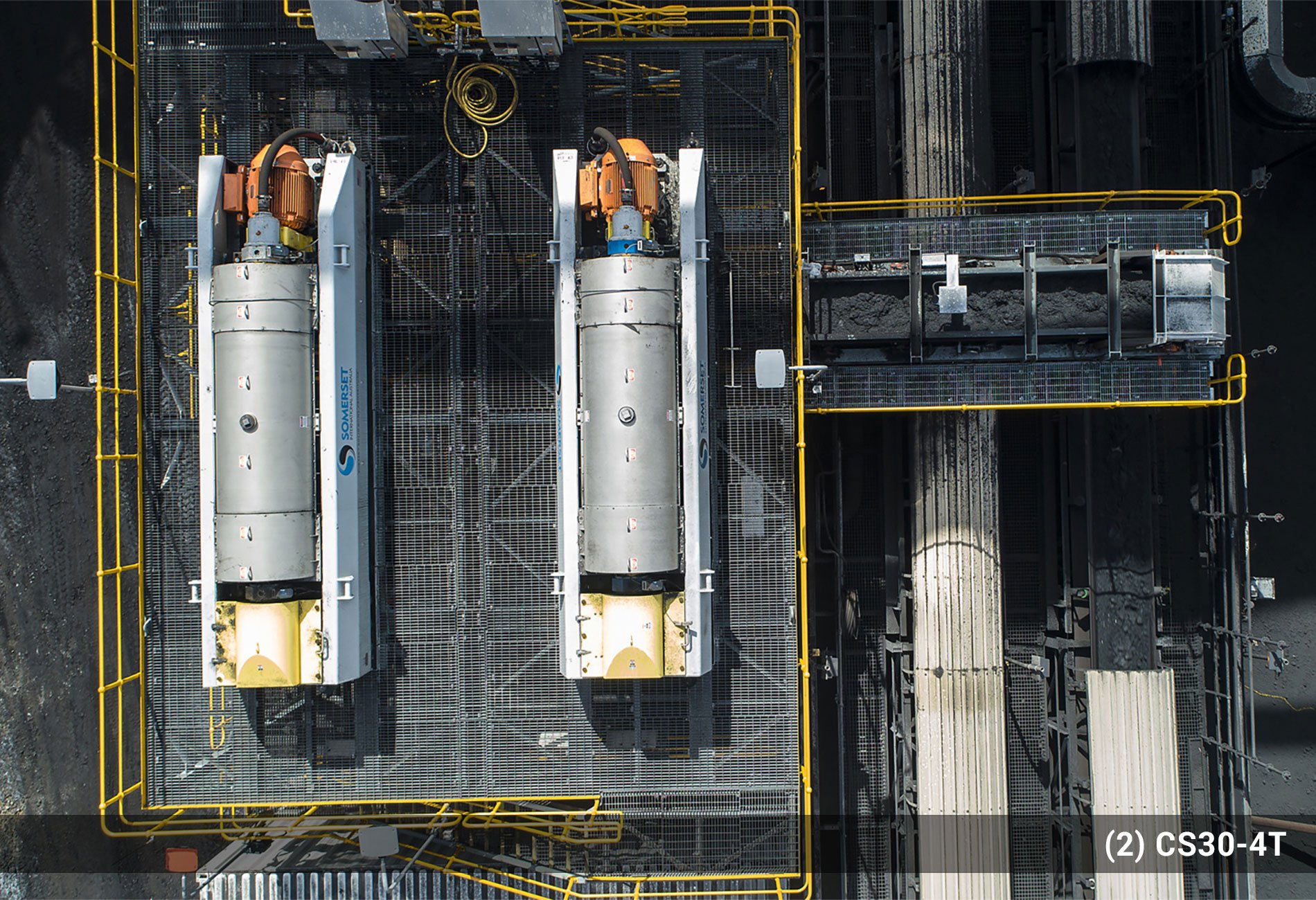

Somerset International partners with Centrisys to develop a breakthrough for fine coal recovery. The Sub325® is the result of that shared vision for innovation and improvement to deliver consistent moisture between 15% and 23%.

All Mines are Different

Each Site is as Individual as the Operation Itself

A standard "one size fits all" centrifuge design doesn’t work when the water flow requirements of each site may be different or other variations like: operating depths, varying product pH levels, temperature, corrosive and abrasive nature of the solids, size distribution, content percentage and specific gravity. All these affect what centrifuge will provide optimal performance. At Centrisys, we evaluate if the best option is a standard, semi-standard or a custom centrifuge for processing mineral materials and to reach the goals for the final product.

Tailings Management

Let’s keep this simple. Successful tailings centrifuges are about swallowing large amounts of solids in a robust design and then reduce the moisture content to improve the harvest of minerals and lower the environmental impact.

The Centrisys standard is a high-torque decanter centrifuge that allows for continuous monitoring and adjustment based on the load. This adjustment is achieved thru the Rotodiff® hydraulic scroll drive. The solids are retained under G-force for as long as possible. This allows for higher capacity and improves the moisture content of the solids discharge and creates drier, stackable solids and cleaner centrate.

More Uptime Equals Increased Capacity

A centrifuge is a continuous operation requiring less maintenance than other types of dewatering equipment. With no wash-water or filters to clean, mines can boost productivity with fewer disruptions to clean equipment.

Efficient | Robust | Reliable

It’s critical that mining dewatering equipment is efficient, reliable, has a low-cost of ownership over its lifespan and requires minimal maintenance. Highest quality materials of construction and advanced wear protection are standard features, not options, on a Centrisys centrifuge.

Request a CSI Centrifuge Inspection

Key Design Considerations in Mining + Mineral Applications

For improved handling of the aggressive slurries in mining and minerals, there are centrifuge design and product features that cannot be overlooked. We leverage what we have learned in the field along with our expertise in centrifuge technology to design the most robust centrifuge on the market today.

- Housing: Stainless steel is our standard. Fiberglass is not recommended due to its low tolerance to impact

- Scroll Body: Duplex stainless steel is the Centrisys standard

- Scroll Flights: The entire scroll length is protected with tungsten carbide tiles and/or fused carbide flame. A fully tiled scroll is recommended for abrasive slurries

- Bowl Center Section: The Centrisys standard is one piece, centrifugally cast duplex stainless steel. Super duplex stainless steel is recommended for low pH and high chloride applications

- Bowl Internal Protection: We use stainless steel or ceramic wear stripes. Ceramic hex tiles are recommended for extremely aggressive slurries

- Lubrication System: Customized for environment and application specifics, our standard is air/oil for large centrifuges and grease lubrication for small centrifuges. Air mist is recommended in cold climates

- Wear Components: Tungsten carbide and silicon carbide is used for all wear parts (nozzles, flight edges) that have contact with product

- Control Panel Options: Class1/Div. 1 (explosive gases present), Class1/Div. 2 (explosive gases possible), Full Hydraulics with Nema 7 Explosion-Proof Panel, VFD with NEMA 4X Purged Panel

- PLC Program Options: Allen Bradley, Siemens, Modicon PLC, AutomationDirect

Literature

- Sludge Reduction Technologies for Plants of All Sizes

- Get More from your Centrifuge

- 9 Reasons to Choose Centrisys

- The Centrisys-Viscotherm Scroll Drive is the Most Efficient in the Centrifuge Industry

- Energy-Efficient 3-Phase Separation

- Recover Base Fluids and Reduce Hydrocarbons

- The Right Dewatering Solution, the Fastest Payback, Lowest Cost of Ownership

- Complete Self-Contained Mobile Trailer Systems

- High Performance Skid Systems

- Centrisys THK Sludge Thickener Lease+ Program

- The Lowest Total Cost of Ownership in the Industry

- Enhance Environmental Performance

- CSI: A 40+ Point Centrifuge Inspection Program

- Decanter Centrifuge Parts Available When You Need Them

- Urgent Centrifuge Repair Response, Because You Can't Afford to Wait

- Enhance Performance and Extend the Life of your Decanter Centrifuge

Videos

General Arrangements

- THK600 Sludge Thickener Centrifuge

- THK350 Sludge Thickener Centrifuge

- THK200 Sludge Thickener Centrifuge

- CS30-4T 2-Phase Decanter Centrifuge

- CS26-4DT 2-Phase Decanter Centrifuge

- CS21-4HC DT 2-Phase Decanter Centrifuge

- CS21-4T 2-Phase Decanter Centrifuge

- CS21-4HC 2-Phase Decanter Centrifuge

- CS18-3 2-Phase Decanter Centrifuge

- CS26-4EV 2-Phase Decanter Centrifuge

- CS26-4 2-Phase Decanter Centrifuge

- CS21-4 2-Phase Decanter Centrifuge

- CS18-4 2-Phase Decanter Centrifuge

- CS30-4 2-Phase Decanter Centrifuge

Contact Us to Learn More About Centrisys/CNP's Capabilities

We're dedicated to providing innovative solutions that enhance the efficiency and effectiveness of your processes. Whether you're looking to optimize performance, reduce operational costs, or explore our industry-leading technology, our team is here to help.