Sewage Sludge Thickener

THK Series

Centrisys' THK Series Sewage Sludge Thickener is Specifically Engineered to Achieve High-Performance Thickening of Biosolids.

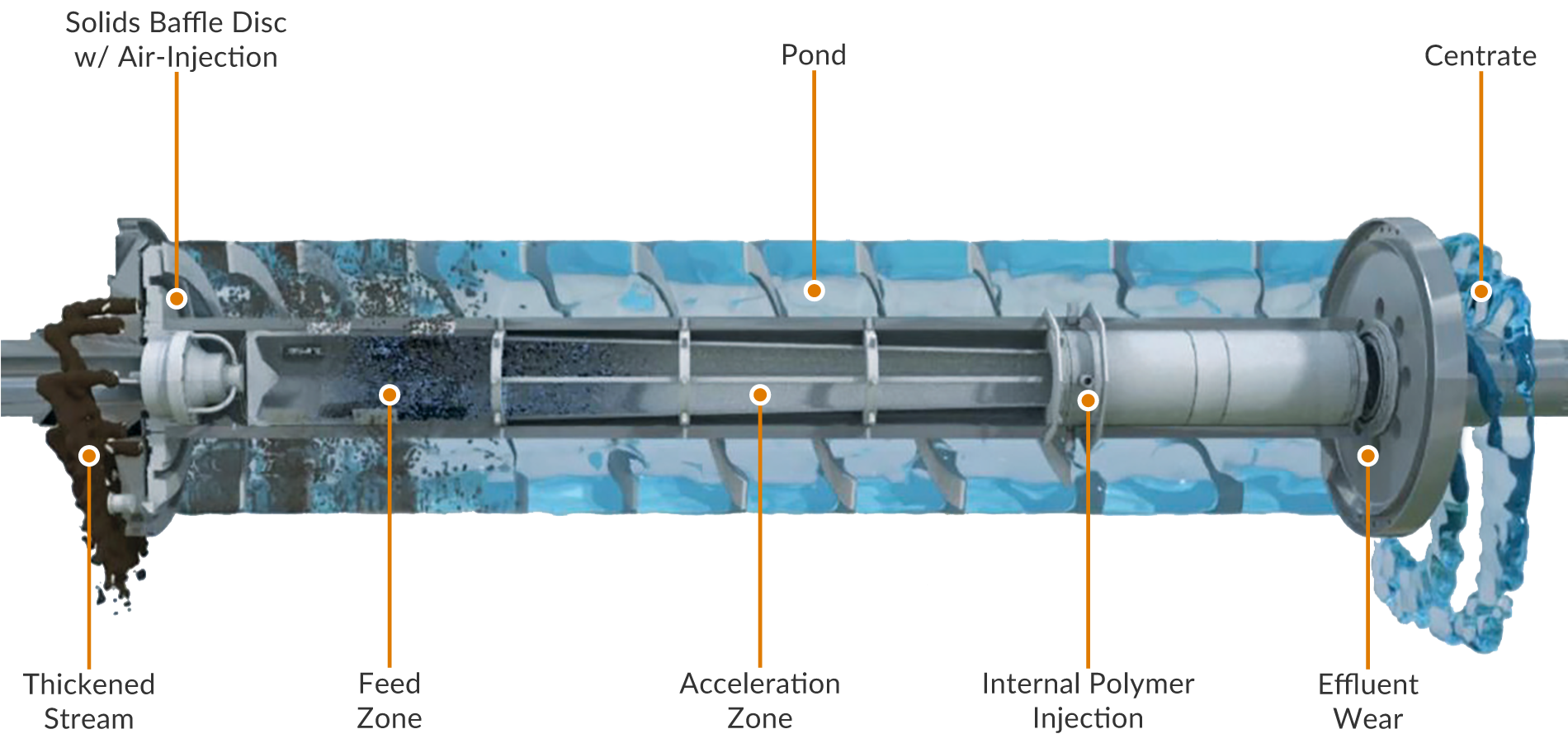

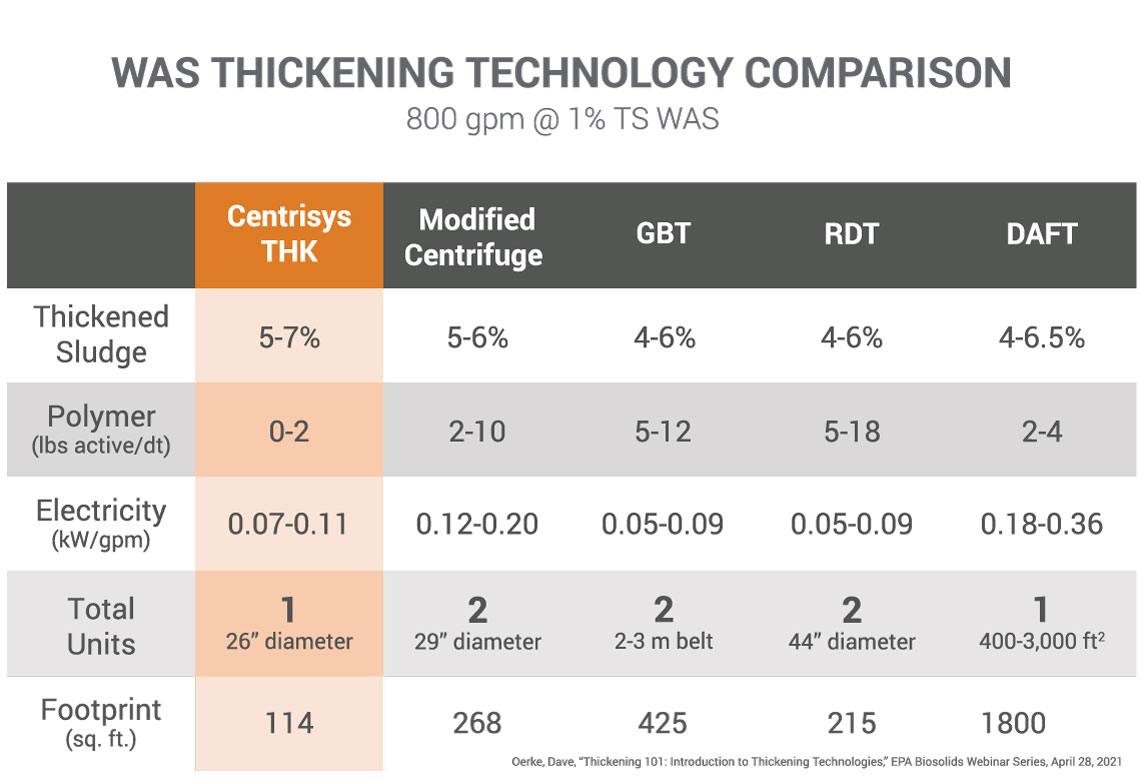

The non-conical design results in greater G-volume, allowing for the highest capacity of flow to the centrifuge for the thickening of sewage sludge at sewage treatment plants. The THK Series Sewage Sludge Thickener improves upon existing technologies using fundamental principles of a 1) Centrifuge - 3,000 Gs, 2) Rotary Drum Thickener - fully enclosed and small footprint, 3) Dissolved Air Flotation (DAFT) - air injection. The patented Hydro-Pneumatic design has proven that NO polymer is required under normal conditions (150 SVI).

- No-Conical = greater comparative capacity

- Proprietary hydro-pneumatic control of cake solids

- Independent control of liquids and solids weir

- Greater G-volume

- Proprietary internal polymer injection system (optional)

- Highest grade materials of construction

- Proprietary tungsten carbide wear plows for grit and trash

- NO polymer required: Calculate your savings

- Proven no polymer required under normal conditions (150 SVI)

- Smallest and most efficient footprint for given flow rates compared to gravity belt and rotary drum thickening technologies

- Contained vapor system

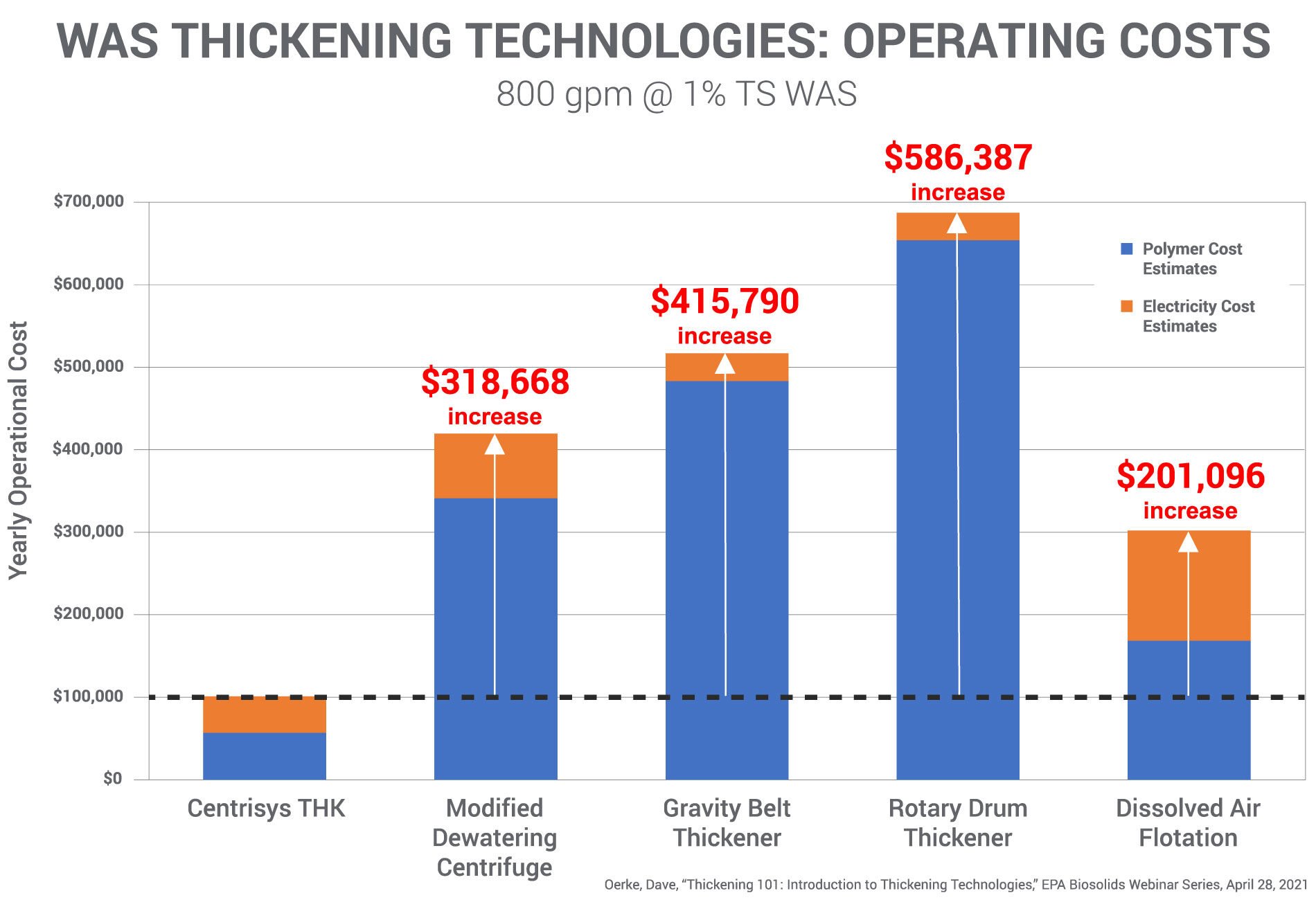

- Expected ROI of 2.5 years due to polymer savings alone

- Reduced operating and maintenance costs

- 50% less power consumption compared to standard dewatering centrifuges

- Reduced installation costs by 35-50% ($/gpm)

- Simple to operate with minimal operator attention

Sludge Thickener THK Series

| THK200 | THK200 | THK350 | THK350 | THK600 | THK600 | |

|---|---|---|---|---|---|---|

| Maximum or Average | Maximum | Average | Maximum | Average | Maximum | Average |

| Feed Flow Rate w/o Polymer* gpm | 180 | 125 | 320 | 265 | 765 | 640 |

| Feed Flow Rate w/ Polymer* gpm | 250 | 200 | 500 | 425 | 1,100 | 800 |

| Approx. Bowl Diameter in (m) | 18 (0.45) |

18 (0.45) |

21 (0.53) |

21 (0.53) |

26 (0.66) |

26 (0.66) |

| Total Static Weight - Empty lbs (kg) | 5,000 (2,950) |

5,000 (2,950) |

10,800 (4,900) |

10,800 (4,900) |

27,000 (12,250) |

27,000 (12,250) |

| Standard Main Drive HP | 50 | 50 | 75 | 75 | 150 | 150 |

| Standard Scroll Drive HP | 10 | 10 | 15 | 15 | 25 | 25 |

| Standard Total Installed HP | 60 | 60 | 90 | 90 | 175 | 175 |

| G-volume Capacity at 3,000 G gal | 160,000 | 160,000 | 332,000 | 332,000 | 718,000 | 718,000 |

| Feed Flow Rate w/o Polymer* gpm | 180 |

| Feed Flow Rate w/ Polymer* gpm | 250 |

| Approx. Bowl Diameter in (m) | 18 (0.45) |

| Total Static Weight - Empty lbs (kg) | 5,000 (2,950) |

| Standard Main Drive HP | 50 |

| Standard Scroll Drive HP | 10 |

| Standard Total Installed HP | 60 |

| G-volume Capacity at 3,000 G gal | 160,000 |

| Feed Flow Rate w/o Polymer* gpm | 125 |

| Feed Flow Rate w/ Polymer* gpm | 200 |

| Approx. Bowl Diameter in (m) | 18 (0.45) |

| Total Static Weight - Empty lbs (kg) | 5,000 (2,950) |

| Standard Main Drive HP | 50 |

| Standard Scroll Drive HP | 10 |

| Standard Total Installed HP | 60 |

| G-volume Capacity at 3,000 G gal | 160,000 |

| Feed Flow Rate w/o Polymer* gpm | 320 |

| Feed Flow Rate w/ Polymer* gpm | 500 |

| Approx. Bowl Diameter in (m) | 21 (0.53) |

| Total Static Weight - Empty lbs (kg) | 10,800 (4,900) |

| Standard Main Drive HP | 75 |

| Standard Scroll Drive HP | 15 |

| Standard Total Installed HP | 90 |

| G-volume Capacity at 3,000 G gal | 332,000 |

| Feed Flow Rate w/o Polymer* gpm | 265 |

| Feed Flow Rate w/ Polymer* gpm | 425 |

| Approx. Bowl Diameter in (m) | 21 (0.53) |

| Total Static Weight - Empty lbs (kg) | 10,800 (4,900) |

| Standard Main Drive HP | 75 |

| Standard Scroll Drive HP | 15 |

| Standard Total Installed HP | 90 |

| G-volume Capacity at 3,000 G gal | 332,000 |

| Feed Flow Rate w/o Polymer* gpm | 765 |

| Feed Flow Rate w/ Polymer* gpm | 1,100 |

| Approx. Bowl Diameter in (m) | 26 (0.66) |

| Total Static Weight - Empty lbs (kg) | 27,000 (12,250) |

| Standard Main Drive HP | 150 |

| Standard Scroll Drive HP | 25 |

| Standard Total Installed HP | 175 |

| G-volume Capacity at 3,000 G gal | 718,000 |

| Feed Flow Rate w/o Polymer* gpm | 640 |

| Feed Flow Rate w/ Polymer* gpm | 800 |

| Approx. Bowl Diameter in (m) | 26 (0.66) |

| Total Static Weight - Empty lbs (kg) | 27,000 (12,250) |

| Standard Main Drive HP | 150 |

| Standard Scroll Drive HP | 25 |

| Standard Total Installed HP | 175 |

| G-volume Capacity at 3,000 G gal | 718,000 |

| Feed Flow Rate w/o Polymer* gpm | 180 |

| Feed Flow Rate w/ Polymer* gpm | 250 |

| Approx. Bowl Diameter in (m) | 18 (0.45) |

| Total Static Weight - Empty lbs (kg) | 5,000 (2,950) |

| Standard Main Drive HP | 50 |

| Standard Scroll Drive HP | 10 |

| Standard Total Installed HP | 60 |

| G-volume Capacity at 3,000 G gal | 160,000 |

| Feed Flow Rate w/o Polymer* gpm | 125 |

| Feed Flow Rate w/ Polymer* gpm | 200 |

| Approx. Bowl Diameter in (m) | 18 (0.45) |

| Total Static Weight - Empty lbs (kg) | 5,000 (2,950) |

| Standard Main Drive HP | 50 |

| Standard Scroll Drive HP | 10 |

| Standard Total Installed HP | 60 |

| G-volume Capacity at 3,000 G gal | 160,000 |

| Feed Flow Rate w/o Polymer* gpm | 320 |

| Feed Flow Rate w/ Polymer* gpm | 500 |

| Approx. Bowl Diameter in (m) | 21 (0.53) |

| Total Static Weight - Empty lbs (kg) | 10,800 (4,900) |

| Standard Main Drive HP | 75 |

| Standard Scroll Drive HP | 15 |

| Standard Total Installed HP | 90 |

| G-volume Capacity at 3,000 G gal | 332,000 |

| Feed Flow Rate w/o Polymer* gpm | 265 |

| Feed Flow Rate w/ Polymer* gpm | 425 |

| Approx. Bowl Diameter in (m) | 21 (0.53) |

| Total Static Weight - Empty lbs (kg) | 10,800 (4,900) |

| Standard Main Drive HP | 75 |

| Standard Scroll Drive HP | 15 |

| Standard Total Installed HP | 90 |

| G-volume Capacity at 3,000 G gal | 332,000 |

| Feed Flow Rate w/o Polymer* gpm | 765 |

| Feed Flow Rate w/ Polymer* gpm | 1,100 |

| Approx. Bowl Diameter in (m) | 26 (0.66) |

| Total Static Weight - Empty lbs (kg) | 27,000 (12,250) |

| Standard Main Drive HP | 150 |

| Standard Scroll Drive HP | 25 |

| Standard Total Installed HP | 175 |

| G-volume Capacity at 3,000 G gal | 718,000 |

| Feed Flow Rate w/o Polymer* gpm | 640 |

| Feed Flow Rate w/ Polymer* gpm | 800 |

| Approx. Bowl Diameter in (m) | 26 (0.66) |

| Total Static Weight - Empty lbs (kg) | 27,000 (12,250) |

| Standard Main Drive HP | 150 |

| Standard Scroll Drive HP | 25 |

| Standard Total Installed HP | 175 |

| G-volume Capacity at 3,000 G gal | 718,000 |

Literature

- Sludge Reduction Technologies for Plants of All Sizes

- Kenosha Water Utility Energy Optimization Resource Recovery Project

- Centrisys Achieves Improved Performance and Reliability with THK Sludge Thickening Centrifuges

- Sharjah Municipality Drainage Department Flow Chart

- Get More from your Centrifuge

- 9 Reasons to Choose Centrisys

- The Centrisys-Viscotherm Scroll Drive is the Most Efficient in the Centrifuge Industry

- Complete Self-Contained Mobile Trailer Systems

- High Performance Skid Systems

- Centrisys THK Sludge Thickener Lease+ Program

- The Lowest Total Cost of Ownership in the Industry

- CSI: A 40+ Point Centrifuge Inspection Program

- Direct Replacement for 3-Stage Planetary Gearbox on the Derrick 7200 Centrifuge

- Decanter Centrifuge Parts Available When You Need Them

- Urgent Centrifuge Repair Response, Because You Can't Afford to Wait

- Enhance Performance and Extend the Life of your Decanter Centrifuge

Case Studies

- Plant Replaces Aging DAFs with Sludge Thickening Centrifuges

- Plant Replaces Modified Dewatering Centrifuges with Sludge Thickening Centrifuges

- Plant Uses Sludge Thickening Centrifuge to Eliminate 50% Transportation Surcharge

- Plant Uses Sludge Thickening Centrifuge to Thicken WAS Before Digestion

- UAE Plant Replaces Aging GBTs with Sludge Thickening Centrifuges

Videos

General Arrangements

✕