PONDUS: A Simple Solution for Thermal Hydrolysis

Quick Links

Keep the Thermal Hydrolysis Process Simple, Affordable, Safe for All Sized Plants

As a Cost-Effective Choice, PONDUS™ Requires Little Day-To-Day Plant Supervision

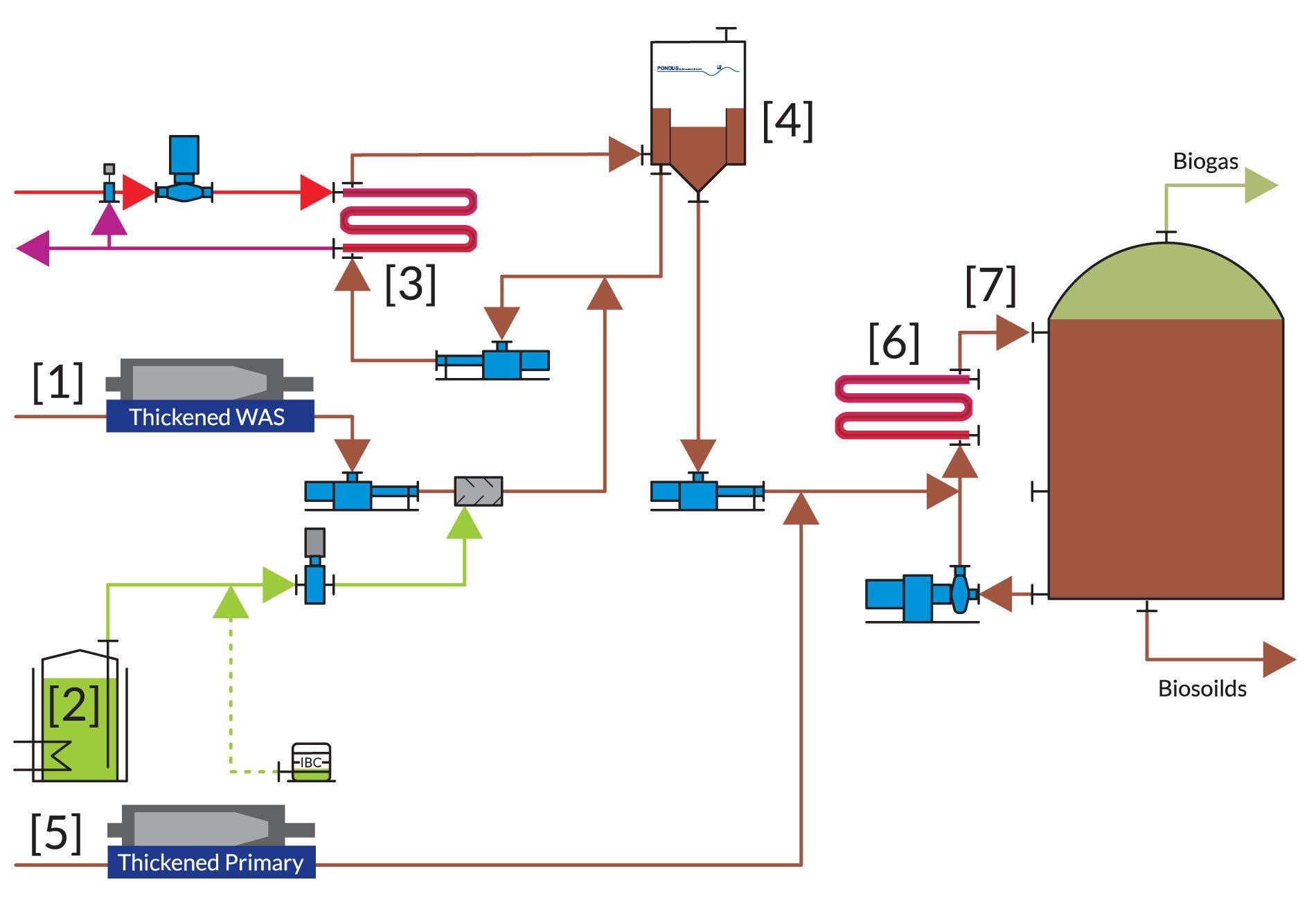

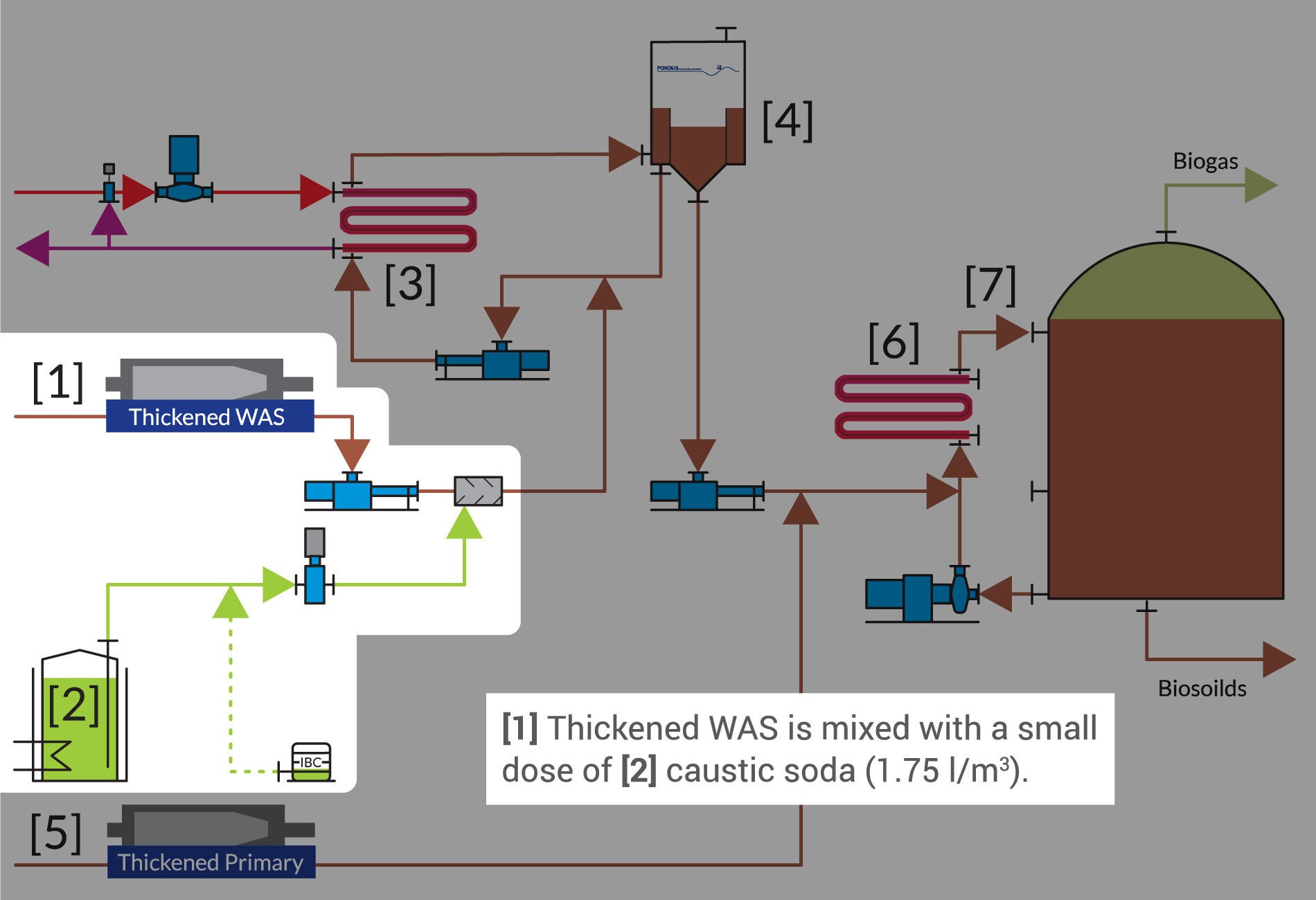

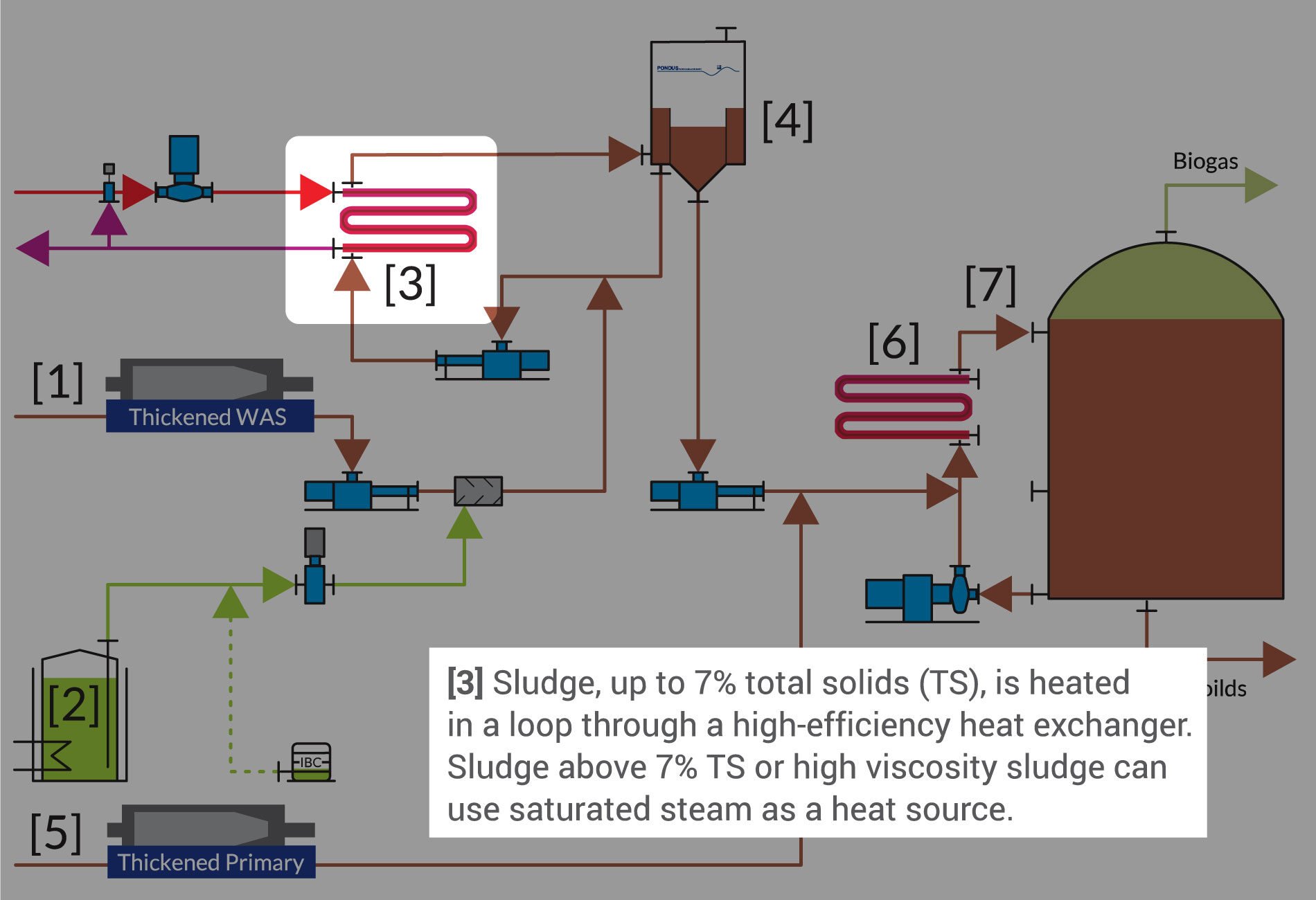

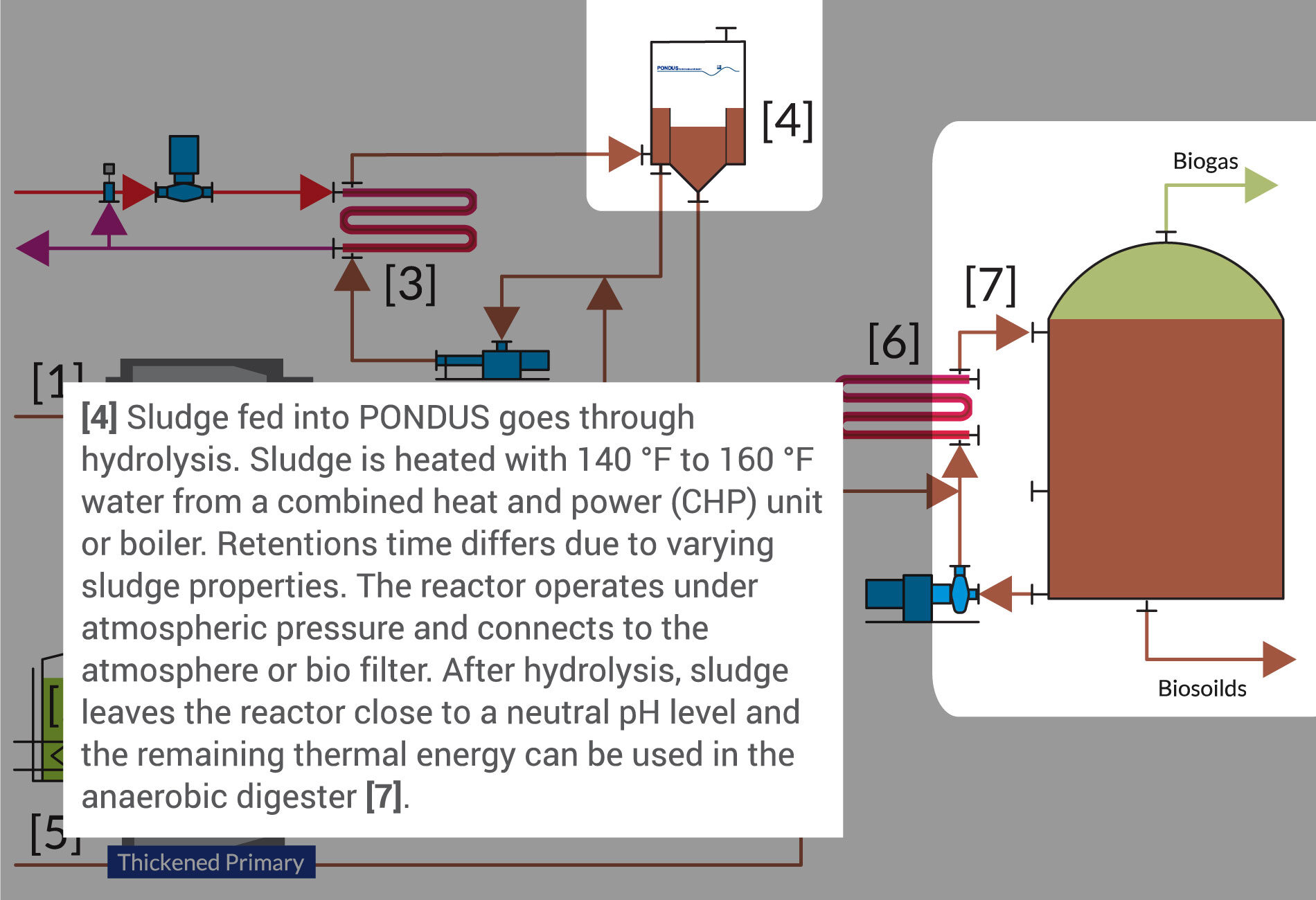

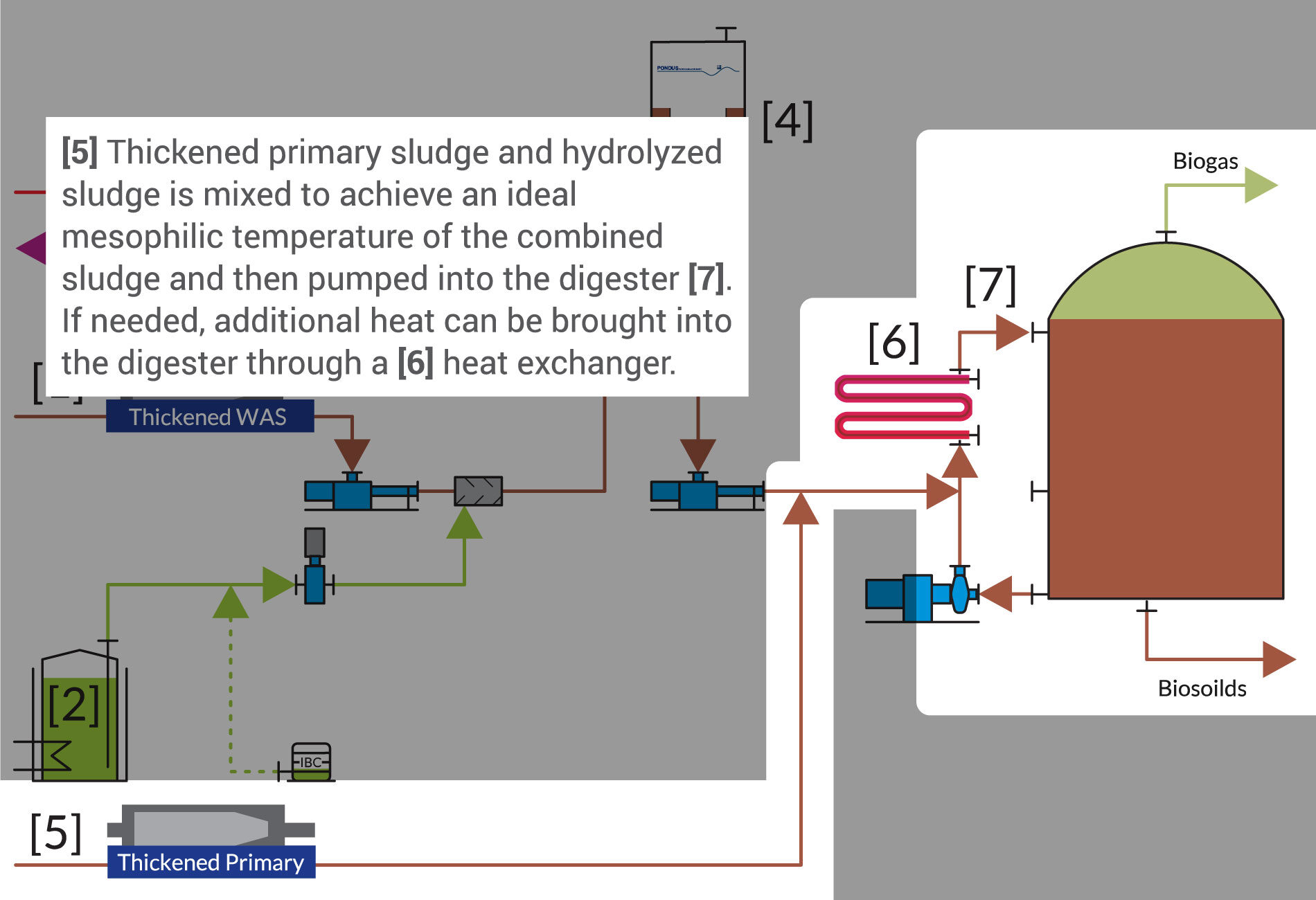

PONDUS, a thermal/alkaline hydrolysis process, is designed for solids from 4% to 12% and uses a combination of caustic soda (NaOH) and low grade heated water (140 °F to 160 °F) to break down the cell walls.

The passing of the Inflation Reduction Act in late 2022 is a great incentive for facilities to install a biogas process like PONDUS and take advantage of the new Investment Tax Credit (ITC).

Awards Won:

- 2019 Frost & Sullivan Product Leadership Award for the North American Sludge Treatment

- 2018 Utility of the Future Today Recognition Program for the Kenosha WWTP Optimization Project

- 2017 W&WD Top Project for the Kenosha WWTP Optimization Project

- 2017 ACEC Grand Award Winner for the Kenosha WWTP Optimization Project

- Reduce Viscosity of Thickened WAS up to 80%

- Reduce Anaerobic Digestion Volume up to 50%

- Reduce Biosolids Disposal Costs up to 30%

- Increase Biogas Production up to 35%

- Reduce Polymer Consumption at Dewatering up to 20%

- Reduce Digester Foaming

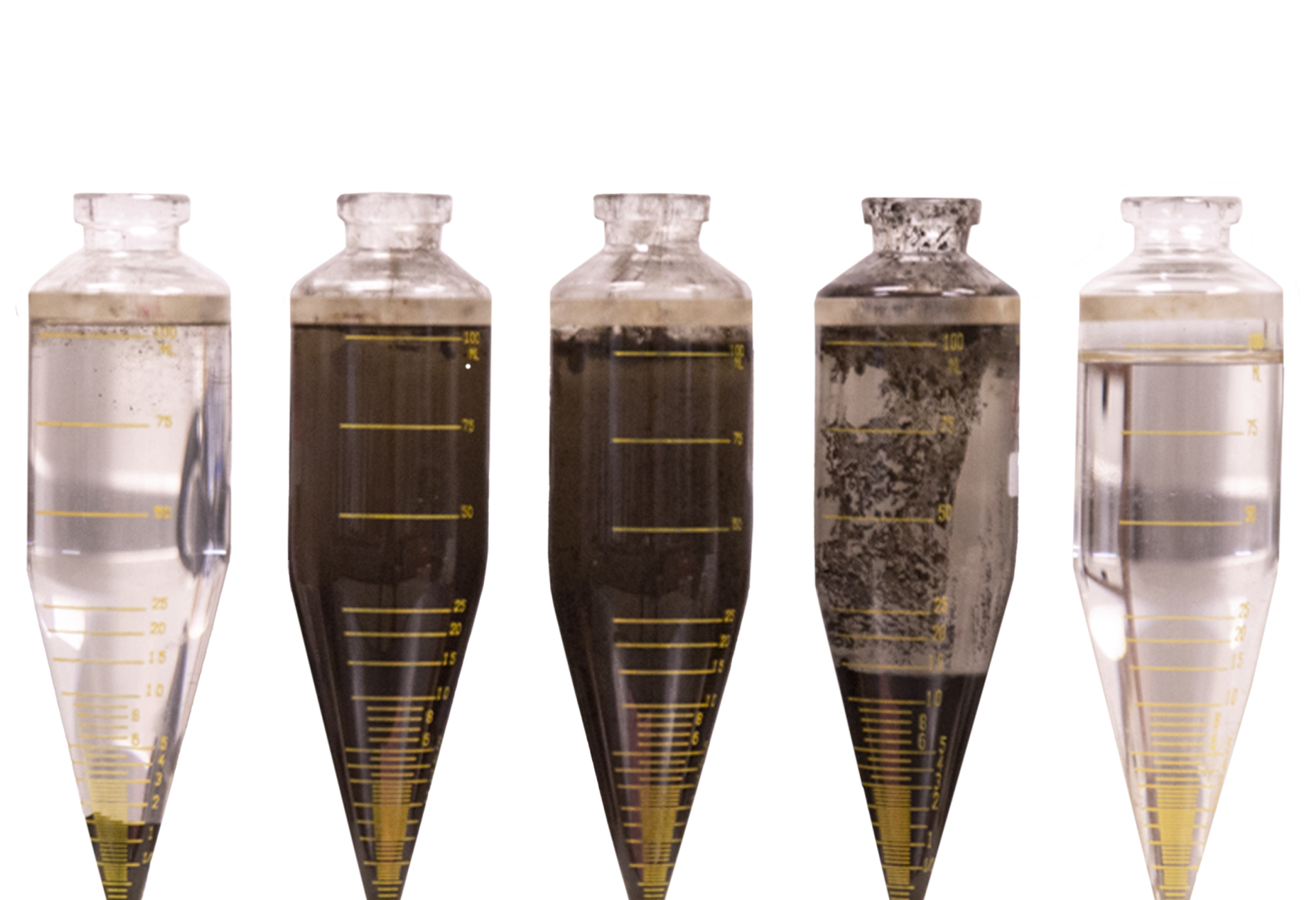

Request a Sample Analysis or Pilot Test

PONDUS is Simple to Operate

Compact, small footprint solution for all sized plants.

- Hydrolysis reactor operating under atmospheric pressure

- High-efficiency hot water heat exchanger

- Chemical dosing station

- Progressive cavity pumps

- Instrumentation and controls

Saturated steam option for sludge above 7% total solids (TS) or with high viscosity.

Typical maintenance includes:

- Pump maintenance

- Heat exchanger cleaning

✕

PONDUS is a Cost-Effective Choice

- Simple operation requires little day-to-day plant supervision

- Fully automatic process runs 24/7 year-round

- 99% uptime; minimal estimated downtime for maintenance and repairs

- Designed using standard industrial control system equipment

- Compact; small footprint solution for all sized plants

Literature

Case Studies

Videos

✕