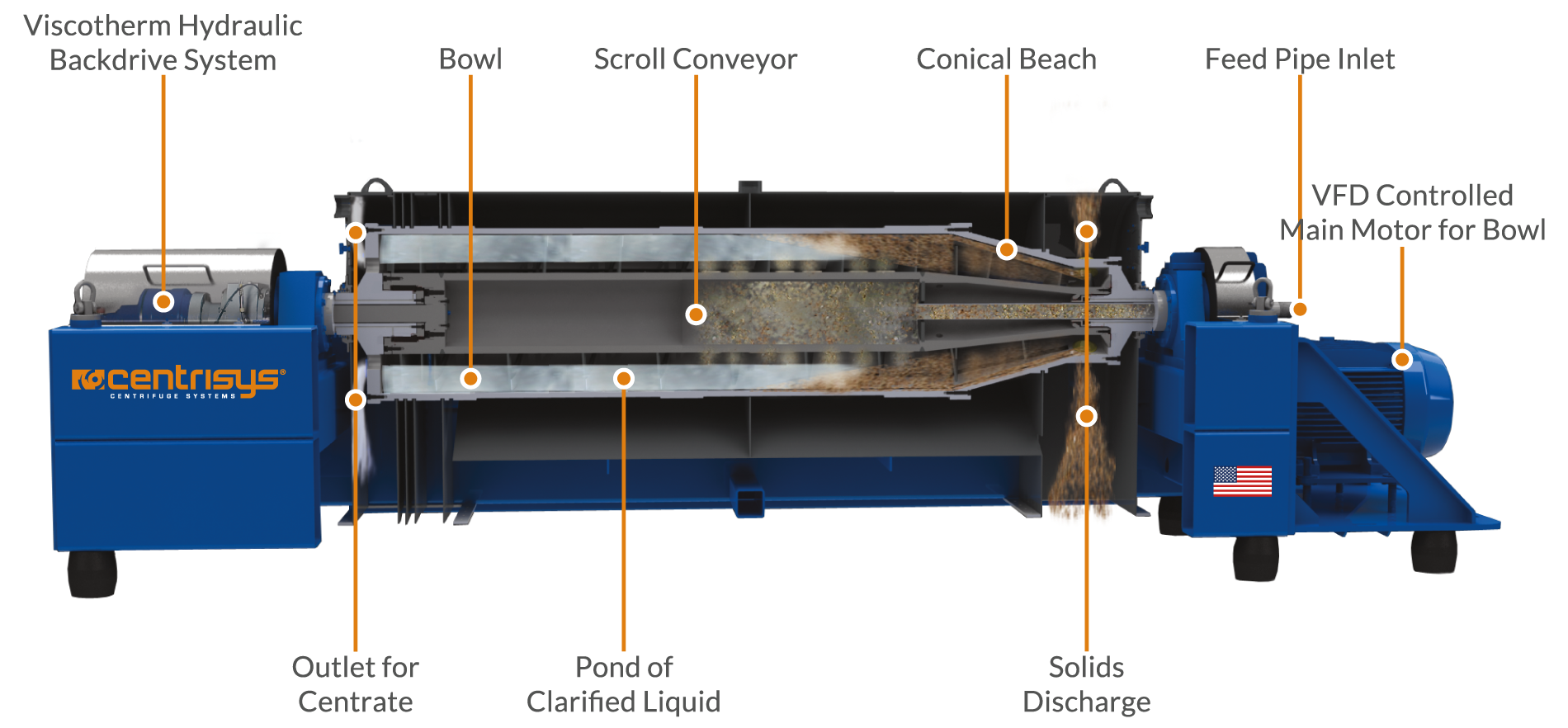

Decanter Centrifuge

CS Series for Sludge Dewatering

A Decanter Centrifuge for the Management of Wastewater, Sewage Sludge, and Industrial Liquid and Solids Separation

In 1987, Centrisys designed and built its first centrifuge around what was learned in the field by servicing competitor’s equipment in both municipal and industrial applications. Thirty years later, the Centrisys engineering team continues to benefit from problem-solving, learning what does and does not work in the real world and takes that knowledge to continue Centrisys’ lifelong commitment to brand excellence. By providing the most efficient, robust decanter centrifuges, Centrisys gives our customers the results they need. Learn about how Centrisys/CNP is USA BABA manufacturing compliant.

- The Rotodiff® hydraulic scroll drive—our standard

backdrive technology from day one - Highest G-volume and torque capacity

- Increase solids handling

- Reduce polymer consumption

- Continuous operation

- Lowest installed horsepower

- Driest cake

- Customizable for unique application requirements

- Lowest measured energy consumption*

- Reduce operating and maintenance costs

- Reduce disposal costs

- Highest torque to weight ratio

- ISO 9001:2015 and manufactured in Wisconsin

USA Engineered and Manufactured

Centrisys-Viscotherm Scroll Drive

Highest Quality

Advanced Wear Protection

Scroll Design and Development

Centrifuge Energy Recovery System

USA Engineered and Manufactured

Centrisys-Viscotherm Scroll Drive

The most efficient in the industry with a simplified design; highest torque to weight ratio with the best process control.

Highest Quality

Advanced Wear Protection

Scroll Design and Development

Centrifuge Energy Recovery System

Dewatering Decanter Centrifuges - CS Series

| CS6-4 | CS10-4 | CS14-4 | CS18-4 | CS18-4HC | CS21-4 | CS21-4HC | CS26-4EV | CS26-4 | CS30-4 | CS44-4 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Phase | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2 |

| Feed Capacity* gpm (m3h) | 2-10 (0.5-2) |

5-35 (1-8) |

20-60 (5-14) |

50-100 (11-23) |

75-125 (17-29) |

100-175 (23-40) |

150-225 (34-51) |

150-320 (34-73) |

200-400 (45-90) |

300-700 (68-159) |

500-1,000 (114-227) |

| Weight lbs (kgs) | 700 (318) |

2,000 (910) |

3,800 (1,725) |

6,500 (2,950) |

8,200 (3,720) |

8,500 (3,860) |

10,000 (4,550) |

16,500 (7,490) |

18,500 (8,400) |

30,000 (13,600) |

50,000 (22,680) |

| Total Installed Power HP (kW) | 8 (6) |

20 (15) |

40 (30) |

50 (38) |

60 (45) |

75 (56) |

90 (68) |

140 (105) |

165 (123) |

275 (205) |

450 (336) |

| Avail. Shallow Pool/Angle | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES |

| Auto Lube System | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES |

| L x W x H in (m) | 75x21x28 (1.9x0.5x0.7) |

89x44x27 (2.3x1.1x7) |

122x34x31 (3.1x0.9x0.8) |

151x44x41 (3.8x1.1x1) |

175x44x47 (4.5x1.1x1.2) |

175x44x47 (4.5x1.1x1.2) |

190x45x53 (4.8x1.2x1.4) |

210x56x62 (5.3x1.4x1.6) |

225x56x62 (5.7x1.4x1.6) |

258x74x75 (6.6x1.9x1.9) |

248x122x70 (5.2x3.1x1.8) |

| Cake Dryness | Up to 40% process dependant | Up to 40% process dependant | Up to 40% process dependant | Up to 40% process dependant | Up to 40% process dependant | Up to 40% process dependant | Up to 40% process dependant | Up to 40% process dependant | Up to 40% process dependant | Up to 40% process dependant | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 2-10 (0.5-2) |

| Weight lbs (kgs) | 700 (318) |

| Total Installed Power HP (kW) | 8 (6) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 75x21x28 (1.9x0.5x0.7) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 5-35 (1-8) |

| Weight lbs (kgs) | 2,000 (910) |

| Total Installed Power HP (kW) | 20 (15) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 89x44x27 (2.3x1.1x7) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 20-60 (5-14) |

| Weight lbs (kgs) | 3,800 (1,725) |

| Total Installed Power HP (kW) | 40 (30) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 122x34x31 (3.1x0.9x0.8) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 50-100 (11-23) |

| Weight lbs (kgs) | 6,500 (2,950) |

| Total Installed Power HP (kW) | 50 (38) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 151x44x41 (3.8x1.1x1) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 75-125 (17-29) |

| Weight lbs (kgs) | 8,200 (3,720) |

| Total Installed Power HP (kW) | 60 (45) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 175x44x47 (4.5x1.1x1.2) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 100-175 (23-40) |

| Weight lbs (kgs) | 8,500 (3,860) |

| Total Installed Power HP (kW) | 75 (56) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 175x44x47 (4.5x1.1x1.2) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 150-225 (34-51) |

| Weight lbs (kgs) | 10,000 (4,550) |

| Total Installed Power HP (kW) | 90 (68) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 190x45x53 (4.8x1.2x1.4) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 150-320 (34-73) |

| Weight lbs (kgs) | 16,500 (7,490) |

| Total Installed Power HP (kW) | 140 (105) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 210x56x62 (5.3x1.4x1.6) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 200-400 (45-90) |

| Weight lbs (kgs) | 18,500 (8,400) |

| Total Installed Power HP (kW) | 165 (123) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 225x56x62 (5.7x1.4x1.6) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 300-700 (68-159) |

| Weight lbs (kgs) | 30,000 (13,600) |

| Total Installed Power HP (kW) | 275 (205) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 258x74x75 (6.6x1.9x1.9) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2 |

| Feed Capacity* gpm (m3h) | 500-1,000 (114-227) |

| Weight lbs (kgs) | 50,000 (22,680) |

| Total Installed Power HP (kW) | 450 (336) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 248x122x70 (5.2x3.1x1.8) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 2-10 (0.5-2) |

| Weight lbs (kgs) | 700 (318) |

| Total Installed Power HP (kW) | 8 (6) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 75x21x28 (1.9x0.5x0.7) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 5-35 (1-8) |

| Weight lbs (kgs) | 2,000 (910) |

| Total Installed Power HP (kW) | 20 (15) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 89x44x27 (2.3x1.1x7) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 20-60 (5-14) |

| Weight lbs (kgs) | 3,800 (1,725) |

| Total Installed Power HP (kW) | 40 (30) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 122x34x31 (3.1x0.9x0.8) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 50-100 (11-23) |

| Weight lbs (kgs) | 6,500 (2,950) |

| Total Installed Power HP (kW) | 50 (38) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 151x44x41 (3.8x1.1x1) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 75-125 (17-29) |

| Weight lbs (kgs) | 8,200 (3,720) |

| Total Installed Power HP (kW) | 60 (45) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 175x44x47 (4.5x1.1x1.2) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 100-175 (23-40) |

| Weight lbs (kgs) | 8,500 (3,860) |

| Total Installed Power HP (kW) | 75 (56) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 175x44x47 (4.5x1.1x1.2) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 150-225 (34-51) |

| Weight lbs (kgs) | 10,000 (4,550) |

| Total Installed Power HP (kW) | 90 (68) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 190x45x53 (4.8x1.2x1.4) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 150-320 (34-73) |

| Weight lbs (kgs) | 16,500 (7,490) |

| Total Installed Power HP (kW) | 140 (105) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 210x56x62 (5.3x1.4x1.6) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 200-400 (45-90) |

| Weight lbs (kgs) | 18,500 (8,400) |

| Total Installed Power HP (kW) | 165 (123) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 225x56x62 (5.7x1.4x1.6) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2/3 |

| Feed Capacity* gpm (m3h) | 300-700 (68-159) |

| Weight lbs (kgs) | 30,000 (13,600) |

| Total Installed Power HP (kW) | 275 (205) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 258x74x75 (6.6x1.9x1.9) |

| Cake Dryness | Up to 40% process dependant |

| Phase | 2 |

| Feed Capacity* gpm (m3h) | 500-1,000 (114-227) |

| Weight lbs (kgs) | 50,000 (22,680) |

| Total Installed Power HP (kW) | 450 (336) |

| Avail. Shallow Pool/Angle | YES |

| Auto Lube System | YES |

| L x W x H in (m) | 248x122x70 (5.2x3.1x1.8) |

| Cake Dryness | Up to 40% process dependant |

DT Series

The Centrisys innovative DT Model Decanter Centrifuge is the first decanter centrifuge developed specifically for the manure industry and is the proven solution to do more with manure management to ensure profitability and achieve environmental goals.

- Haul less by concentrating nutrients to manure solids

- Help producers meet nutrient removal permit requirements

- Reduce storage lagoon dredging frequency

- Minimize water use by recycling manure liquid

T Series

The Centrisys T Model Decanter Centrifuge increases solids loading capacity, supports on-the-fly bowl changes and features higher quality centrifugally cast components that meet

ISO 9001:2015 standards.

- Process 20 pounds per gallon of weighted mud or flocculated ultra-fine slurries

- A890 duplex stainless steel for bowl longevity in low pH environments, higher tensile strength and greater corrosion resistance compared to 316SS

- Feed and solids discharge with replaceable tungsten carbon tiles

Literature

- Sludge Reduction Technologies for Plants of All Sizes

- Kenosha Water Utility Energy Optimization Resource Recovery Project

- Why New York City Chose Centrisys

- Get More from your Centrifuge

- 9 Reasons to Choose Centrisys

- The Centrisys-Viscotherm Scroll Drive is the Most Efficient in the Centrifuge Industry

- Energy-Efficient 3-Phase Separation

- The Right Dewatering Solution, the Fastest Payback, Lowest Cost of Ownership

- Complete Self-Contained Mobile Trailer Systems

- High Performance Skid Systems

- Recover Resouces. Uncover Revenue.

- Partnership Put DT Model Decanter Centrifuges to Work in Manure Management

- Enhance Environmental Performance

- Designed and Built for Improved Profitability

- Achieve Higher Clarification Using Less Power

- CSI: A 40+ Point Centrifuge Inspection Program

- Direct Replacement for 3-Stage Planetary Gearbox on the Derrick 7200 Centrifuge

- Decanter Centrifuge Parts Available When You Need Them

- Urgent Centrifuge Repair Response, Because You Can't Afford to Wait

- Enhance Performance and Extend the Life of your Decanter Centrifuge

Case Studies

- City Reduces Disposal Costs by Replacing Belt Filter Presses with CS26-4 Dewatering Centrifuges

- Manure Handling System Needed to Recycle Most of the Manure for Flushing

- Reduce Lagoon Dredging at a Dairy Farm with a CS26-4DT Centrifuge

- Reduce Lagoon Solids and Phosphorus with CS21-4DT Decanter Centrifuge

Videos

General Arrangements

- CS30-4T 2-Phase Decanter Centrifuge

- CS26-4DT 2-Phase Decanter Centrifuge

- CS21-4HC DT 2-Phase Decanter Centrifuge

- CS21-4T 2-Phase Decanter Centrifuge

- CS21-4HC 2-Phase Decanter Centrifuge

- CS18-3 2-Phase Decanter Centrifuge

- CS26-4EV 2-Phase Decanter Centrifuge

- CS26-4 2-Phase Decanter Centrifuge

- CS21-4 2-Phase Decanter Centrifuge

- CS18-4 2-Phase Decanter Centrifuge

- CS30-4 2-Phase Decanter Centrifuge

- CS18-4 3-Phase Decanter Centrifuge

- CS21-4 3-Phase Decanter Centrifuge

- CS14-4 3-Phase Decanter Centrifuge

- CS14-4 2-Phase Decanter Centrifuge

- CS10-4 3-Phase Decanter Centrifuge