PILOT DEMONSTRATION:

Soap and Fiber Separation

Quick Links

Optimizing Soap and Fiber Recovery at Pulp and Paper Mills

The pilot program's primary aim was to demonstrate the enhanced efficiency of soap and fiber extraction from black liquor using Centrisys Renewables Decanter Centrifuge Technology (DCT) at a kraft pulp mill. Traditional black liquor soap skimmers are older technology and, in most cases, have not been upgraded in years. The DCT technology leverages a sophisticated three-phase decanter centrifuge, designed to optimize the separation processes and improve operational stability.

The DCT System incorporates a high-grade CS21-4HC 3-phase skid-mounted decanter centrifuge, forming part of a comprehensive skid assembly. This assembly is meticulously designed, featuring a separator, a valve module equipped with essential components for optimal routing, and an advanced electrical control panel that includes a 480 v breaker and a Programmable Logic Controller (PLC). The system is also equipped with specialized pumps for managing inlet and outlet flows, ensuring efficient process management.

Operational Integration

Seamlessly integrated with the mill’s existing soap skimming processes, the DCT System enhances operational efficiency without disrupting ongoing operations.

Performance Validation

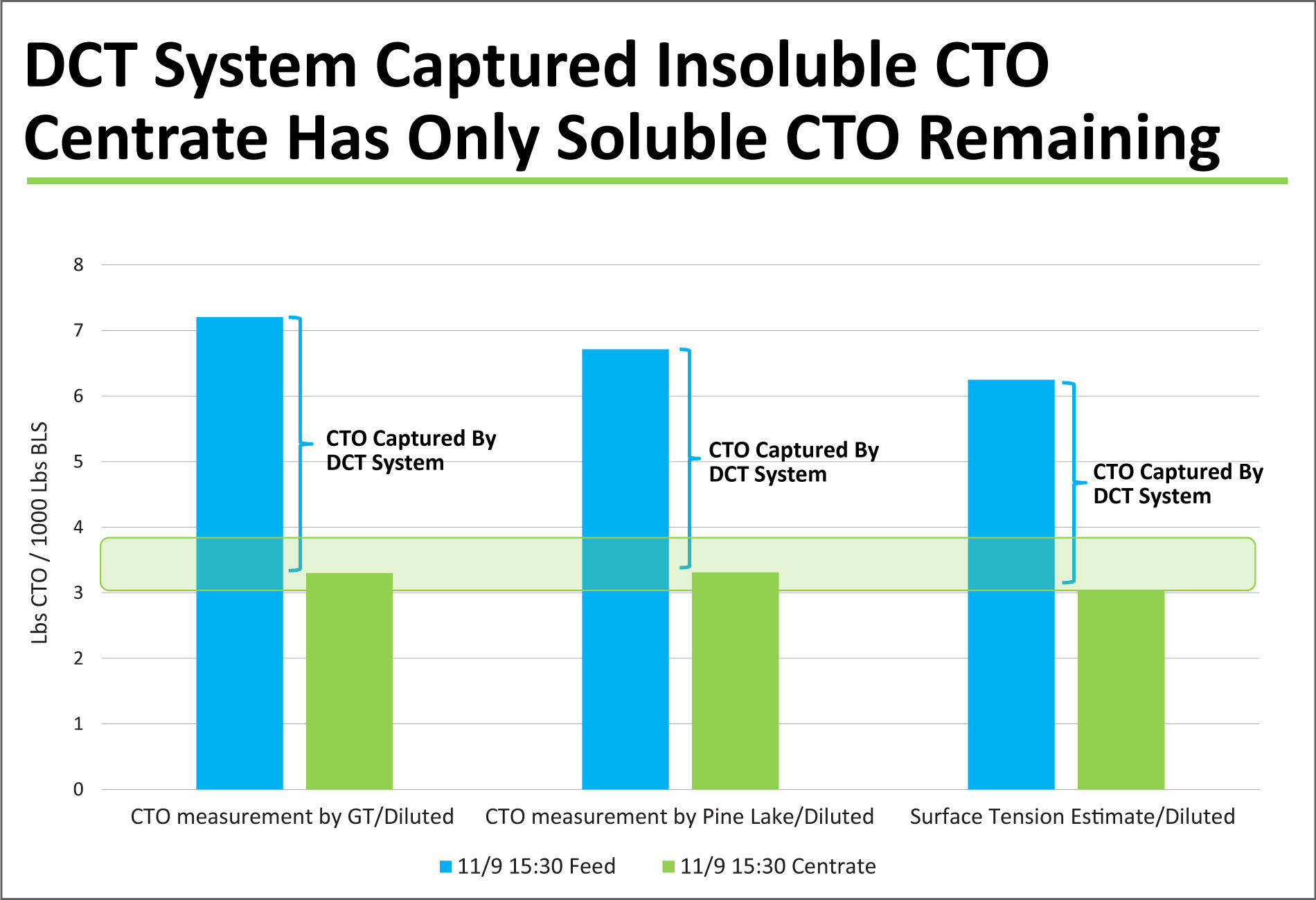

To ensure reliability, performance samples were collected at regular intervals and analyzed using a dual-method approach in three distinct laboratories. The analytical results confirmed the high efficiency of the proprietary DCT System, highlighting its capability to:

- Achieve complete separation of insoluble soap and fiber from black liquor

- Produce a centrate containing black liquor with only solubilized soap

- Remove fluctuating levels of fibers effectively, thereby validating the system's processing efficacy

- Maintain continuous operation, thereby eliminating downtime and boosting productivity

Implementing the DCT technology offers several advantages:

- Potential elimination or substantial improvement over traditional soap skimming methods

- Increased soap recovery rates, reducing mill operating cost by boosting the mill’s Crude Tall Oil (CTO) revenue

- Enhanced processing capacity for softwoods without additional skimmer capacity requirements

- Efficient fiber removal, DCT can smoothly handle fiber surges

- Recovery boiler limitations alleviated

- Reduced frequency and severity of maintenance on evaporators

- Compact design, offering flexibility in installation and minimizing space requirements

The integration of Centrisys Renewables Decanter Centrifuge Technology (DCT) streamlines the recovery of black liquor soap and fiber and also aligns with sustainability goals of modern pulp & paper mills by enhancing efficiency and reducing waste. The DCT system is fully customizable and available in different sizes and metallurgies.

Interested in more?