Decanter Centrifuge Retrofit + Upgrade Options

Enhance Decanter Centrifuge Performance When You Retrofit and Upgrade

Upgrade for Extended, Optimal Performance

Get the most out of your centrifuge with a retrofit from Centrisys. Save on maintenance and energy costs while increasing uptime, performance, life expectancy, and efficiency when you replace your old gearbox drive with a Viscotherm Hydraulic Scroll Drive.

Do you have a new centrifuge where performance is limited by torque or an older machine that needs to keep running but is not delivering the performance needed? Upgrading your centrifuge with a state-of-the art Viscotherm Hydraulic Scroll Drive will save on long-term expenses and improve the performance of your process. Centrisys has experience with service and repair with these gearbox drives:

- Planetary - from 2 to multiple stages

- Cyclo-Gear

- Simp-Drive®

Backdrive Controllers:

- Eddy Current

- DC Motors

- AC Motors

One of the largest food processors in the U.S. reached its ROI in just two years when upgrading 50 centrifuges with a Viscotherm Hydraulic Scroll Drive. Call us to determine if a retrofit or an upgrade is an option for your centrifuge.

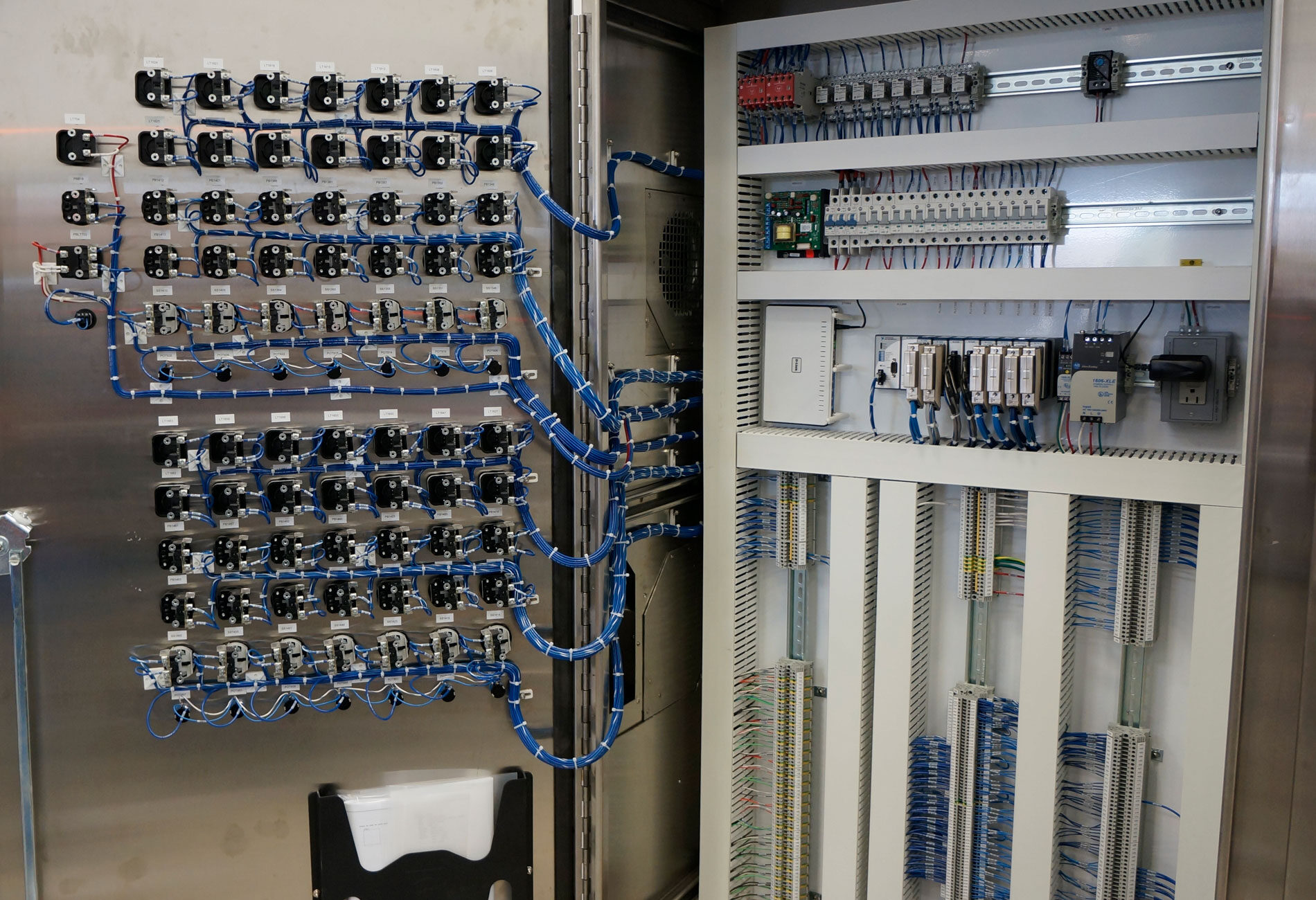

Control Panel Upgrades

Centrisys offers upgrades, retrofits and replacements for all control panels. We upgrade control panels to SCADA Systems and VFD controlled main motors, allowing for easier system monitoring, power savings and efficient operational speeds. Also available for use in Class1/Div1 or Class1/Div2 hazardous environments. Replacing outdated control systems with the latest PLC technology will extend the life of your centrifuge and improve the dewatering process.

Benefits of Going Retro with Centrisys

With our years of experience in servicing and repairing all makes and models of centrifuge equipment, we will help you maximize your investment. A centrifuge retrofit or upgrade with Centrisys offers:

- Improved torque: Get dryer cake and save on hauling costs

- Control panel upgrades: Replace with new, state-of-the-art features

- Reduced maintenance: Make equipment run better and last longer

- Higher temperature tolerance: Hydraulic backdrive oil continuously cools and filters unlike most gearbox based backdrives

- Less downtime: Reduce breakdowns caused by torque or backdrive issues and increase performance over the lifespan of your equipment

- Decrease power usage: Use less energy to operate

When it Comes to Backdrives, Bigger is Definitely NOT Better

The simple, compact, lightweight design is easier to install and fits nicely into your current operations. Despite the smaller size and weight, Viscotherm Hydraulic Scroll Drives with Rotodiff® technology outperforms gear box drives in every way.

Literature

- CSI: A 40+ Point Centrifuge Inspection Program

- Direct Replacement for 3-Stage Planetary Gearbox on the Derrick 7200 Centrifuge

- Decanter Centrifuge Parts Available When You Need Them

- Urgent Centrifuge Repair Response, Because You Can't Afford to Wait

- Enhance Performance and Extend the Life of your Decanter Centrifuge

Videos

Need an Urgent Repair? Contact Centrisys/CNP Now

Service That Never Stops — Nationwide and Global. Centrisys/CNP is always ready to repair, maintain, and optimize any decanter centrifuge make, model, or brand. Our expert technicians are available 24/7, wherever you are. Don’t wait — contact us now for urgent repairs.