Plant Uses Sludge Thickening Centrifuge to Eliminate 50% Transportation Surcharge

Location: University of Florida | Gainesville, Florida

Plant Size: 3.1 MGD

Installation: 2018 (1) THK200 Sludge Thickener

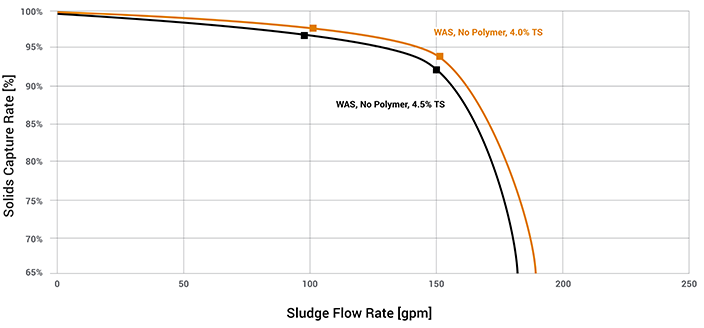

- Feed @ 1.1% TS

- 100 gpm

- 97% capture

- No polymer

- 0.1 kW/gpm

- 3.8-4.2% TS TWAS

PROBLEM

University of Florida’s Water Reclamation Facility gravity thickened WAS to 2% TS and then trucked the TWAS off-site. The plant could not exceed 4.5% TS TWAS or a 50% transportation surcharge was added to the transportation fees. The Centrisys THK reliably doubled the TWAS concentration.

RESULTS

- TWAS concentration doubled from 2% to 4%; resulted in half the truckload amounts

- Eliminated the 50% transportation surcharge

- Maintained a narrow 3.8-4.2% TS TWAS

- Adjustable nozzles and the hydro-pneumatic air adjustment controls allowed consistent output even with seasonal fluctuation

- No polymer used

- Eliminated need for an installed dosing system

- Minimal operator supervision

- High recovery reduced the downstream of the sand filters