Plant Uses Sludge Thickening Centrifuge to Thicken WAS Before Digestion

Location: Whitewater Wastewater Treatment Plant | Whitewater, Wisconsin

Plant Size: 3.65 MGD

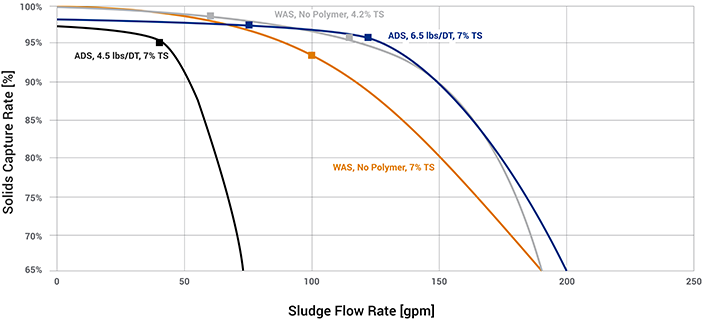

Installation: 2017 (1) THK200 Sludge Thickener

- Feed @ 0.4-0.7% TS

- 60 gpm

- 95% capture

- No polymer

- 0.08-0.12 kW/gpm

- 4-5% TS TWAS

- 5-6% TS ADS

PROBLEM

The wastewater utility land applied anaerobically digested sludge (ADS) and did not have an existing sludge thickening solution. The plant changed from rotating biological contactors (RBC) to an activated sludge system to operate a biological nutrient removal (BNR) process. The most cost-effective and reliable solution was to thicken the WAS before digestion because of the low concentration.

RESULTS

- Installed THK had a dual purpose to reduce volume

- THK thickened the WAS before entering the digester

- After digestion, the same THK thickened the sludge again before land application

- Increased digester capacity and reduced the heat necessary to maintain the digester temperature

- No polymer used for WAS thickening

- Preprogramming the waste amount into the THK eased the operation; THK shuts off when it meets the target wasting

- Operator inputs target number of WAS gallons per day

- THK shuts off when flow meets the quota

- Post-digestion ADS thickening maintained 5-6% TS for land application