DECANTER CENTRIFUGE TECHNOLOGY - DCT

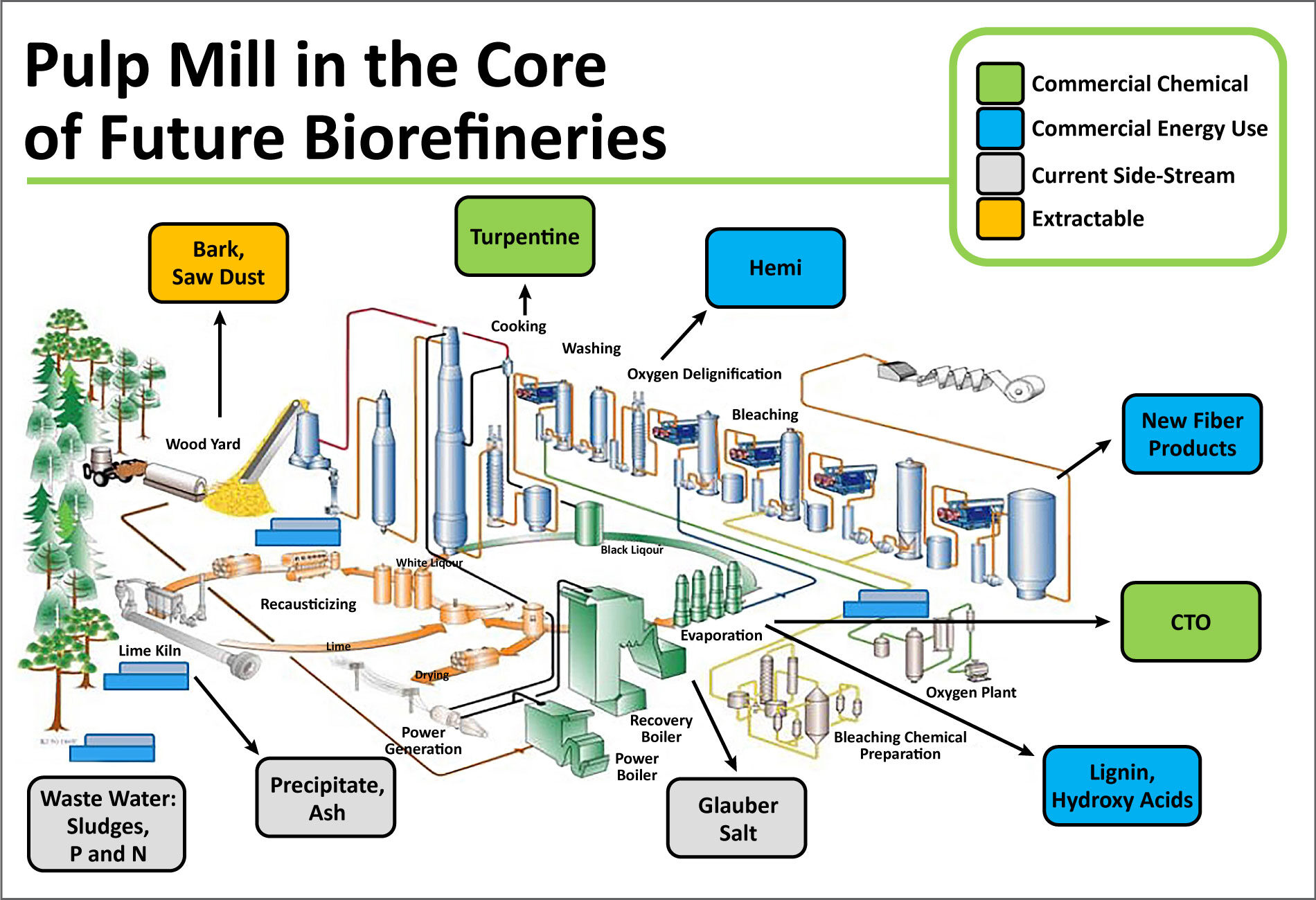

Innovative Technology Solutions to Optimize Pulp & Paper Mill Operations

Decanter Centrifuge Technology (DCT) can significantly improve mill efficiency. Our proprietary technology can be custom engineered to provide two or three phase solutions, such as:

- Soap separation from black liquor

- Fiber removal from black liquor

- Lignin removal from black liquor

- Clean-up of soap, CTO, green liquor, wastewater

DCT is designed and manufactured in the USA, is reliable, low maintenance, has a small footprint (no need to redesign the mill or scale up for additional equipment), is energy efficient, and offers a range of higher throughputs.

Soap and CTO (Crude Tall Oil)

Eliminate or improve skimmers, enhance soap recovery, separate solids from CTO, and potentially increase pulp production.

- Eliminate or improve traditional soap skimmers

- Improve soap recovery and increase CTO revenues

- Separate solids, brine, and black liquor form CTO

- Replace fiber vibration screens prior to CTO cleanup

- Increase pulp production for recovery boiler limited mills

- Increase softwood without adding skimmer capacity

- Reduce fouling and other contamination of evaporators

- Reducing downtime and maintenance

- Small footprint as a standalone system or can run in parallel to soap skimmer for improved skimmers efficiency

- Maintenance package and performance guarantee included

- Manufactured and serviced in USA for over 37 years

Fiber and Solids

Efficiently remove fibers from black liquor (recovered fibers), dewater and thicken materials, eliminate clarifiers, and significantly reduce waste disposal costs.

- Efficiently separate fiber from black liquor – can handle fiber surges.

- Robust and cost-effective dewatering and thickening solutions.

- Can eliminate need for green liquor clarifiers and efficiently separate dregs.

- Significantly reduces landfill and transportation costs by dewatering.

- Streamline operations by eliminating clarifiers and Geotubes®

- Low operational, service, energy, and maintenance costs

- Environmentally friendly and significant cost savings by reducing landfill volumes (50% less water) and dredging/transportation costs.

- More process flexibility

Lignin

Our turn-key solution offers secure offtake agreements, immediate access to technology and markets, and participation in the downstream lignin market.

- Turn-key integrated biomaterials solution for the P&P industry.

- Secure lignin offtake prior to investment decision.

- Have immediate access to technology, know-how, as well as global lignin markets, without adding resources or costs.

- P&P Co. participates in the downstream lignin markets, not just selling lignin for BTU value.

- Access to additional lignin converting technology as well as additional supply, including in different geographical regions.

- See renemat.com

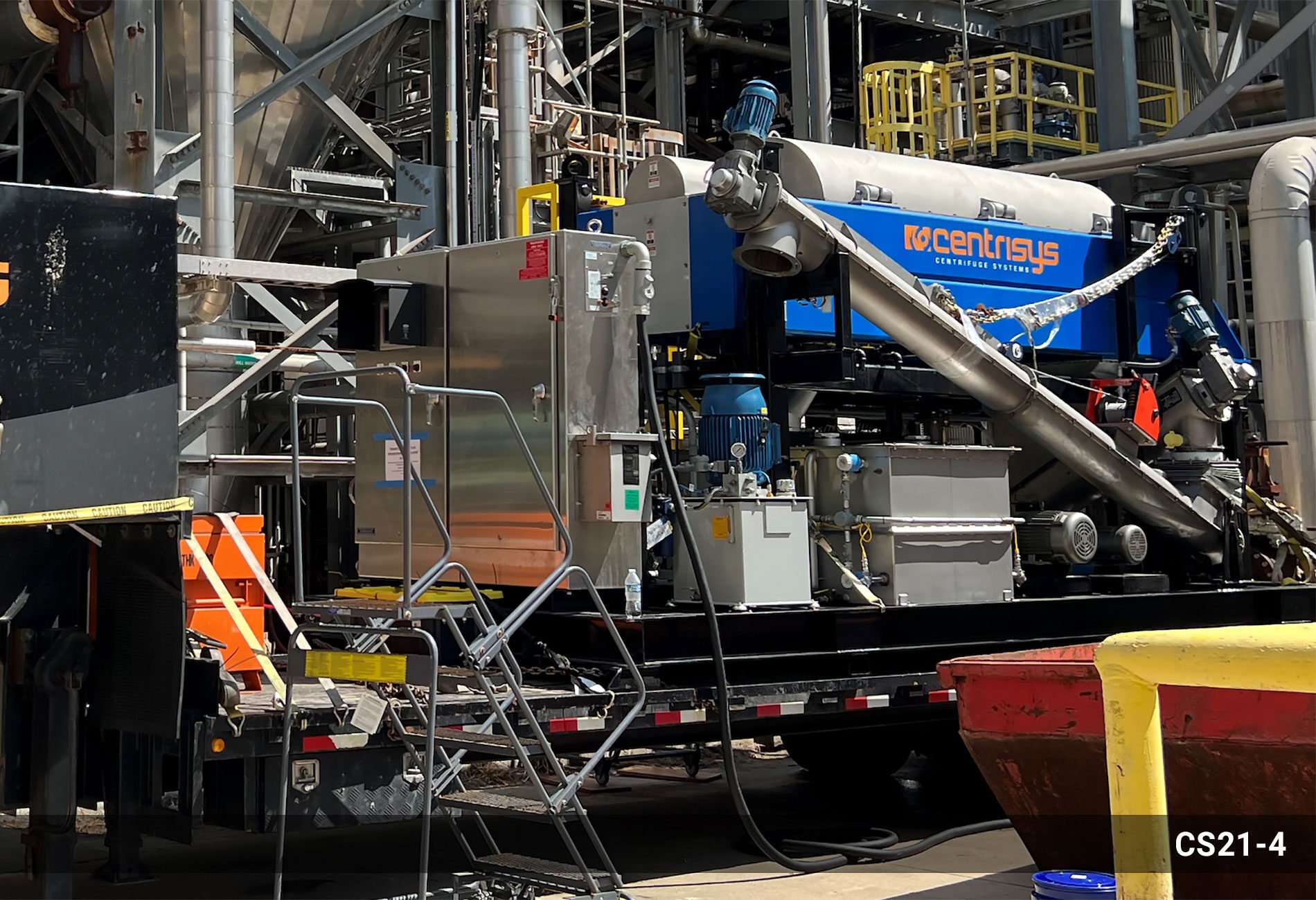

Decanter Centrifuge Technology Pilot Trial Option

Centrisys Renewables offers a pilot trial of our DCT for custom applications. The trial can help to determine equipment sizing and optimal locations. The trial typically includes:

- Site survey for the trial and for a permanent location at the mill

- DCT skid on trailer for flexible installation options

- Soft installation and operation of DCT by Centrisys/CNP

- Lab sampling and testing during the trial, as necessary

- Jointly review of trial results, best practices, and value proposition

Contact us for more information on our pilot trial options.

Interested in more?