Benefits of Decanter Centrifuges for Animal Waste & Manure Management

Dairymen and livestock producers manage over one billion tons of animal manure annually in the United States. With many dairy operations in the U.S. consolidating the number of cows concentrated on a single farm, proper handling of waste has become critically important and highly scrutinized by regulators, residents, and environmental groups.

The Centrisys DT decanter centrifuge (left pile) recovers the residual fines that remain in the manure after the slope screen (right pile) removes course material. The decanter centrifuge prevents these fines from being introduced to the lagoon and reduces the lagoon dredging.

The EPA concludes that a dairy farm with 2,000 cows generates more than 240,000 pounds of manure daily, or nearly 90 million pounds per year. The United States Department of Agriculture (USDA) estimates that manure from just 200 milking cows produces as much nitrogen as sewage from a community of 5,000 to 10,000 people.

Management of manure is growing in importance for dairymen given a variety of issues that range from the inherent desire to protect the environment and ensure profitability. It’s why more and more dairymen are taking a page from industries outside of the dairy and looking to decanter centrifuges for more effective separation of manure solids.

By using decanter centrifuges instead of conventional manure solids separation equipment, progressive-minded dairymen are coming out ahead in efficient separation, meeting regulations and profitability.

What Drives the Need for Better Solutions in the Separation of Manure Solids?

Efforts to effectively manage manure on dairy farms have been in place for more than 100 years, but there are a variety of reasons why the topic has risen to the forefront.

- The need to economically produce milk for the world, while minimizing the impact of farms on the environment.

- Regulators are increasingly looking to dairymen and others in the agricultural sector to address water quality and phosphorus emissions rather than putting the burden on wastewater treatment plants.

- An ongoing need to improve the bottom line through operational efficiencies, including more effective and cost-efficient ways to separate solids in manure slurry.

In light of the issues, dairymen have begun to incorporate decanter centrifuges into their manure management processes based on the advantages they delivery to separate manure solids.

Decanter Centrifuges for Manure Management

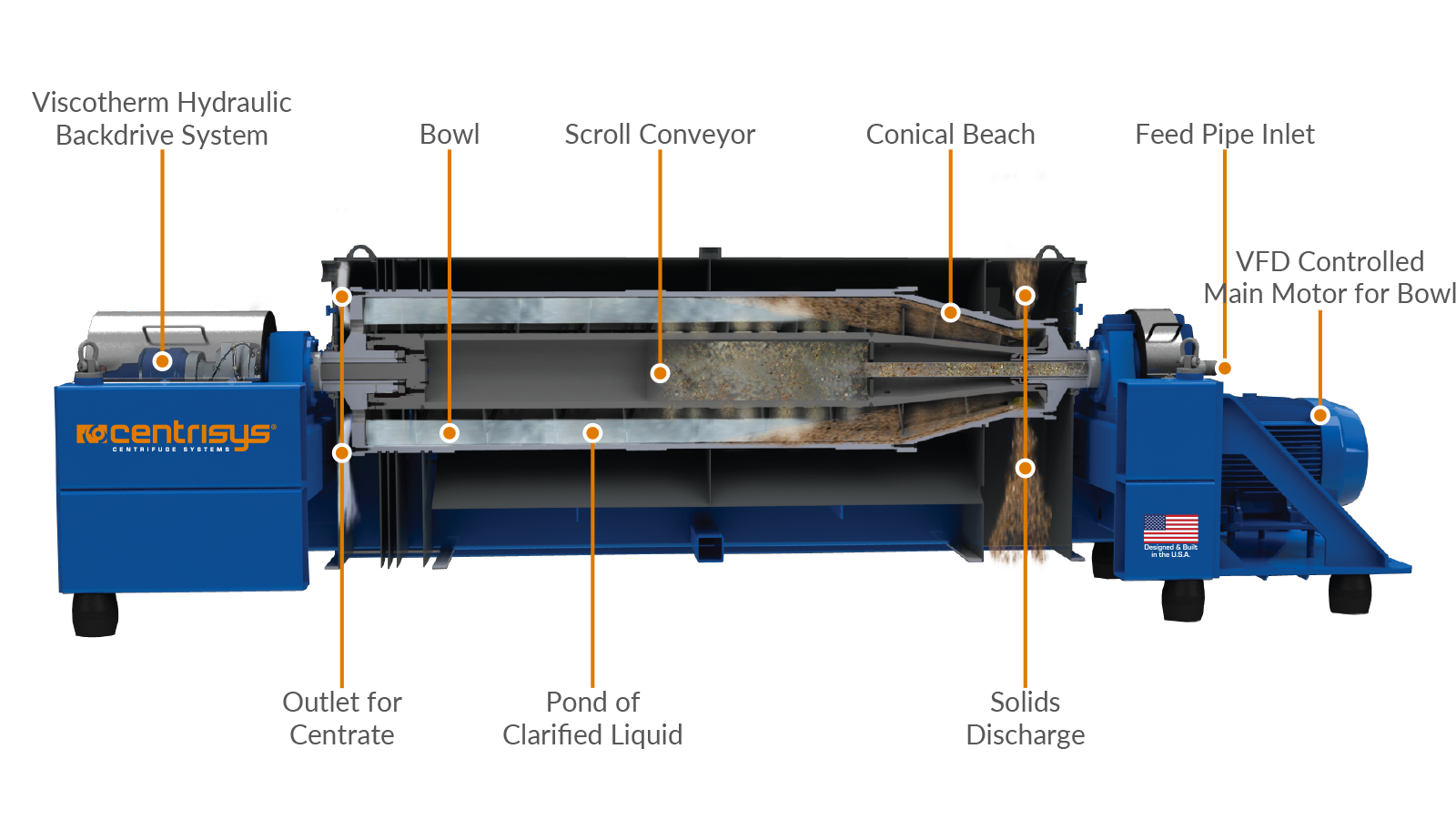

A decanter centrifuge is a self-contained machine that uses high rotational speed (centrifugal force) to separate solids and liquids, making it an essential component of wastewater treatment plants and plants in a host of other industries. The technology is also proving to be ideal for dairy farms.

Decanter centrifuges are used for solid-liquid separation of manure and wastewater that originates from washing areas and the process of flushing cow alleys.

Here's how a decanter centrifuge functions in a typical dairy operation:

- Manure slurry is fed into the intake point of the centrifuge.

- High-speed rotation separates solids from liquids in seconds. Heavy solids are forced to the outermost bowl of the unit.

- A scroll conveys the solids through the machine, where they are discharged through a designated outlet.

- Liquid is discharged through a separate outlet.

Every dairy operation has a different configuration. However, a decanter centrifuge can be readily incorporated into different manure processes – whether after manure removal from the barn, in conjunction with the sand separator or following anaerobic digestion. When necessary, polymers or coagulants can be added to the process to improve solids and nutrient recovery.

The incorporation of a decanter centrifuge into any dairy is driven by the characteristics of the operation since existing processes for manure management vary, as does the feed composition. Additionally, each setup must be optimized to produce the best results based on established goals. Care also needs to be taken when vetting dewatering options since not all decanter centrifuges are alike.

Operational and Environmental Advantages of Decanter Centrifuges for Manure Management

By incorporating a decanter centrifuge into its manure management processes, a dairy can meet the challenges and issues of manure and nutrient management head-on.

The advantages of a decanter centrifuge have to do in large part with the efficiency of solids separation. When compared to traditional separation equipment, multiple studies at dairy farms have shown that an optimized decanter centrifuge captures more total solids.

- In field studies, the decanter centrifuge demonstrated the ability to separate out considerably more solids when compared with conventional equipment - without the addition of coagulants and polymers. Use of such additives, however, also demonstrated the ability to further increase the level of solids and nutrients that can be separated.

- Decanter centrifuges are able to capture and separate finer particles from liquid manure versus traditional equipment

- Another advantage a decanter centrifuge delivers is low owning and operating costs. For one, the unit requires minimal day-to-day maintenance and cleaning when compared with screw presses, screens, and the like.

In the vast majority of cases, a single centrifuge can operate as a complete solids removal system, reducing the number of separate pieces of equipment needed.

Decanter centrifuges built specifically for busy dairymen are also designed for ease of use. Each decanter centrifuge is initially optimized around the processes and goals of each individual farm. The unit then runs continuously when required without the need for a full-time operator.

Economic Advantages of Decanter Centrifuges for Manure Management

The ability of decanter centrifuges to more efficiently separate manure solids allows dairymen to work smarter and meet their specific goals - while also helping to increase the profitability of the dairy in numerous ways:

- Bedding savings and revenue: A higher percentage of solids recovery eliminates the need for purchasing and hauling in bedding material. In some cases, dairymen can also make an extra profit by selling the excess solids as bedding material to other dairies.

- Lower lagoon treatment costs: More solids removal means less of it finds its way into the lagoon, sometimes saving tens of thousands of dollars annually on dredging and hauling costs, depending on the operation.

- Land application and storage benefits: Since more phosphorus is removed from the liquid manure, more of it can be applied to parcels of land. The ability to apply more manure on specific areas of land thus enables larger herds for a given piece of land. The process also results in ease of storage given the differences involved in storing a lower volume of solids versus a consistent volume of liquid. Solids can also be applied on-demand.

- Value-added solids: Since the solids contain higher levels of phosphorus in combination with other beneficial nutrients, it serves as a valuable fertilizer that can be stored and applied when fields are open, and crops need the extra boost in phosphorous. In some cases, the solids can be further stabilized through a composting or pelletizing process and sold commercially.

- Fertilizer savings: Whether it's liquid or solid manure, every pound can be used beneficially to save costs when compared to the expense of conventional fertilizer, given storage and application costs. In addition, because the coarse solids and much of the finer solids are removed, center pivots can be used to distribute liquid manure where local regulations and odor constraints allow.

- Water savings: dewatered manure with a low solids content can be recycled and used to wash sand bedding or flush barns, saving costs to acquire and treat water for the same purpose. Water savings are particularly important in areas where water shortages are a critical concern.

The Centrisys DT Model Decanter Centrifuge - A Custom Solution for Manure Management Developed by a USA Equipment Manufacturer

Compared to municipal waste, dairy manure is much more aggressive on a centrifuge. In 2007, Centrisys/CNP partnered with a leading dairy equipment provider to optimize a wastewater decanter centrifuge for dairy manure, address water quality and phosphorus emissions, maximize dewatering performance and minimize service frequency.

The result was the DT dewatering centrifuge specifically developed to handle dairy manure, and when compared with conventional equipment such as slope screens, drum screens, screw presses and other decanter centrifuges it:

- Separates up to three times the total solids without the addition of chemicals and polymers

- Achieves phosphorus removal of 50% or more without chemical additions, and 75% removal with chemical additions

- Lowers owning and operating costs due to ease of operation and maintenance

- Reduces lagoon dredging frequency

- Allows for utilization of recovered solids as bedding material or soil amendments

The DT Model decanter centrifuge is the first decanter centrifuge developed specifically for the manure industry and is a proven solution to ensure profitability and achieve environmental goals.

Case Study: Bettencourt Dairy Installs Centrisys CS26-4DT Series Decanter Centrifuge

Wendell, Idaho-based Bettencourt Dairy identified Centrisys’ CS26-4HCDT Series Decanter Centrifuge system as the optimal way to manage manure and has experienced incredible results and value from incorporating the system since installation in 2018.

Bettencourt Dairy houses over 13,000 dairy cows that produce 1,800 gallons of manure per cow per day - plus parlor water. Before the centrifuge installation, slope screens were used to remove coarse material, and farm operations personnel had to manage the dredging of the 200-acre waste lagoon once a year. The team was tasked with processing and addressing a nutrient management plan when they added cross-fence and vac trucks to remove the manure from the barns.

“We knew the Centrisys decanter centrifuge was designed to handle manure and the only piece of equipment that was going to be efficient enough to extract the solids, nitrates, and phosphates out of the water. This equipment was essential in growing and expanding our operation. Without added chemicals, it removes most of the solids - typically leaving less than 1% total suspended solids in the manure that previously went into the lagoons. It is the first piece of manure processing equipment we have put in place that worked from the beginning, the exact way that was promised to us.”

-Don Brand, manager of equipment and buildings with Bettencourt Dairy Operations.

Reduce Lagoon Dredging at a Dairy Farm with a CS26-4DT Centrifuge

Added Value Through Manure Management Partnerships

Aligning with dairy operation experts like Dairy Specialists, parlor and dairy design consultants, and Standley & Company, maintenance specialists for manure management systems, have been key factors for Centrisys in the integration of centrifuges within dairy applications.

In partnership with Dairy Specialists and Standley & Company, the team’s extensive knowledge and collaborative experience in the industry have allowed Centrisys to continuously improve on its initial system first used on a dairy farm.

Additionally, operations wouldn’t work as effectively for farms like Bettencourt Dairy without the support of locally-based service provider Standley & Company. Daily and weekly service checks, along with bi-monthly water material sample analysis, validate the efficiency of the system.

Are you ready to learn more about the use of Centrisys decanter centrifuges in the management of manure and other agricultural protein and byproducts? Contact the experts at Centrisys/CNP for an initial consultation.