Find Your Centrifuge Set Points: A Practical Guide

.png?width=1100&height=636&name=Untitled%20(42).png)

When operators face a new centrifuge application or when staff changes require re-establishing baseline settings, the multitude of control panel settings can feel overwhelming. You're looking at bowl speed, feed rate, polymer dosage, differential speed, pool level, and pressure set points all interacting at once. The pressure to get it right from the start is real, especially when your plant depends on consistent solids removal for compliance and operations. But here's what experienced operators have found: there's a logical process to take you from confusion to a properly tuned centrifuge. It doesn't require guesswork, and it doesn't require a PhD in centrifuge physics.

The Starting Point: Understanding Your Challenge Before You Touch the Dewatering Centrifuge

Operators often want to jump straight to the control panel, but facilities have found that the real optimization starts before you run a single test. You need three things in hand: your jar testing results (which tell you the right polymer type and dose), your feed solids percentage (which shapes your entire operating strategy), and a clear understanding of what a properly performing centrifuge actually looks like at your facility.

Doing this homework up front isn't extra work—it's the foundation that makes everything else work. When you understand what you're about to feed into the centrifuge, you can walk to that control panel with confidence instead of uncertainty. You'll know whether you're dealing with a challenging feed or a straightforward application. You'll know if your polymer choice is right for the shear forces inside your centrifuge bowl spinning at 3,000 RPM. These details matter because they shape every decision you'll make.

Three Essential Items Before You Start:

- Jar testing results - confirms the right polymer type and dose

- Feed solids percentage - shapes entire operating strategy

- Performance baseline - understanding what proper operation looks like at your facility

The Six Main Controls and Why They Interact

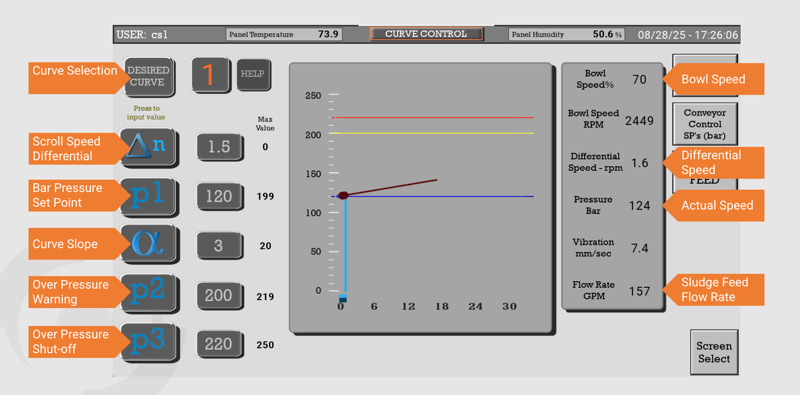

“Δ” Delta N (Base speed) is your minimum differential and does not need to be set, once established, usually at 1 rpm.

You set a pressure regulation start setpoint with P1, and the machine's automatic controller waits until that point is reached and then adjusts the differential speed to maintain the solids loading.

P1 needs to be set just below your normal operating pressure. (10-30 Bar below typically)

The “α” Alpha button adjusts how much of a reaction you get and is usually only set during initial optimization. Typically around 8-15 Bar/rpm) depending on the sludge characteristics.

Think of P1 as cruise control for your centrifuge. More solids arrive? The machine speeds up the scroll to move them out faster. Fewer solids? The dewatering centrifuge slows down the scroll to keep solids loading consistent. This happens automatically, without you adjusting anything.

While some operators prefer to play with settings constantly, other operators set it right and let the centrifuge do its job. The liquid residence time in the bowl is determined by the feed rate—it moves through relatively quickly. But solids residence time is determined by the differential and managed automatically by the controller. Understanding this distinction changes everything about how you approach optimization.

Control Interactions

| Control | Function | Impact |

|---|---|---|

| Bowl Speed | Determines G-forces inside machine | Affects separation efficiency & solids transport |

| Feed Rate | Controls material volume entering | Determines liquid residence time |

| Polymer Dosage | Flocculates solids for separation | Directly affects centrate clarity |

| Differential Speed | Moves solids out of machine | Controls solids residence time & cake dryness |

| Pool Level | Controls liquid volume in bowl | Affects clarification area |

| P1 Set Point | Controls solids retention time | Main parameter after commissioning |

The Physics Trade-Off: Why Slower Sometimes Works Better

Here's where many operators hit their first counterintuitive moment. Conventional thinking says: faster bowl speed equals better performance. And technically, higher G-forces do create cleaner centrate by forcing finer particles out of the liquid. But those same high G-forces can actually inhibit the screw conveyor's ability to transport them up the conical against this G-force and out of the machine. Higher G-force can cause solids transportation problems, excessive wear, noise, higher polymer dosage and higher power consumption.

Most facilities have found that a lower bowl speed—around 80-95%—often gets better overall results, especially when the feed includes a lot of inorganic materials. Lower G-forces mean the scroll can move solids more easily, therefore resulting in cleaner centrate as there is more clarifying volume available. You can always increase speed later if cake dryness isn't sufficient, but you'll do it from a position of understanding what the machine is actually capable of at your site.

Reading Your Centrifuge: The Centrate Tells You Everything

Here's a practical diagnostic tool that separates experienced operators from new ones: watch the centrate, especially during first startup, when the dewatering centrifuge is not fully loaded yet. That liquid flowing out is your fastest, most immediate indicator of what's happening inside the centrifuge. If it's dirty or you see tiny pin flocs floating around the moment you start up, the issue is almost certainly polymer-related—wrong type, wrong dose, or poor contact time with the sludge. It's not the centrifuge speed.

The centrate will show you polymer problems within seconds. Your solids? They take 5 to 10 minutes to respond to a change because of their slow residence time through the centrifuge. This timing difference is crucial. It means if you start your run and something's wrong with the centrate, you can address it quickly. You don't have to wait to see how wet the cake is.

And if the centrate is slimy and you can literally dip your fingers in and pull out strings of polymer, you're overdosing—wasting money on polymer that the dewatering centrifuge can't use. The goal is a clear liquid and dry, crumbly solids. Think fine, powdery potting soil coming out of the discharge. That's success.

Polymer: The Control You Can Actually Optimize

Getting polymer right matters more than most operators realize. Inside a centrifuge running at 3,000 RPM, you have an environment of intense shear forces. Cheap, linear polymers designed for belt presses literally get torn apart in those conditions. You need a branched or cross-linked polymer specifically designed for centrifuges—one with a molecular structure that can withstand that shear, high molecular weight and often a higher charge as well.

Yes, centrifuge-grade polymers cost more upfront than standard options. But here's the math: if your polymer can't handle the shear, you have to overdose it significantly to get any flocculation at all. You're possibly spending more money to get worse results. A good polymer, applied at the right point (far enough upstream to have contact time with the sludge), does the heavy lifting and lets your centrifuge do what it's designed to do.

The visual cue is simple: if you can pull strings of polymer from your centrate, dial it back. You've got too much. The goal is a dosage level that gives you clear liquid without any polymer fingerprints.

If you see clear water and settled flocked solids on the bottom, a higher differential should do the trick. (Lower P1 setting)

Another important factor is contact time. If you can add the polymer further away from the centrifuge, the contact time between polymer and sludge increases and often makes it a lot more efficient and reduces polymer consumption.

Try different polymer addition points to find the best location. Polymer injection rings, mixers and aging tanks can further stretch your polymer dollar!

Your Startup Strategy: Conservative and Deliberate

When you're starting fresh at your facility, experienced operators follow a deliberate sequence rather than guessing. Start with a lower bowl speed 80% to reduce G-forces and make solids transport easier. Start with a lower feed rate to prevent clogs during startup. Be generous with polymer initially; it's easier to dial back later than to chase your tail trying to catch up. And watch the centrate the entire time. It's your feedback loop.

This conservative approach establishes a stable baseline. Once you're running smoothly and your solids are coming out dry, then you can optimize. But you can't optimize from chaos. You need a starting point that works.

The Two Rules that Separate Success from Frustration

Experienced operators know that technical knowledge means nothing without discipline in how you apply it. There are two non-negotiable rules when you're fine-tuning:

- Rule of Simplicity: Change only one variable at a time. If you adjust feed rate and polymer dosage simultaneously, you'll have no idea which change actually made a difference. You'll be chasing your tail. Isolate your variables so cause and effect are clear.

- Rule of Patience: Wait at least 10 minutes—sometimes longer—before making another adjustment. Your centrate will show you polymer changes quickly. Your solids? They're moving more slowly through the machine. They take time. Make an adjustment, set a timer, and wait. Then look at the results. This is how you learn what your machine actually needs.

Skipping these steps is why some operators feel like their centrifuge is a black box. It's not the machine's fault. It's impatience and trying to change everything at once.

Finding the perfect setting is trial and error. There is no “one-size-fits-all” setting.

The Feed Consistency Reality

Here's the most important thing experienced operators understand: you can have the most perfectly optimized centrifuge in the world, but its performance is completely at the mercy of what you're feeding it. A centrifuge can't compensate well for inconsistent feed. If your incoming sludge varies dramatically—different solids percentages, different characteristics, different polymer needs—your carefully dialed-in set points won't hold.

Maintaining your feed consistency is critical. A facility with consistent feed solids can dial in settings and leave them. A facility with highly variable feed may need to accept more variation in results or invest in better feed conditioning.

Understanding the Two Types of Retention Time

Centrifuge optimization requires understanding how different operational parameters control material processing time. Decanter centrifuges actually manage two distinct retention times, each controlled by separate variables.

Liquid retention time depends on feed flow rate. Since incoming feed typically contains 98% water, the volume of liquid entering the centrifuge closely matches the centrate volume exiting once the bowl fills. Higher feed rates reduce liquid retention time; lower feed rates extend it.

Solids retention time is controlled by differential speed—the small difference in rotational speed between the bowl and internal scroll. This speed difference makes the scroll function like a conveyor, moving separated solids, once settled toward the discharge openings. Lower differential speed extends the time solids remain in the machine, allowing more thorough dewatering and producing drier cake solids. Higher differential speeds move solids out faster, reducing dryness but increasing throughput capacity.

Facilities optimize performance by monitoring centrate clarity as the primary indicator. Clear centrate signals effective separation, allowing operators to reduce differential speed for maximum cake dryness. Cloudy or dirty centrate indicates excessive solids retention, requiring differential speed increases.

Maintaining Performance During Optimization

Facilities adjusting centrifuge parameters follow systematic approaches to maintain separation efficiency while optimizing solids dryness. When increasing feed flow to boost throughput, polymer dosage must increase proportionally since higher feed rates introduce more solids requiring flocculation.

The relationship between variables creates an optimization process facilities navigate by monitoring the centrate quality. As long as centrate remains clear, differential speed can be reduced to extend solids retention time and increase cake dryness. When the centrate becomes cloudy during adjustments, the differential speed has dropped too low, causing excessive solids accumulation that overloads separation capacity.

This balance between throughput, chemical usage, and product quality allows facilities to find operating points that meet specific discharge requirements and operational constraints.

Optimization Protocol (During Initial Setup):

- When increasing feed flow rate, increase polymer dosage proportional to the increase in dry solids mass entering the centrifuge (not just flow rate)

- Monitor centrate quality as the primary indicator

- During optimization: If centrate remains clear, you may incrementally reduce differential speed to extend solids retention time for a drier cake

- If centrate becomes cloudy at any point, the differential speed is too low

- Increase the differential speed by one increment to restore clarity

- Find the optimal balance point where centrate remains clear at the lowest differential speed that maintains clarity

Making It Real: From Confusion to Confidence

Getting a centrifuge properly optimized is actually quite logical. It's about understanding how the centrifuge actually works—the automation, the physics trade-offs, the role of polymer, the timing of different responses. It's about following a disciplined process rather than making random adjustments. And it's about watching the right indicators and changing one thing at a time.

The control panel doesn't have to be mysterious. When you understand that the dewatering centrifuge is largely regulating itself through the pressure regulation, when you know why slower can sometimes be better, and when you focus on what the liquid is telling you rather than guessing, that black box becomes a predictable instrument you can tune with confidence. Your plant gets the consistent solids removal it needs. Your compliance stays solid. And you know exactly what you did to make it happen.

FAQS

How do I know if my centrifuge polymer dosage is too high?

If you can dip your fingers in the centrate and pull visible strings of polymer between them, you're overdosing. The centrate should be clear without slimy texture. Overdosing wastes money without improving cake dryness.

How does feed flow affect polymer dosage requirements?

Polymer dosage must remain proportional to solids loading. When feed flow increases, or solids % increases, more solids enter the centrifuge, requiring proportionally more polymer for effective flocculation and separation. Facilities adjust polymer dosage in proportion to feed rate changes while monitoring centrate clarity as the primary performance indicator.

Why is my centrifuge cake still wet even at high bowl speeds?

Incorrect sludge conditioning or solids transportation problems. Higher G-forces can inhibit the screw conveyor's ability to transport solids. Start with lower bowl speeds 80% to improve solids conveyance before increasing speed for clarification. Low solids content in feed or excessively high pool level can also cause wet solids.

How long should I wait after making a centrifuge adjustment?

Wait at least 10 minutes before making another change. The centrate responds quickly (seconds to minutes), but solids take 5-10 minutes to show results due to longer residence time through the machine.

How do I know what differential speed to use?

Start with manufacturer recommendations, then adjust based on centrate quality. As long as centrate remains clear, differential speed can be reduced to extend solids retention time and produce drier cake. If centrate becomes cloudy during adjustment, differential speed is too low and should be increased. The optimal setting balances cake dryness requirements against throughput needs.

What's the difference between regular polymers and centrifuge-grade polymers?

Centrifuge-grade polymers are branched or cross-linked to withstand the intense shear forces inside a bowl spinning at 3,000 RPM. They are also typically at a higher charge and higher molecular weight. Linear polymers break apart under these conditions, forcing you to overdose for similar results.

Should I adjust bowl speed or feed rate first when optimizing?

Change only one parameter at a time and wait 10 minutes between adjustments. Start with lower bowl speeds and lower feed rates during startup, then gradually optimize individual parameters once the machine runs stable.

What does P1 pressure set point actually control?

P1 is your main adjustment to control the amount of solids inside the bowl. It is the point of pressure where regulation starts. The actual pressure needs to be above P1. The automatic controller adjusts differential speed to maintain solids loading—like cruise control that speeds up on hills (more solids) and slows on downhills (fewer solids).

P1 lower gives cleaner centrate, P1 higher gets drier cake.

Why is my centrate dirty right from startup?

If centrate is dirty immediately at startup, the issue is almost always polymer-related (wrong type, dosage, or concentration)—not machine speed settings. Check your jar testing results and polymer injection point.

How far upstream should I inject polymer before the centrifuge?

Give robust polymers more contact time with sludge by injecting further upstream from the feed point. This allows the polymer more contact time to work more efficiently before encountering the high-shear environment inside the bowl, reducing the required dosage.