4 SIMPLE Tips to Reduce Struvite Formation in a Decanter Centrifuge

Visual Inspection is Key to Battling Struvite Build-Up on Your Decanter Centrifuge

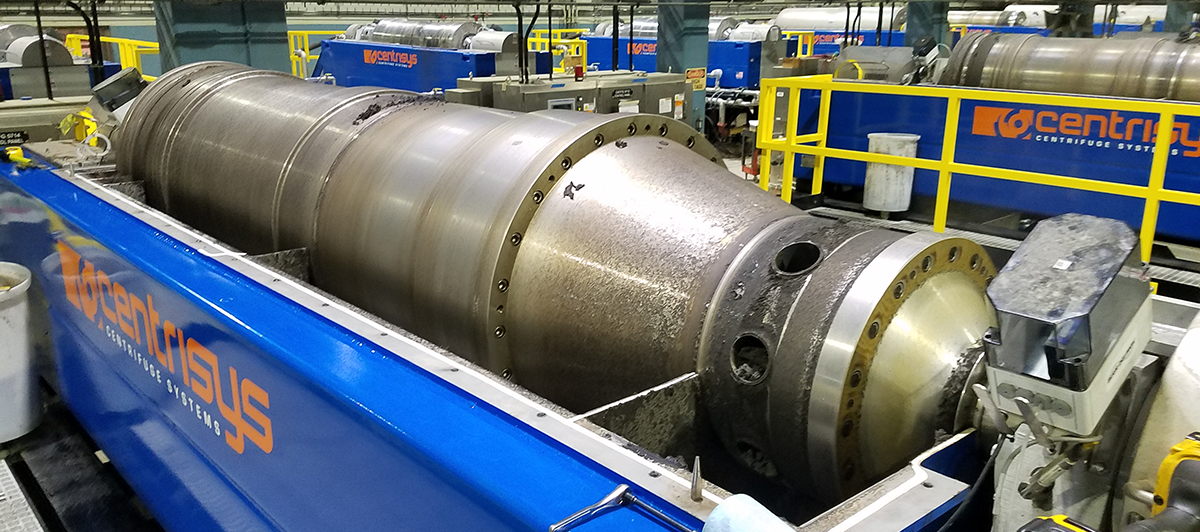

Struvite formation is common in municipal and industrial treatment plants. Struvite scaling forms in pipelines, pumps, digesters, belt presses, and centrifuges. If a centrifuge is left unchecked, the struvite build-up will eventually cause damage, increase equipment repairs, and decrease plant efficiency.

Four simple tips will help you reduce or prevent struvite build-up in your decanter centrifuge.

LEFT: Gouges on the centrifuge bowl from struvite increase maintenance costs.

RIGHT: Struvite forms on the inside of pipes, increasing maintenance time at a plant.

1. Struvite formation is predictable. Know the orthophosphate levels in your plant’s sludge.

Struvite (NH₄MgPO₄·6H₂O) is a mineral consisting of magnesium, ammonium, and phosphorus, common molecular compounds found in municipal and industrial sludges. Struvite crystals form when magnesium, ammonia, and phosphate combine in sludge. Sludge temperature and pH are additional contributing factors to struvite precipitation.

- The higher the pH in the sludge/slurry, the more likely the formation of struvite crystals.

- Struvite formation most frequently occurs in wastewater treatment plants that have anaerobic digestion but will form in other operations and industries.

- Because of air entrapment, the pH increases and struvite builds when exposed to the air that exits dewatering equipment.

PRO TIP: Measure your plant’s orthophosphate levels by performing a standard in-house lab test. If the orthophosphate (PO₄-P) is over 50 mg/l, your centrifuge is susceptible to struvite scaling, so monitor it regularly. Contact our sample analysis team for more information.

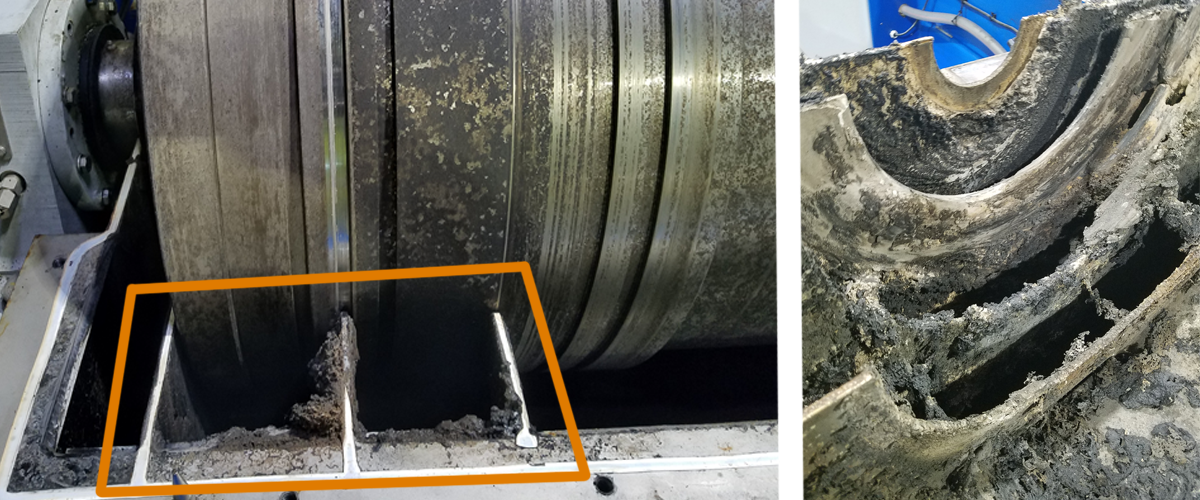

LEFT: Struvite on the lower centrifuge housing baffles, with a rotating assembly.

RIGHT: Struvite on the lower centrifuge housing baffles, without a rotating assembly.

2. A visual inspection will identify struvite formation in the centrifuge.

Open the decanter centrifuge cover and:

- Inspect the centrate (liquid) end of the centrifuge housing. This area of the centrifuge is typically the most prone to struvite scaling. If struvite is present, you will see it first on the stationary baffles and inside the centrifuge housing. Struvite crystals appear as white to yellowish-brown crystal prisms. It will be dry, hard, and sharp.

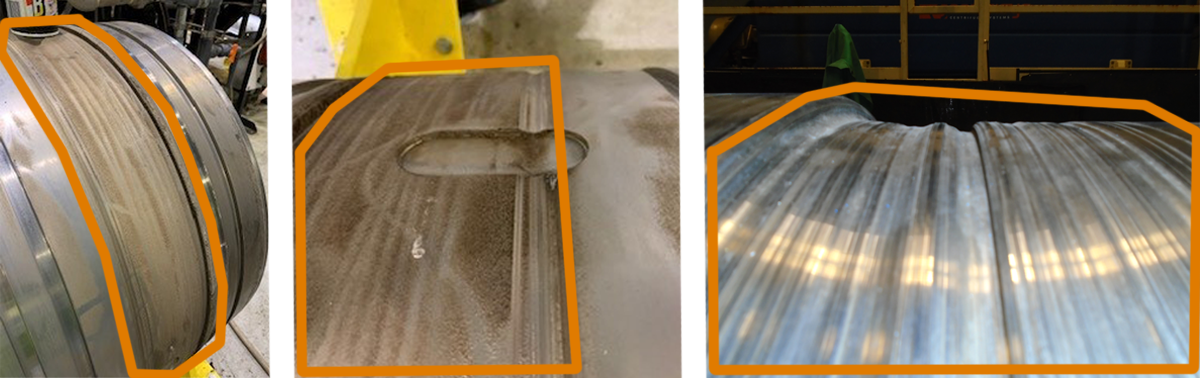

- Look for shiny marks on your centrifuge bowl. This is an indicator that struvite is rubbing against the bowl. Struvite adheres and collects to the stationary parts and components inside the centrifuge housing. As the bowl rotates, the struvite crystals rub against it, forming gouges or ruts to the outside of the bowl. If the struvite buildup is not removed it will continue accumulating, causing larger gouges and more damage to the bowl.

- Is the solids discharge suddenly very wet? This could be a warning that struvite accumulation is happening in the centrate pipe. This build-up can restrict the free flow of the centrate, resulting in its backup to the housing, causing additional damage and very wet solids discharge.

PRO TIP: Monitor your centrifuge’s main drive power consumption for sudden increases. The struvite build-up inside the housing can cause a drag on the centrifuge bowl and increase power consumption. The centrate piping restricted by struvite can cause centrate backup and increase power consumption.

Bowl erosion from struvite formation on the centrifuge housing baffles.

3. Frequent centrifuge struvite maintenance is far more efficient and less time-consuming than delaying until significant struvite accumulation is visible.

Plant phosphorous levels determine how frequently a centrifuge requires struvite cleaning. When struvite forms on the stationary baffles, it is critical to minimize the build-up before the struvite comes into contact with the centrifuge bowl.

Methods to Descale Struvite from a Centrifuge:

- Mechanical Removal: metal scrapers are standard tools for struvite cleanup on a centrifuge. Use tools such as chisels and hammers carefully. If used too aggressively, these tools can cause additional damage.

- Power Washing: This is typically the least effective method depending on the amount of struvite build-up. For any centrifuge maintenance task, it’s essential to know the proper power washer procedures.

- Acid Washing: A light spray of ferric or citric acid directly onto the struvite can help dissolve precipitation. Ferric chloride reduces the pH of the sludge and is used to bind the soluble orthophosphate preventing struvite formation. Use with caution. Acids are highly corrosive and can lead to steel pipe failures throughout the plant.

PRO TIP: If it's necessary to send the rotating assembly to a service center, a spare centrifuge rotating assembly stored at your plant will minimize process downtime.

LEFT AND MIDDLE: Struvite build-up along the lower housing baffles form gouges on the centrifuge bowl.

RIGHT: Struvite build-up on the centrifuge bowl is visible from the centrate discharge end inspection hatch.

4. Ask us about MagPrex™ and CalPrex©, two long-term solutions for struvite precipitation.

If your plant has costly uncontrolled struvite formation, Centrisys/CNP has two proven phosphorous reduction processes:

Both processes reduce the total phosphorus in the sludge, increase dewatered cake dryness, and reduce polymer usage and maintenance costs.

Do you have additional questions about struvite formation in your centrifuge or other plant areas? Centrisys/CNP’s experienced service technicians are always available to assist you. Contact the experts at Centrisys/CNP today.