Decanter Centrifuge Spare Rotating Assemblies Explained

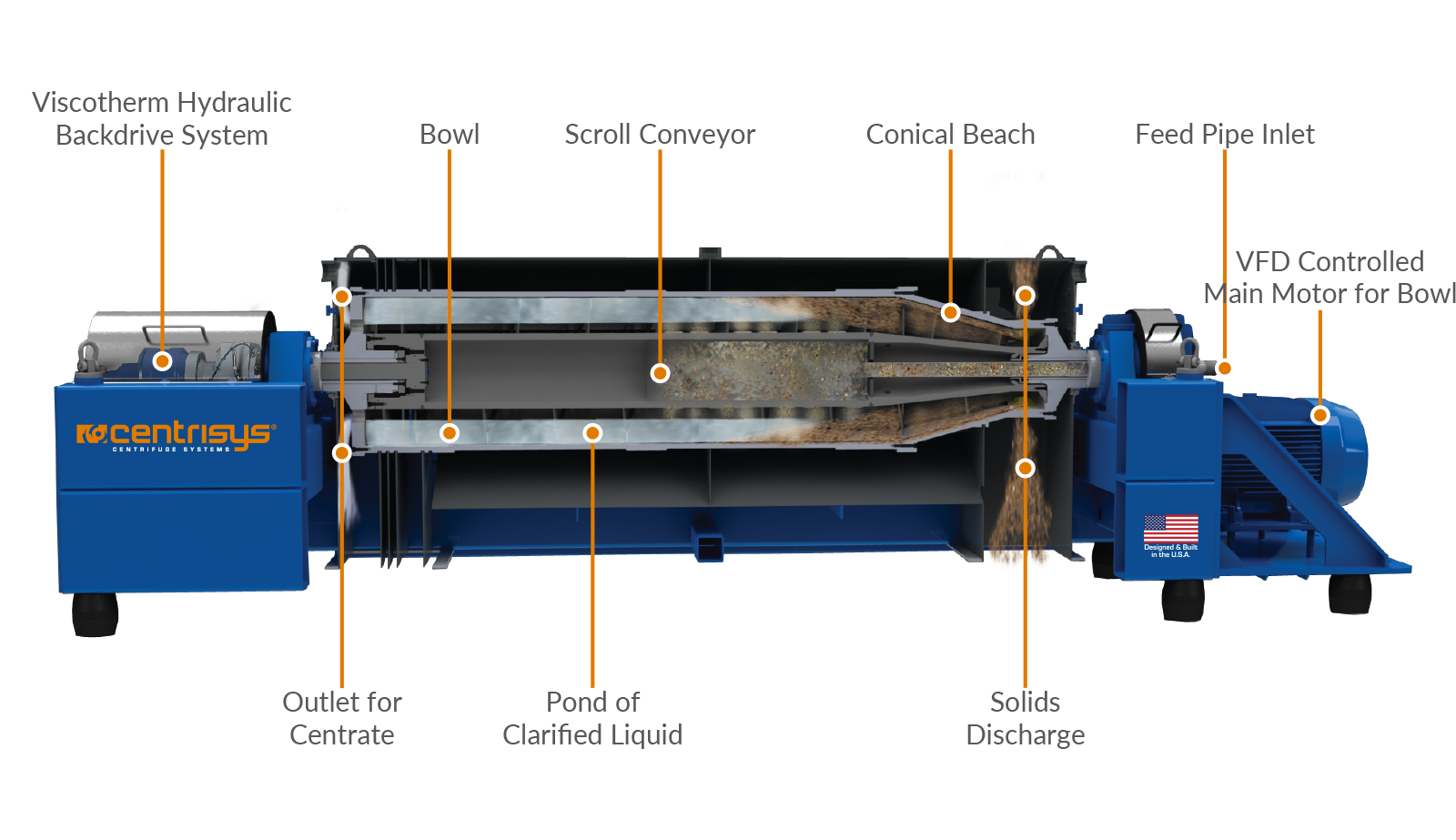

A decanter centrifuge is used for sludge dewatering and sludge thickening. As a complete piece of equipment, it includes a centrifuge frame, the housing, control panel, main motor, back drive (hydraulic or gearbox), lubrication system, and a variety of sensors, solenoids, monitors, and last but not least the rotating assembly (RA), which we like to call “the guts” of the equipment.

Watch our on-demand webcast where George Kueppers, Centrisys/CNP VP, Product Innovation discusses the three types of spare rotating assemblies and best practices for decanter centrifuge maintenance and repair.

Understanding the Decanter Centrifuge Rotating Assembly

The rotating assembly has two main components: the centrifuge bowl and a scroll (screw conveyor). An electric motor drives the bowl. The internal scroll, which operates at a slightly different speed than the bowl (this is called differential speed), is driven by a radial piston hydraulic motor.

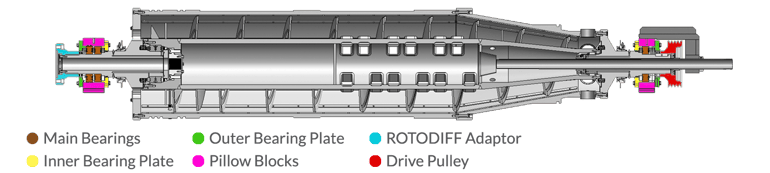

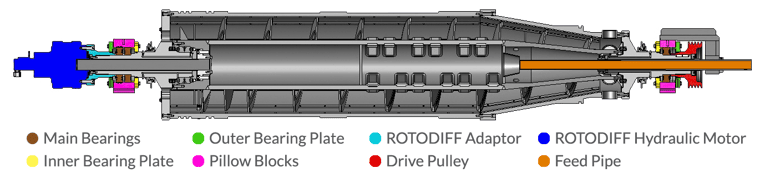

In a cross-section or exploded view, you can identify many different components, both internal and external. The external components are what differ among the three spare RA options we’ll discuss in this blog post.

What are the Advantages of Having a Decanter Centrifuge Spare Rotating Assembly?

The most significant advantage of keeping a spare rotating assembly on hand is the ability to minimize unplanned downtime during sludge dewatering or thickening operations. With a spare RA ready to go, an on-site swap can typically be completed in just six to eight hours—allowing your plant to stay up and running with minimal disruption.

In addition, a spare RA gives your team the flexibility to properly inspect, repair, and optimize the damaged assembly without the pressure of rushing to get it back online. Quick, temporary fixes often lead to bigger issues down the road, making this flexibility a valuable asset.

It’s also important to recognize that all rotating assemblies will eventually require a rebuild due to normal wear. This is especially true in abrasive applications, where rebuilds are needed more frequently. Having a spare RA allows your operation to continue uninterrupted while the damaged unit is sent to a service facility for a comprehensive rebuild.

In short, a spare RA is a smart investment in both uptime and long-term equipment health.

Let’s take a closer look at the specific advantages and key considerations for each type of spare rotating assembly.

1. Bearing to Bearing

The Bearing to Bearing Rotating Assembly uses the existing pillow blocks (also called bearing housings). This assembly includes the inner main bearings and the bearing plates.

ADVANTAGES:

- Minimizes plant downtime

- Reusing the pillow blocks is the most flexible option when multiple centrifuges are in a plant

- If the existing pillow blocks are re-used and are not damaged, an alignment is not necessary; this is because the pillow blocks are already aligned with the centrifuge frame

- Provides the necessary time to thoroughly inspect, repair, and optimize the damaged assembly at a Centrisys/CNP repair facility

- With this assembly, the pillow blocks from the original RA(s) are used on every centrifuge in the plant

- The drive pulley, hydraulic drive, and adapter are used from the original assembly

- Before assembly of the spare RA, the bearing housings should be inspected for damage; if damage is found, they will need to be repaired or exchanged; in that case, the pillow blocks will need an alignment

- A thorough inspection of the centrifuge is recommended after an assembly exchange

BEARING ALIGNMENT PROCESS:

- During alignment, a dial indicator checks alignment from top to bottom and side to side

- After alignment, a tapered or straight pin is installed to ensure repeatability in future installations

- Different machines may require different pin types, but precision is key

Learn how to diagnose bearing damage on your decanter centrifuge.

2. Full Spare Rotor

The Full Spare Rotor is an assembly that includes new centrifuge bearing housings, a new drive pulley, and the ROTODIFF adapter.

* A Full Spare RA does not include the ROTODIFF Hydraulic Motor.

ADVANTAGES:

- Allows for a quick RA swap onsite - reducing operational downtime

- Provides time to thoroughly inspect, repair, and optimize the damaged assembly at a Centrisys/CNP service facility

- Covers possible damage to the feed pipe or brackets from plugged machines

- Service and repair of the original assembly include the inner main bearings and plates, drive pulley, adaptor, and pillow blocks

- After initial alignment, future swaps can be completed in less than two hours

- Requires a one-time, on-site pillow block dial-in alignment

- Does not include the hydraulic motor or gearbox

- Bearing housings cannot be moved between machines without alignment

- After the pillow blocks are aligned with the frame, they are pinned (using a roll-pin or conical pin); the alignment procedure guarantees correct positioning after installation

- If multiple centrifuges are on-site, the dial-in and pinning procedures are necessary for each centrifuge

- A thorough inspection of the decanter centrifuge is recommended after the RA exchange

Having a spare rotating assembly on hand is the smartest way to keep your operation running when the unexpected happens. By partnering with a trusted decanter centrifuge manufacturer like Centrisys/CNP, you’ll also gain access to fast, expert repair solutions and emergency support.

3. Complete Spare Rotor

The Complete Spare Rotor is an assembly as if it was lifted from the centrifuge frame. This version includes the centrifuge feed pipe and the ROTODIFF Hydraulic Motor.

ADVANTAGES:

- Allows for the quickest RA swap with the least operational downtime

- Provides the necessary time to properly and thoroughly repair the original RA at a Centrisys/CNP service facility

- The repair of the original assembly is the most comprehensive; it includes the inner main bearings, bearing plates, drive pulley, adaptor, pillow blocks, and back drive (either gearbox or hydraulic)

- Requires a one-time, on-site pillow block dial-in alignment

- Ideal when purchased with a new centrifuge, alignment is done at the factory

- After the pillow blocks are aligned with the frame, they are pinned (using a roll-pin or conical pin); the alignment procedure guarantees correct positioning after installation

- If multiple centrifuges on-site, the dial-in and pinning procedures are necessary for each centrifuge

- A thorough inspection of the decanter centrifuge is recommended after an RA exchange

Additional Points to Consider

- Standard procedures and tooling are necessary to dial-in a centrifuge rotating assembly

- When the RA dial-in is required, NEW roll pin locations are necessary; do not rely on the original taper pins or metaligner locations

- The pillow blocks have one additional location to install a set of pins

- A plant with multiple centrifuges benefits best from the Bearing to Bearing Rotating Assembly because of its versatility

Preventive Maintenance and a Spare RA: Your Best Defense Against Downtime

Routine preventive maintenance is essential to extending the life of your decanter centrifuge and keeping it operating at its best. Regular inspections, timely bearing replacements, and proper lubrication practices all play a vital role in catching early signs of wear before they escalate into major issues.

But even the most proactive maintenance plans can't prevent an unexpected failure that may require an on-site repair or off-site rebuild. That's where having a spare RA on-site becomes invaluable. Together, preventive maintenance and a spare RA strategy offer the most reliable way to reduce unplanned downtime, lower long-term repair costs, and keep your plant running smoothly under any condition.

Check out our ‘How-To’ series and get expert insights into how to properly operate and maintain your decanter centrifuge.

Ready to Improve Your Decanter Centrifuge Strategy?

Whether you're weighing the benefits of a spare rotating assembly or looking to improve your preventive maintenance plan, Centrisys/CNP is here to help. With decades of experience and a deep understanding of decanter centrifuge performance, our team can guide you toward the right solution for your plant’s needs.

Want to learn more about spare rotating assemblies and how Centrisys/CNP can be your trusted partner for service and repair? We’re ready to help you minimize downtime and maximize efficiency.

Reach out to one of our knowledgeable centrifuge technicians today!