How Important is the Bowl Wall Thickness on a Decanter Centrifuge?

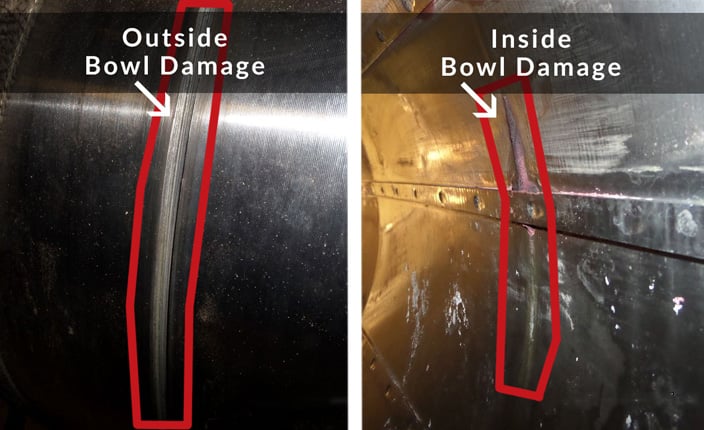

Evaluation: Our service team was surprised that not only was the bowl distorted, but there was also visible damage on the INSIDE of the bowl. We realized that the bowl wall thickness was only 6 mm. With our 30+ years of centrifuge experience, our opinion is that a decanter centrifuge should have a 16-18mm bowl wall thickness (ours is 18 mm). If the bowl wall was our recommended 16-18mm, this would have been cosmetic damage and the centrifuge could have ran for many more years.

Conclusion: The customer had two options: to replace the centrifuge bowl or replace the entire centrifuge. The customer chose the latter. Smart decision. If the bowl wall thickness was so obviously ignored, what other major problems were around the corner? Keep plant operators safe, don’t ignore quality. CAPEX is yesterday’s news.