Decanter Centrifuge Systems

Biosolids Equipment For Solid/Liquid Separation

Decanter Centrifuges Engineered to Exceed Customer Expectations

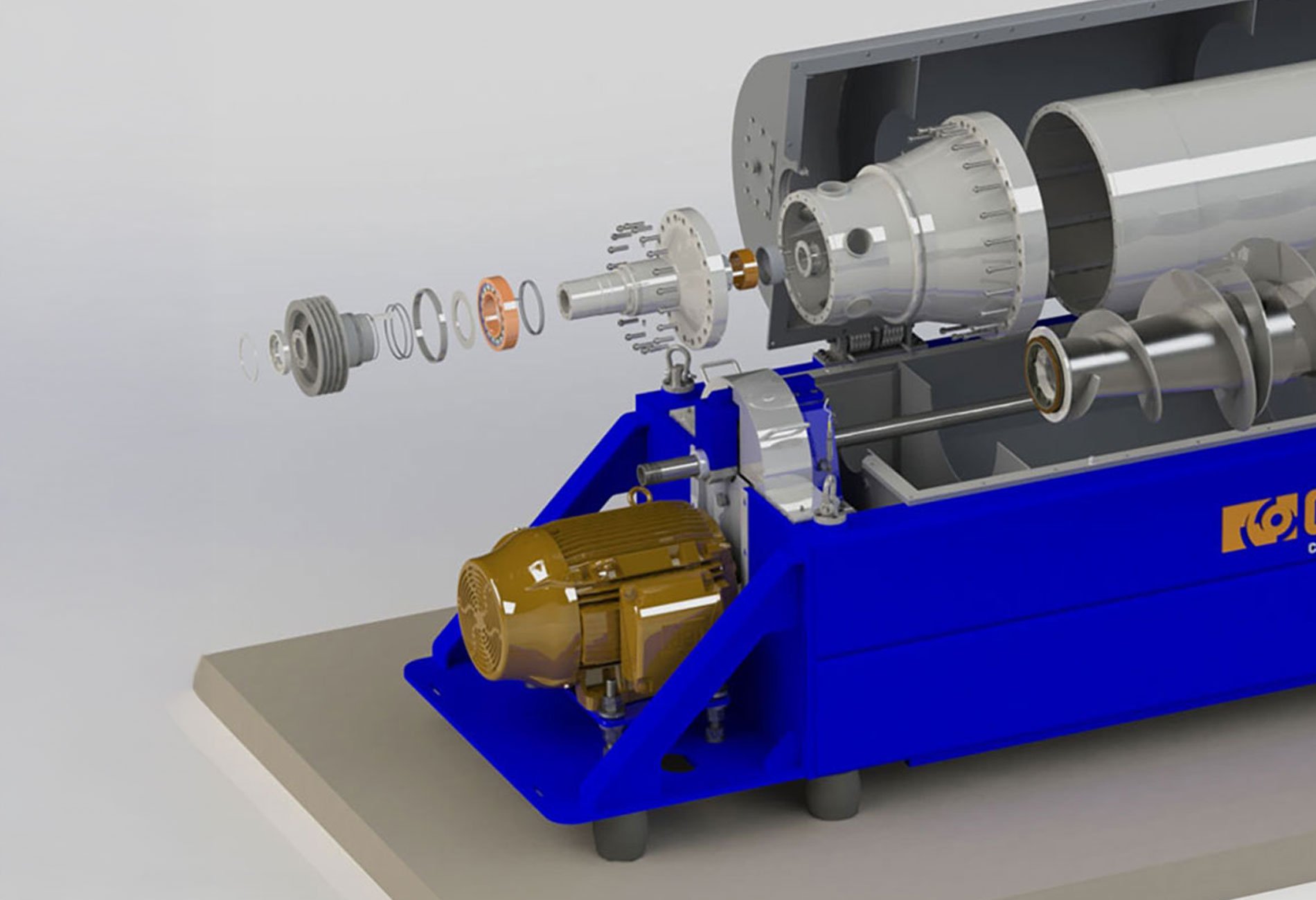

Customer-driven decanter centrifuge technology has been at the core of Centrisys since the beginning. This value-added approach to centrifuge design gives us the upper hand to understand why most sludge dewatering and thickening processes are best served using different combinations of decanter design features. It's our decades of experience servicing all brands of decanter centrifuges, along with our broad range of Centrisys centrifuge designs from standard, semi-standard to fully customized decanter centrifuge systems that set us apart in the industry today.

Decanter Centrifuges and Biosolids Equipment for Sludge and Slurry Treatment

Centrifuge Innovation and Non-Stop Optimization are Key to Our Success. The Centrisys line-up of treatment equipment for biosolids, designed to deliver the highest quality for superior performance and the lowest cost-of-ownership to our customers around the world.

Dewatering Centrifuge - CS Series

The Centrisys Decanter Centrifuge Standard. Delivers the lowest cost of ownership - Reduced energy consumption - Maximum uptime.

Sludge Thickener - THK Series

Our Patented Centrifuge Sludge Thickener. The most innovative solution to thicken all types of sludge. No polymer performance.

Low-Temperature Belt Dryer - DLT Series

Compact - Low Profile - Modular Design USA Parts - Ideal for Energy Recovery

Vertical Cuttings Dryer - CD Series

A vertical scroll screen centrifuge designed to recover base fluids and reduce hydrocarbons from drill cuttings.

Decanter Centrifuge Rentals

We offer fast, convenient and reliable decanter centrifuge rentals for short-term sludge dewatering and thickening.

Mobile Systems

Consider the simplicity of an American-Made plug-n-play containerized, skid or trailer mounted centrifuge system.

Advantages

Discover why Centrisys/CNP is your perfect partner, providing you with the best dewatering solutions in the industry.

Service & Repair

Our combination of experience and expertise specific to centrifuge technology gives us the upper hand for service and repairs on ALL centrifuge brands.

Customized Solutions

Learn why custom decanter centrifuges for sludge dewatering and thickening are the Centrisys standard.

Related Topics

Features and Benefits

See the Centrisys centrifuge dewatering process difference.

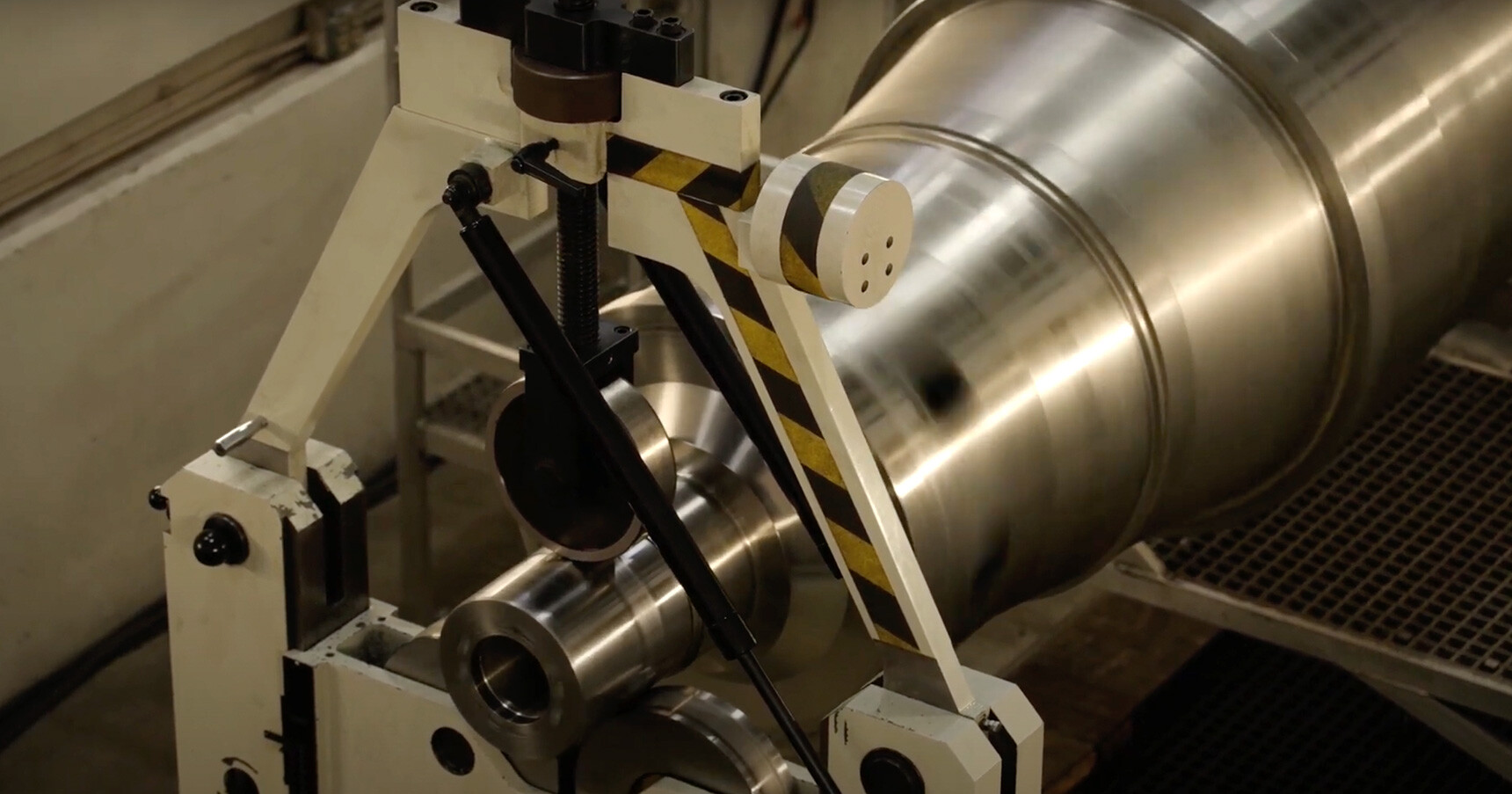

Decanter Centrifuge Balancing

Optimizing performance & efficiency for best performance

Comprehensive Guide

Understanding Decanter Centrifuge Operation, Service, Maintenance, and Repair

Advanced Centrifuge Design

Experience the RotoDiff Hydraulic Backdrive - the most advanced centrifuge backdrive available.