If you were thickening both the waste activated sludge (WAS) and the primary sludge (PS), have you looked at the benefit of hydrolyzing both? Is there any benefit, or do you recommend hydrolyzing just the WAS?

The only time you want to hydrolyze primary sludge (PS) is when your goal is to achieve Class A biosolids with a thermal hydrolysis process (THP) and mesophilic anaerobic digestion (MAD). More than 90% of the benefit from the THP comes from TWAS hydrolyzation as thickened waste activated sludge (TWAS) which is much harder to digest than primary. Hydrolyzing PS would mean twice the size of the THP system, more than double the caustic soda amount, and a cooling heat exchanger to cool down the hydrolyzed PS+WAS from 160 °F to 100 °F. In summary, it would require almost twice the capital cost to hydrolyze PS+WAS together and twice the OPEX with little benefit. A better way would be to thicken the primary sludge to about 6% and blend it with the Lysed TWAS to achieve maximum benefit in terms of increased digester capacity and improved energy balance for the solid’s treatment train.

Can you comment on comparing CAMBI’s thermal hydrolysis system (THP) with PONDUS for medium-sized wastewater treatment plants?

Sure, I think there are four main points to mention:

- PONDUS uses significantly less polymer. For the PONDUS THP, we thicken to 6% with little to no polymer (0-2 lbs./DT) vs. pre-dewatering at CAMBI, which thickens to 12-15% dry solids (DS) and requires 12-15 lbs./DT of polymer.

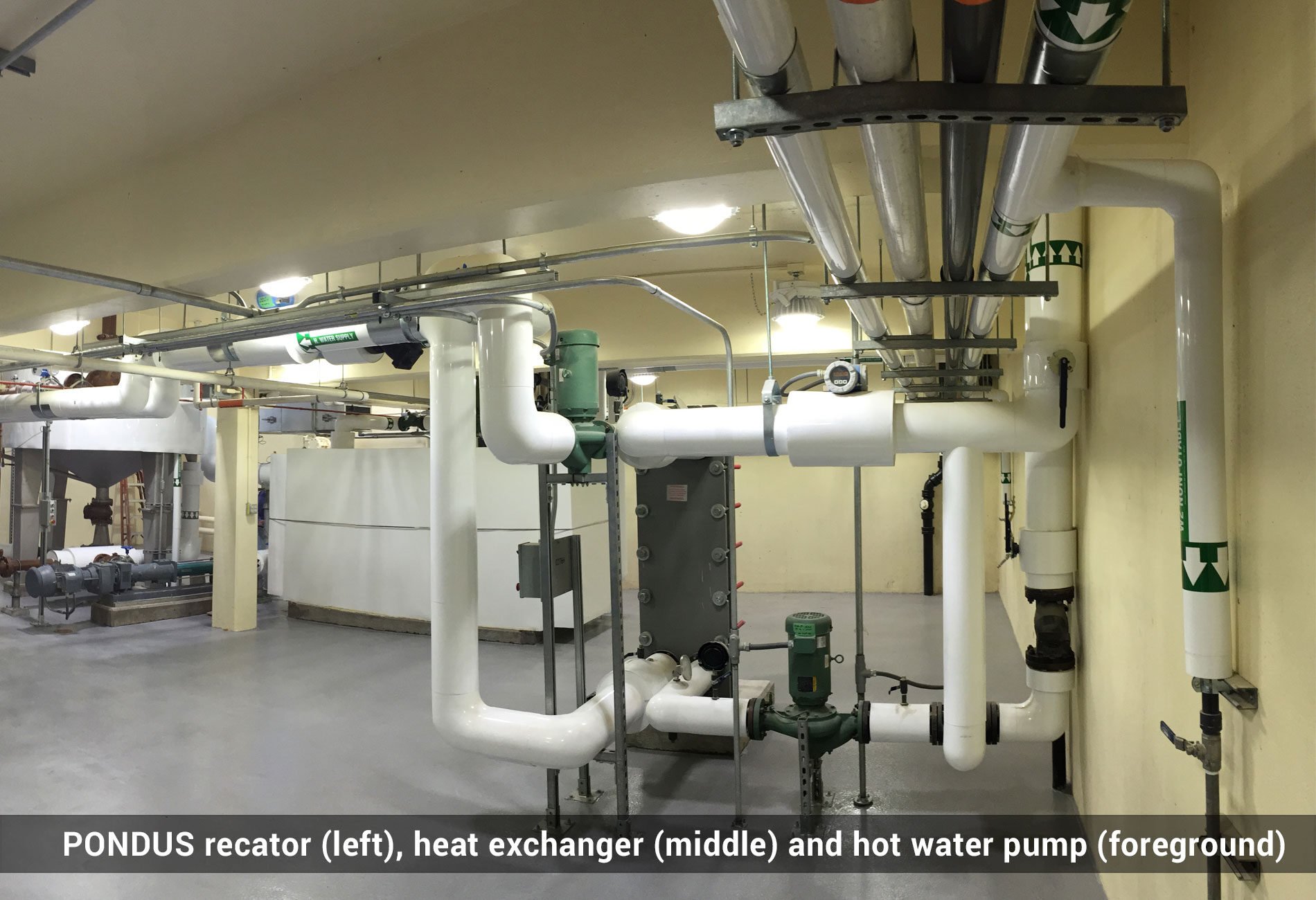

- PONDUS is easier and less costly to operate and maintain. Our installation in Kenosha, a 28 MGD facility, hired one person to run the THK sludge thickener, PONDUS, and dryer. Every wastewater treatment plant has the staff to operate and maintain PONDUS THP, which consists of PC pumps, a heat exchanger, a stainless-steel reactor, caustic soda tanks, and simple instruments such as IDMs and temperature gauges. No pressure vessels, and no boilers. The system easily fits indoors due to its compact footprint, which is a much smaller footprint than Cambi’s THP.

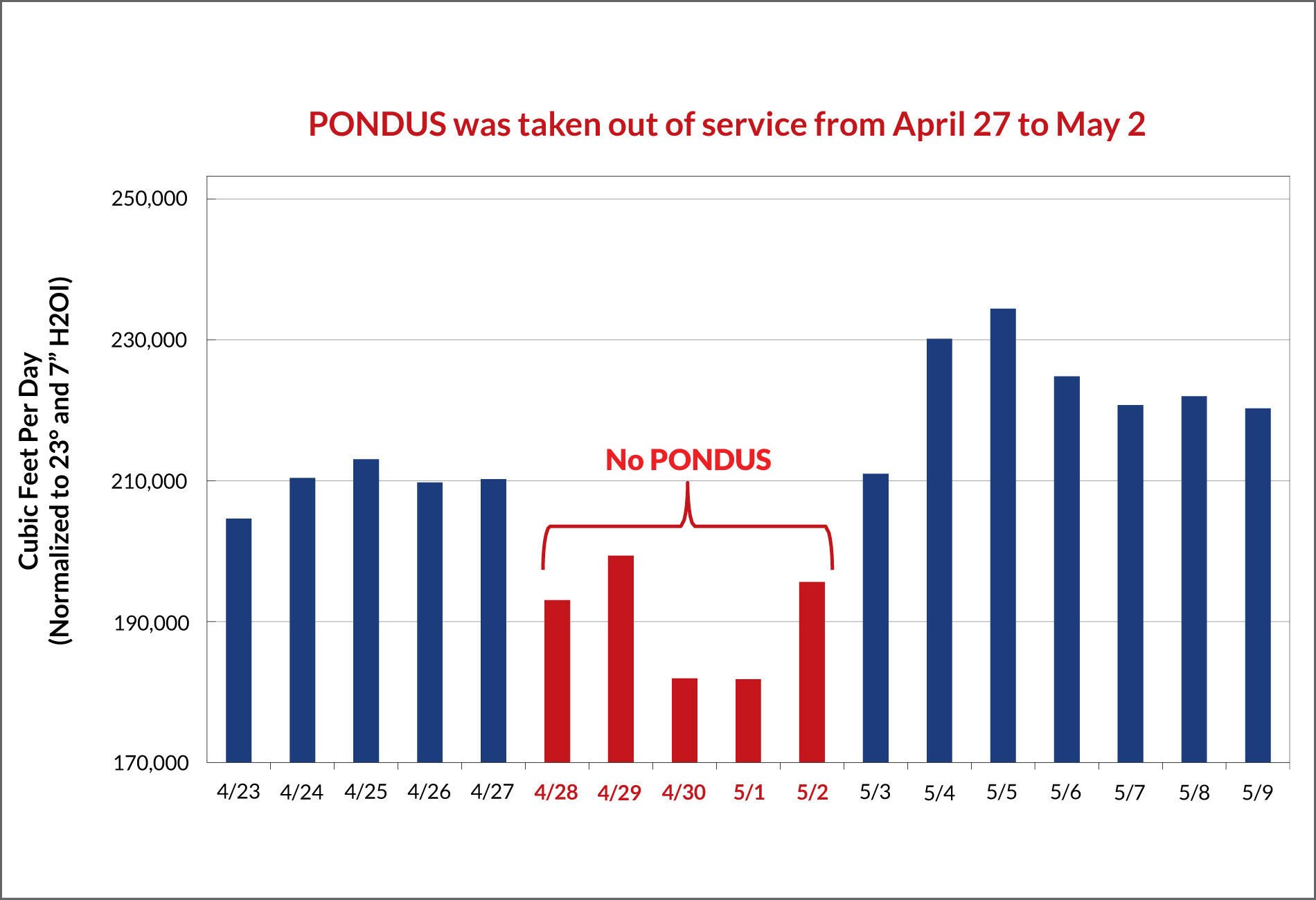

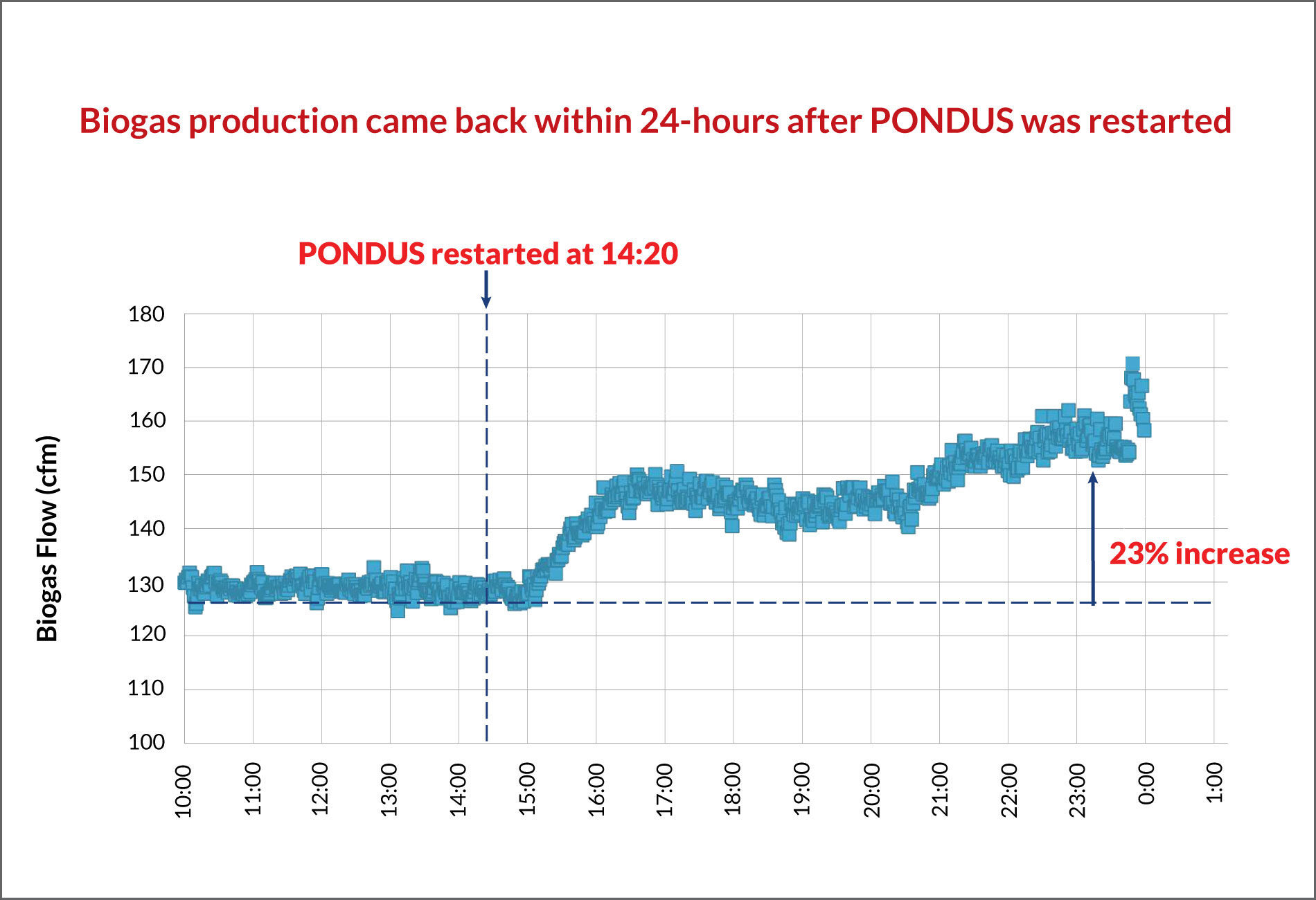

- Simple start-up and run time. Recently a PONDUS installation at Erlangen was started up in 24 hours. Uptime in Kenosha is >95%.

- Lower side-stream loading rates for PONDUS THP, especially for ammonia. No discoloration of centrate with PONDUS THP.

Regarding Bio-P, if facilities have issues with struvite coming out of their digesters, then the thermal hydrolysis process will probably worsen the problem. Would you recommend a phosphorous removal process, like P-recovery or sequestration, for such applications?

Absolutely! If a plant operates with biological phosphorus, then phosphorus removal should be part of the discussion with or without thermal hydrolysis. THP will increase the loading rates of both phosphorus and nitrogen, making P removal even more vital. We would encourage our clients to see this as an opportunity to recover phosphorus paired with THP. Since the loading rates are higher with THP, there might even be an economic case to recover the phosphorous in fertilizer form and obtain an ROI for that process. If you do it before the digester, you can use a technology like CalPrex. Post anaerobic digestion, we recommend MagPrex for struvite sequestration or recovery. Please contact us for more information and we would be happy to answer any questions regarding P-sequestration or recovery.

For more details on how a PONDUS system works, please see Reduce Sludge Volume: PONDUS Thermal Hydrolysis Process (THP).