How to Clean a Decanter Centrifuge

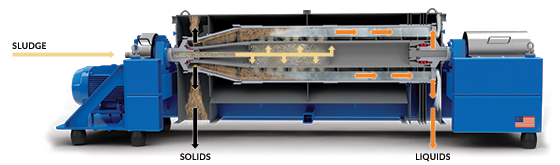

A dewatering decanter centrifuge, also known as a horizontal bowl centrifuge or solid bowl centrifuge, is a machine used to separate solids (sludge, slurry) from liquid(s).

- 2-phase separation separates one solid from one liquid in one process step

- 3-phase separation separates a solid from two liquids of different densities in one process step

Routine Centrifuge Predictive and Preventive Maintenance

To keep a decanter centrifuge operating at its optimal level, a maintenance schedule should include daily, weekly, monthly, and annual measures. Trained plant operators can perform many if not most of these on-site.

Download a helpful guide with a full decanter centrifuge predictive and preventive maintenance schedule here: Suggested Plant Maintenance Guidelines.

Flush Water Cleaning Guidelines for Centrisys Decanter Centrifuges

Decanter centrifuges require routine flushing to discharge the feed material on the internal components. If a centrifuge is not flushed correctly the remaining solids in the centrifuge will collect on one side or at the bottom of the centrifuge during standstill. This will create unnecessary and/or high vibration at start-up. The flush volume depends primarily on the centrifuge size.

If the flow of the flushing liquid (typically water) is too low, vibration may occur due to unbalance. A low speed flush is the most effective at 10-20% speed but excessive flush water can cause leaks around the feed tube or housing seals. Adjust the water flow for application and equipment size specifics. Water is usually sufficient to flush, although some processes may require cleaning agents or warmer water to be the most effective. Water for flushing should be free of contaminants that can cause solenoid malfunctions and chemically inert.

IMPORTANT NOTE: Do not shock the centrifuge.To avoid thermal shock and mechanical damage it is important that flushing water temperature is within 30°F from the centrifuge and feed liquid temperature. As a general rule of thumb, if the process is hot: use hot water. If the process is cold: use cold water.

Because a centrifuge develops a vacuum in the center at the feed tube during operation, high water pressure is not a requirement for a flush cleaning. Water pressure only needs to be sufficient to provide proper flow based on the centrifuge size. In general, this is between 40-80 PSI at rated flows.

Below is a general chart for water flow requirements: As a rule of thumb this is about 40-60 % of rated max flow.

| Machine Size | Feed Flow Max Rating GPM* | Minimum Flush Water GPM |

| CS10-4 | 30 | 10-18 |

| CS14-4 | 55 | 20-35 |

| CS18-4 | 100 | 40-60 |

| CS18-4 HC | 125 | 50-75 |

| CS21-4 | 180 | 72-110 |

| CS21-4 HC | 225 | 90-135 |

| CS26-4 | 380 | 150-200 |

| CS30-4 | 450 | 180-250 |

| THK200 | 250 | 50 |

| THK350 | 500 | 100 |

| THK600 | 1,100 | 150-200 |

* Maximum feed flow based on very specific conditions and not necessarily available.

Decanter Centrifuge Cleaning Modes

Cleaning or flushing a centrifuge is a simple but critical maintenance process. It's used to remove as many solids as possible from the bowl and the scroll after operation, and/or before the next start-up. If solids are left inside the bowl, they will stick to the internal bowl wall. This creates an unbalanced centrifuge. When imbalance occurs, its common to hear louder than usual noise and centrifuge vibrations will be more agitated.

There are two types of centrifuge cleaning modes for typical wastewater applications:

1. Auto Stop Wash Cycle

Auto Stop Wash Cycle occurs during a normal Auto Stop shutdown. It’s a shorter wash cycle, initiated while the centrifuge is running and used when it will be down for a brief period of time. The auto-stop sequence begins one of two ways:

- If a system shutdown alarm goes off, the centrifuge controls automatically begin the sequence

- An operator manually starts the sequence from the auto-stop sequence screen

2. CIP (Clean in Place)

CIP (Clean in Place) is a cleaning process used typically in food and beverage processes. It’s an automatic flush sequence that operates in a similar manner to the Auto Stop and Auto Start sequence, except the sludge and polymer feed do not turn on. It is an extra, low-speed flush that’s programmed as a separate sequence used when the centrifuge is not running.

Learn more about decanter centrifuge cleaning modes auto stop and CIP here.

Should Chemicals Be Used to Clean a Decanter Centrifuge?

It’s important to understand the effect cleaning chemicals may have on equipment. In some cases, chemicals used to clean a decanter centrifuge may do more harm than good. For example, a concentrated acid solution should never be left in a decanter centrifuge overnight, or for a longer period. The bonding material used to hold the tungsten carbide tiles to the centrifuge scroll and backup plates will dissolve. This occurs because of the low pH of acidic cleaning solutions. Over time, even highly chlorinated effluent used for flushing the centrifuge can weaken the solder bond. In a typical wastewater application, warm water is sufficient to clean a decanter centrifuge.

Check out more do’s and don’ts of cleaning a decanter centrifuge here.

Damaged flights due to chemicals.

How to Power Wash a Decanter Centrifuge:

Failure to follow proper cleaning protocols during and after power washing may cause damage to the centrifuge, its parts and ancillary equipment.Before power washing:

- Follow all lockout-tagout procedures

- Make sure the centrifuge is not running and is powered off and at stand-still

- Ensure the operator is using the proper PPE

It’s ok to use a power washer to clean a centrifuge if the main motor, main bearings, and electric connectors such as the junction box are protected from the direct water spray of the power washer. This can be accomplished by covering parts in plastic. Not protecting the centrifuge properly during power washing may lead to rust and corrosion.

After power washing:

To prevent bearing damage after power washing, it's important to run your centrifuge every week, even if just for a few minutes.

If your centrifuge is in storage or not operating for a period of time after cleaning, it’s important to keep the bearings lubricated by running the centrifuge for a few minutes each week. Rotating the bowl by hand for a few turns each week also helps. This procedure moves the lubricant around; it keeps the rolling elements in the bearings coated in lubricant and shields them from damaging moisture.

Ongoing Decanter Centrifuge Preventative Maintenance

How often are you performing routine decanter centrifuge maintenance? Knowing the condition of your centrifuge or sludge thickener will reduce repair and operating costs and enhance performance reliability and efficiency. In addition, putting a forward-thinking centrifuge maintenance plan into place allows for proactive budgeting, extending the life of the centrifuge and creating a safer environment for your plant operators.

For these reasons and more, Centrisys has developed the Centrifuge Service Inspection (CSI) Program, a 40+ point inspection for your decanter centrifuge or sludge thickener. Learn about this program here.

Do you have questions about the best ways to maintain and clean your decanter centrifuge? Centrisys/CNP’s experienced technicians are always available to provide recommendations and guidance. Contact us today.