8 Reasons THK Addresses Plant Operation Challenges

| 1. |

Proven NO POLYMER performance

|

| 2. | 50% LESS POWER consumption compared to other centrifugal sludge thickening technologies |

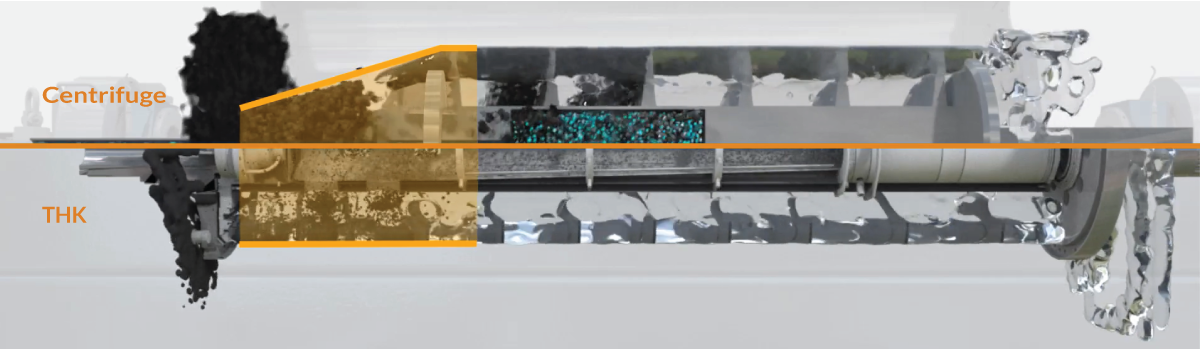

| 3. | All cylindrical design provides the GREATEST G-VOLUME compared to other centrifuges of similar bowl diameter |

|

|

| 4. |

Optimization is a SIMPLE, two-step approach

|

| 5. |

2-3x the solids concentration

|

| 6. |

Enclosed system increases HYGIENIC OPERATION and OPERATOR SAFETY

|

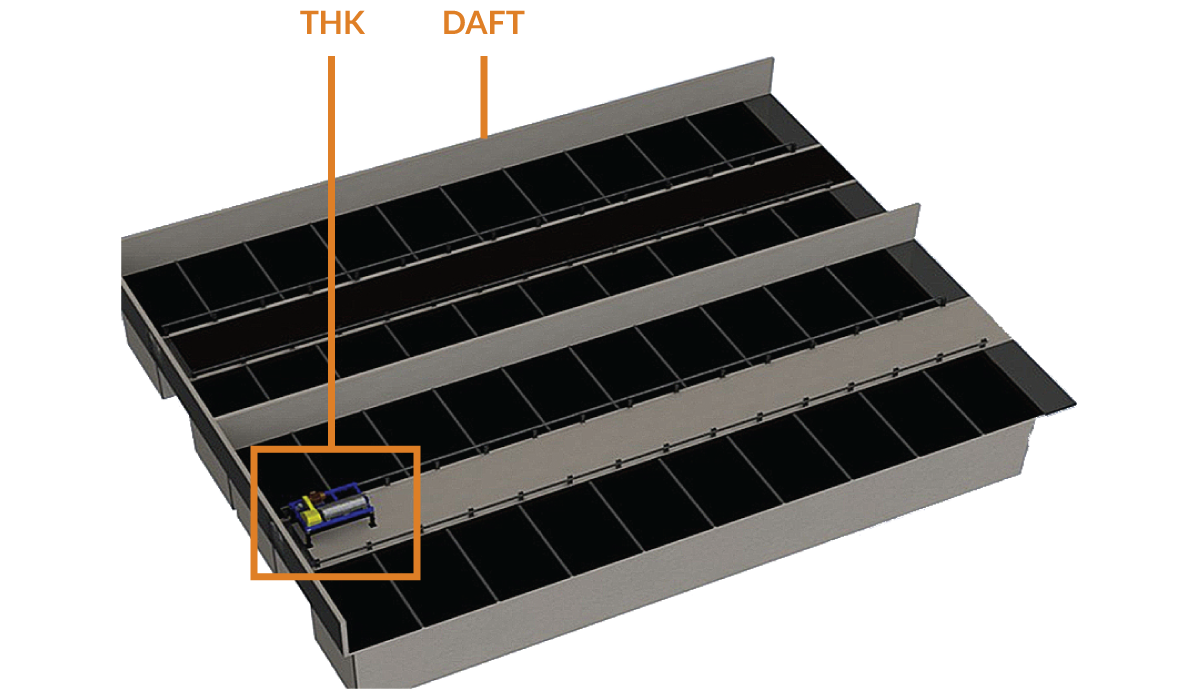

| 7. | SMALLEST FOOTPRINT efficiently utilizes available plant space |

|

|

| 8. | THK Lease+ Program is a LOW-RISK option to own a THK without spending more than your current operations budget |

Need more proof? Check out our THK case studies.