Should You Change Your Decanter Centrifuge Bowl Direction?

Centrisys Explains the Difference Between Leading and Lagging with a Hydraulic Backdrive

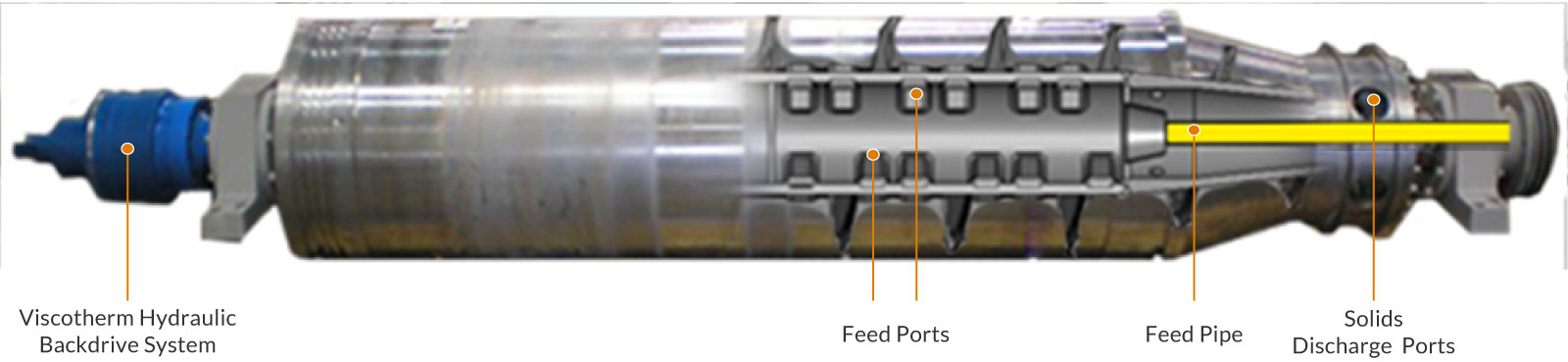

Decanter centrifuges are not created equal. One of the key differences with a Centrisys decanter centrifuge is the Viscotherm ROTODIFF® hydraulic backdrive. Our standard hydraulic backdrive technology allows a Centrisys centrifuge to rotate the centrifuge bowl in two different directions called leading or lagging.

What is a leading and lagging direction?

All decanter centrifuges rotate the bowl and scroll in the same direction, but centrifuge mechanical and hydraulic backdrives operate differently.

Centrisys centrifuges' enhanced capability provides maximum efficiency from just one centrifuge. Thanks to the combination of innovative engineering and the ROTODIFF®, hydraulic backdrive - the centrifuge operation gives users two separate scroll modes: leading or lagging.

The centrifuge differential speed, controlled by the ROTODIFF® hydraulic backdrive, allows a Centrisys centrifuge bowl to rotate as.

- A leading scroll, faster than the bowl.

- A lagging scroll, slower than the bowl.

What are the advantages of operating a Centrisys decanter centrifuge as either leading or lagging?

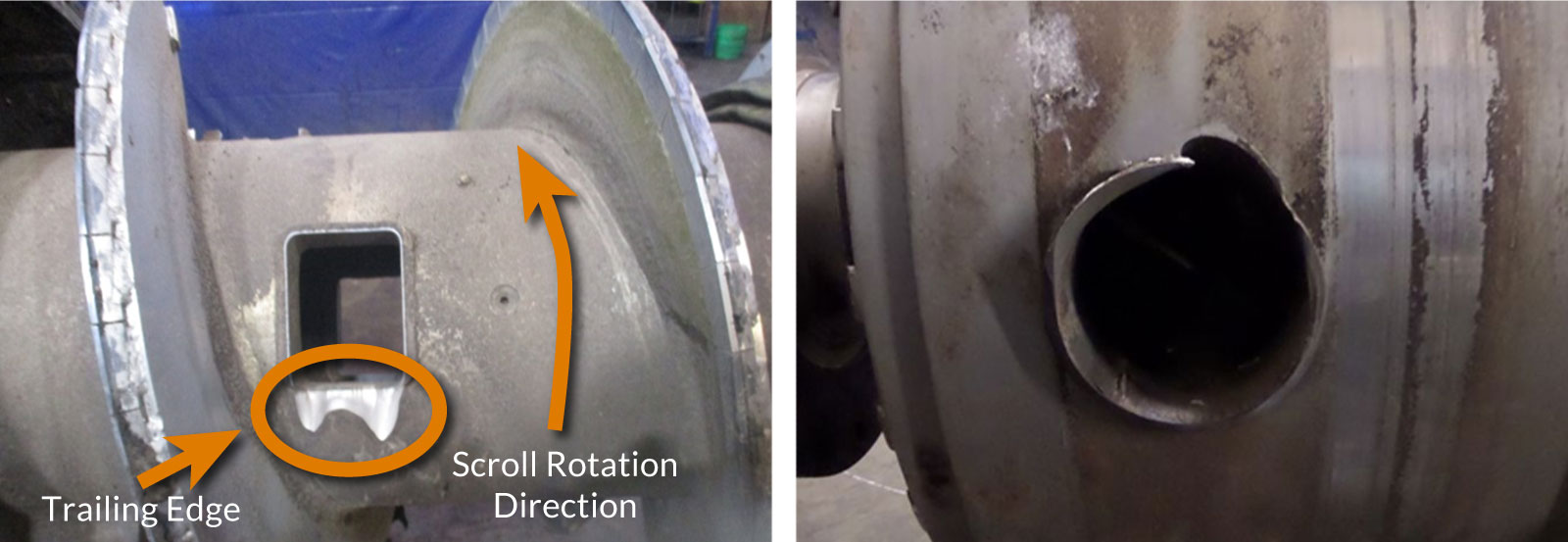

Our innovative design doubles the wear life of the centrifuge feed ports and solids discharge ports. A Centrisys bowl and scroll are designed to operate in two directions. When the operator switches between leading and lagging, the changing bowl direction shifts the wear on the feed ports and solids discharge ports to both trailing edge sides. When a Centrisys centrifuge operates clockwise, the trailing edge rotates counterclockwise.

By switching the centrifuge between leading or lagging directions, equal wear is applied to the feed ports and solids discharge ports. The direction change doubles the wear life of the ports and reduces the maintenance intervals needed on your centrifuge. All Centrisys feed ports and solids discharge ports are constructed with solid tungsten carbide to prolong their life expectancy.

Left Image: This centrifuge had an abrasive application and the feed port has worn through. The damage to the feed port could have been prevented if the centrifuge bowl direction was changed before the feed port was worn through.

Right Image: This solids discharge port shows damage from an object or a very abrasive material that ran through the centrifuge.

What controls a decanter centrifuge to operate in a leading or lagging direction?

The Rotodiff® hydraulic backdrive controls the direction as either leading or lagging. A hydraulic backdrive operates either clockwise or counterclockwise depending on the scroll flighting direction. When the correct hydraulic backdrive direction is set, the centrifuge leading and lagging is determined by the direction of the bowl speed.

How can you tell if your centrifuge is operating in a leading or lagging direction?

Once the centrifuge is operating, the differential speed determines if the centrifuge is operating in a leading or lagging direction. Differential speed is the speed difference between the bowl and scroll. A centrifuge bowl operates at 3,000 rpm. If the differential speed is 1 rpm and the scroll speed is 2,999 rpm, then the centrifuge scroll is lagging. If the differential speed is 1 rpm and the scroll speed is 3,001 rpm, then the centrifuge scroll is leading.

Can a gearbox-driven decanter centrifuge run as leading or lagging?

No. Decanter centrifuges using a gearbox backdrive cannot operate in both leading or lagging directions. Gearbox-driven designs only allow the bowl to rotate in one direction.

- Planetary gearbox centrifuges normally run lagging.

- Cyclo gearbox centrifuges often run leading.

When should you change the centrifuge bowl direction?

For most applications, the centrifuge feed ports and solids discharge ports are designed for 15,000 operating hours. By changing the Centrisys decanter centrifuge’s bowl direction at 15,000 operating hours, you extend the feed ports and solids discharge ports lifespan up to 30,000 operating hours before you are required to rebuild the rotating assembly.

Regular inspections of feed ports and solids discharge ports are critical to understanding how your application affects the wear of the ports. Based on the wear pattern, you may need to change the bowl direction from leading or lagging sooner than expected. On the solids discharge ports, you can visually see the wear pattern by opening the centrifuge cover. For the feed ports, operators can insert a boroscope into the centrifuge feed tube to examine the wear pattern. If there is a heavy wear pattern, switching the bowl direction allows the centrifuge to continue operating without a service or a repair interval. When there is equal wear damage on both edges of the feed and discharge ports, or if there is extreme trailing damage, it is time to send the rotating assembly in for a rebuild.

If you are unsure based on looking at the wear pattern if it is safe to continue using your decanter centrifuge, contact a Centrisys service technician. We can easily evaluate the condition and safety of the centrifuge ports through a centrifuge field service call.

How do you switch your centrifuge from leading to lagging (and vice versa)?

To change a Centrisys decanter centrifuge from leading or lagging, the bowl speed direction has to be changed from clockwise to counterclockwise. You can perform this by either the VFD or by reversing two of the three main motor wires (phases). An operator can swap the wires on site. If you are unsure what wire to switch, contact our trained service technicians.

Do you have questions on the leading and lagging direction of the bowl on your Centrisys dewatering centrifuge? Centrisys/CNP’s experienced service technicians are always available to assist you. Contact the experts at Centrisys/CNP today.