Centrisys/CNP Introduces New Name for Nutrient Recovery Technology

Midwest-based Centrisys/CNP has introduced a new name for one of the company’s nutrient recovery technologies, previously called AirPrex®, which will now be called MagPrex™ in North American markets.

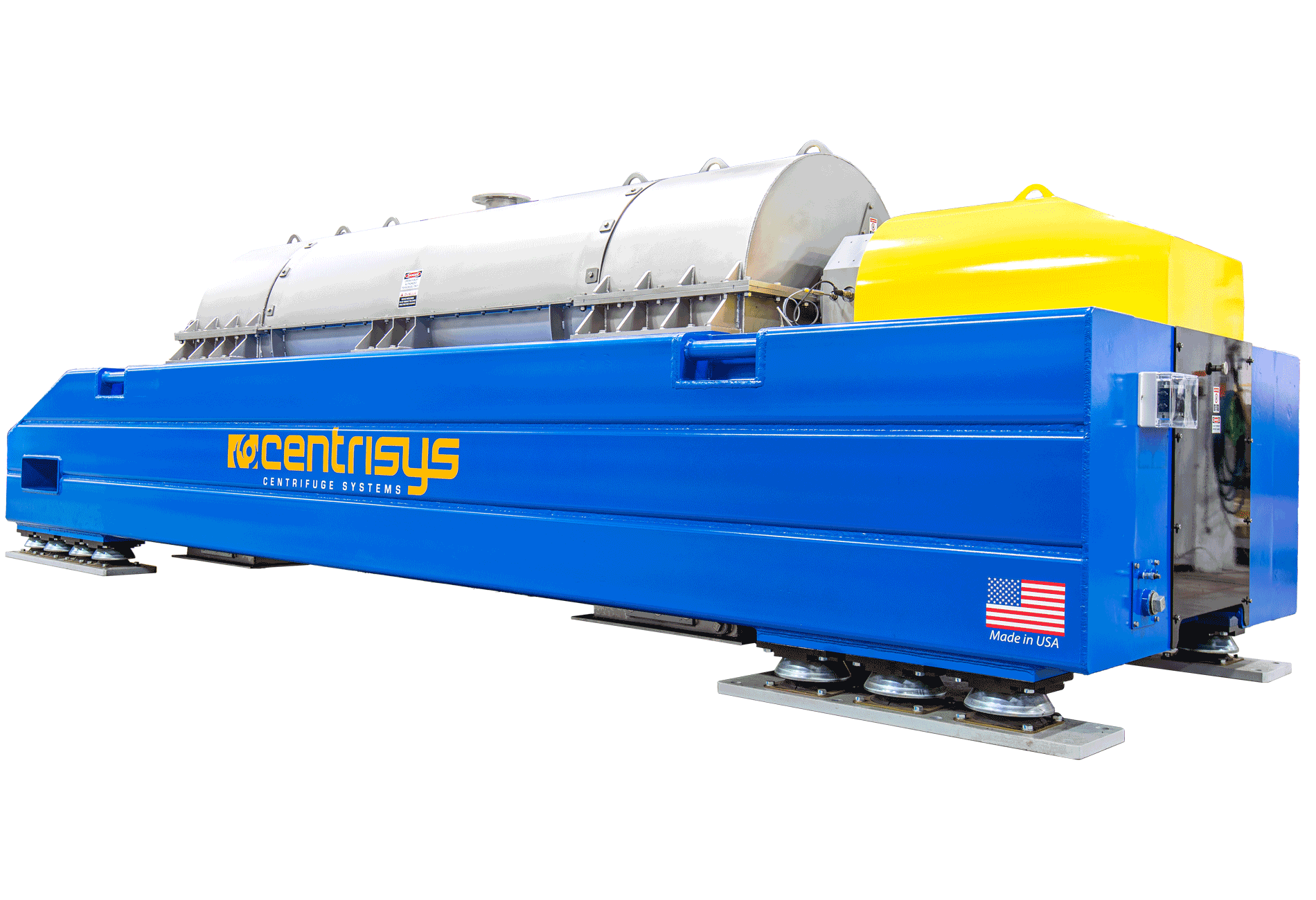

KENOSHA, Wis. (September 23, 2020) Centrisys/CNP, a leading North American manufacturer of decanter centrifuges and advanced biosolids treatment technologies announced today that it has parted from its Germany-based partner, CNP Cycles GmbH, and has introduced a new name for the nutrient recovery technology previously called AirPrex®. CNP – Technology Water and Biosolids Corp. (CNP’s) pioneering process for wastewater treatment plant biosolids optimization and phosphorus recovery is now called MagPrex™ in North American markets.

Since first introducing AirPrex in North American markets in 2014, Centrisys/CNP has made significant improvements to the nutrient recovery process. With six installations to date, including the largest installation located at Denver’s Metro Water Recovery Robert W. Hite Treatment Facility, Centrisys/CNP has kept an acute focus on leading all engineering, manufacturing, and project management activities within its U.S. facilities.

“Our initial nutrient recovery technology introduction took place nearly 15 years ago, and over the years, we’ve made significant improvements to the system that provides superior results in both municipal and industrial applications,” said Gerhard Forstner, President of CNP. “We’ve dissolved the partnership with our Germany-based partner to build on the strength of our U.S.-based initiatives and learnings. Changing our nutrient recovery technology’s name to MagPrex signifies our commitment to continued innovation and ensures the best efficacy and the best value for all of our North American customers.”

MagPrex forms struvite by stripping out CO2, elevating the pH and adding MgCl2 to augment Mg2+. The technology is installed between the anaerobic digester and before the dewatering equipment. The process converts the orthophosphate contained within the digestate into struvite crystals, which can then be harvested from the bottom of the reactor and utilized as a beneficial fertilizer.

MagPrex removes struvite while significantly improving treatment efficiency, including:

- Reduced polymer consumption up to 30 percent

- Reduced disposal costs up to 20 percent

- Reduced phosphate recycle loads up to 90 percent

- Reduced maintenance costs up to 50 percent

- Increased revenue from fertilizer up to 20 percent

- No sodium hydroxide required for pH change

Forstner added, “Our team has worked hard on the evolution of MagPrex and understands the uniquely complex and highly technical needs of our North American customers. As a U.S.-based manufacturer and technology provider, we’ve addressed critical factors in wastewater reclamation plants and industrial applications by leveraging our extensive experience, unique process, and cost efficiencies.”

The adverse effects and costs associated with struvite precipitation in equipment can be detrimental for treatment plant operators. Using the MagPrex system, operators can prevent crystallization in their biosolids train and reduce phosphate recycling by up to 90 percent.

Complementing Centrisys/CNP’s portfolio of dewatering and sludge thickening decanter centrifuges, the company’s advanced biosolids treatment portfolio includes MagPrex, CalPrex™, a phosphorus recovery technology; and PONDUS™, a Thermal Hydrolysis Process (THP).

For more information about Centrisys/CNP and MagPrex, visit www.centrisys-cnp.com.