Centrisys Completes Wastewater Resource Recovery Efficiency Updates in Two New York Locations

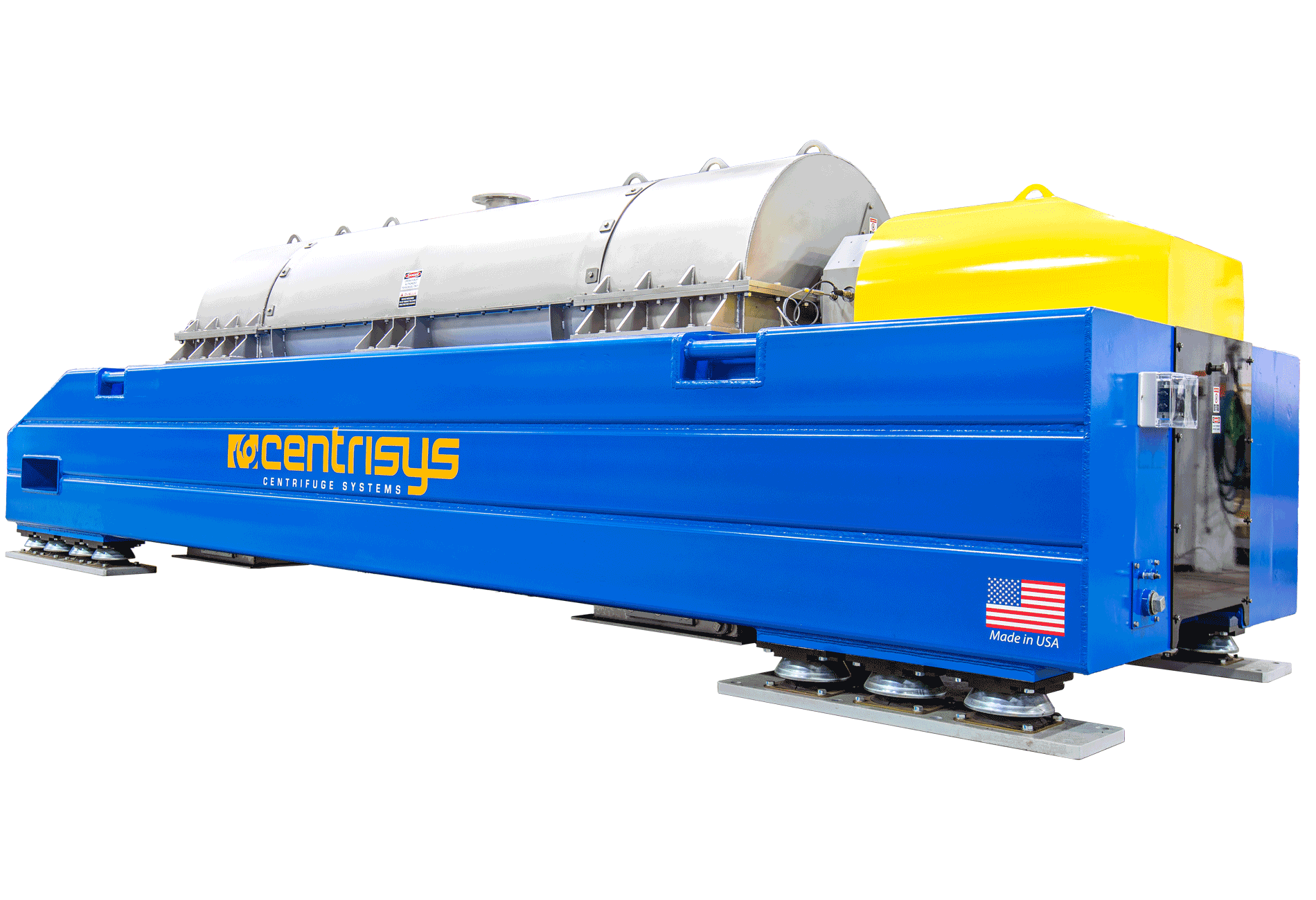

Midwest-based Centrisys provided the New York City Department of Environmental Protection with 32 CS26-4 Centrisys decanter centrifuges to improve the efficiency of the wastewater treatment process.

KENOSHA, Wis. (February 24, 2020) – Centrisys/CNP, a leading North American manufacturer of decanter and thickening centrifuges and dewatering systems, announced today that the $67M comprehensive energy-efficient upgrade at two of New York City’s largest wastewater treatment plants is now complete. As part of a series designed to improve pollution control and treatment efficiency, the NYC Department of Environmental Protection chose to install 32 American-made CS26-4 Centrisys decanter centrifuges.

- The Wards Island Wastewater Treatment Plant is the second largest of the 14 wastewater treatment facilities in New York City, serving nearly 1 million people.

- Hunts Point Wastewater Resource Recovery Facility in the south Bronx cleans more than 200 million gallons of wastewater produced by 700,000 residents every day of the year.

Centrifuges are used in the wastewater treatment process to dewater solids (sometimes called “sludge”) after anaerobic digestion. The older centrifuges were removed and replaced with newer models in groups of four to ensure the continued operation of the plant throughout the project that began in 2015. The new Centrisys centrifuges will consume 60% less electricity, and reduce 826 metric tons of greenhouse gases annually between the two plants. To date, the upgrade has resulted in savings of $1.1 million per year in power, polymer, and biosolids disposal costs and has greatly improved NYC’s dewatering operational efficiencies.

“With more than 30 years in business, the NYC project exemplifies what our team of engineers can do,” said Michael Kopper, president and chief executive officer of Centrisys. “We take great pride in our technology. Putting systems in place that have an evolving impact on the communities it serves while reducing the environmental footprint and cost of the wastewater treatment process, is of utmost importance.”

The Centrisys engineering team integrated a centrifuge stand, diverter gate, and interconnecting pipework into the NYC plant design. These design elements created a “drop-in-place” centrifuge system, allowing for easy integration with only a few minor modifications to the existing floor plan.

Andy Torres is the Centrisys NYC Project Manager who assisted with the project upgrade and worked most closely with the municipality. “Although this was a challenging project due to the age of the older system, design of the facilities, the amount of energy required, and the sheer number of individuals dependent on the technology to continue working throughout upgrades, we knew our decanter centrifuges were the ideal solution for NYC,” said Torres.

Additional plant updates included:

- Ancillary equipment, including sludge and polymer feed pumps with associated instrumentation and controls.

- A new build of an operator workstation equipped with an online solid monitoring system and a new motor control center.

- Replacement of piping, specialized pumps, valves, and other wastewater equipment that work in direct support of the centrifuges.

- Additionally, lighting fixtures in the centrifuge room, the control room, the conveyor room, and the polymer bulk storage area will be upgraded to more energy-efficient models.

In July 2017, the Wards Island Process Control Laboratory conducted a test that showed Centrisys’ CS26-4 centrifuge installation demonstrated better than specification performance results.

For more information about Centrisys and the CS26-4 Centrisys decanter centrifuges used in the NYC project, visit www.centrisys-cnp.com.